LITHIUM-ION BATTERY Slurry Pump

Pumps for Lithium-Ion Slurry Process in Battery Production

NETZSCH Pumps & Systems offers innovative pumping solutions for lithium slurry transfer in the lithium-ion battery manufacturing process. With this pump, you increase the efficiency of pumping lithium slurry process.

The need for batteries is always growing. Which also indicates an increasing desire to increase production efficiency. The proper pump must be chosen since, among other reasons, lithium is one of the most demanding pumping media. This is because lithium is a reaction-sensitive material, which makes it one of the most demanding pumping media. Choosing the right pump was also a challenge faced by an Indian battery manufacturer.

As a global specialist in complex fluid management, NETZSCH Pumps & Systems has specialised on pumping demanding media. Thereby we promise you Proven Excellence - outstanding performance in all areas. We will show you how to pump lithium slurry efficiently and simultaneously gently while complying with the strictest safety regulations.

Individual Consulting

Lithium-ion slurry processing presents difficulties for pumps.

The lightest metal and element with the lowest density is lithium. Due to its extreme reactivity, it does not exist in elemental form in nature. Lithium only remains stable in dry air for a very long time at ambient temperature and then slowly reacts to generate lithium nitride. A matt grey lithium hydroxide coating soon disintegrates on the surface in humid air. Lithium slurry pumps are also significantly challenged by this. Elements of lithium, like all alkali metals, react with moisture on the skin and cause severe burns. The Chinese battery producer also had to deal with issues.

However, lithium is essential, especially for the creation of batteries. Lithium positive ions are moved between the cathode and the anode of batteries by passing through the electrolyte. These are in charge of the battery's charging and draining. The need for lithium is growing along with e-mobility. In order to meet this demand in the future and avoid supply constraints, production efficiency must be raised. The selection of proper pumps is a key factor in enhancing efficiency.

Considerations to make while choosing a pump to transfer lithium-ion slurry.

A highly viscous solution of lithium carbonate and water is known as lithium slurry. In other words, it reduces flow rate since it is viscous and pumps and pipes must overcome a high amount of resistance. Sand, clay, and other solid materials that are abrasive and wear down the inside surfaces of pumps and pipes are also frequently found in lithium slurry. Lithium is also corrosive due to its high salt content. This may result in harm and leaks, costing you money in repairs and downtime.

Lithium sludge also has a tendency to settle. This implies that over time, the mixture's sediments and water could separate, leading to pump clogs and blockages. Due to its high viscosity, abrasiveness, corrosiveness, and solids separation, lithium slurry poses a challenge for pumps. Used pumps must be strong, rust-proof, and able to withstand the higher strains brought on by pumping lithium slurry. As a leading expert in complex fluid management, NETZSCH has the best option for you in its portfolio for the safe pumping of lithium.

How to safely and effectively pump lithium slurry during a battery manufacturing process.

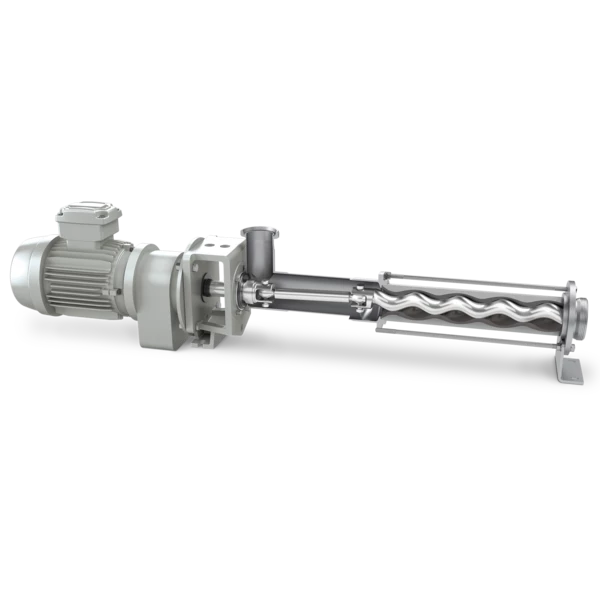

Therefore, a battery manufacturer in India relies on NEMO® progressing cavity pumps in stainless steel design with a flexible rod from NETZSCH. The main feature of this pump type is the underlying progressing cavity principle. A helical rotor rotates in an oscillating manner in a geometrically matched stator. This results in uniform delivery chambers in which the medium is moved continuously and gently from the suction to the discharge side. Hence, you can pump lithium slurry without pressure fluctuations, pulsation or shear forces.

To meet the high requirements of the reaction-sensitive light metal, a flexible rod connects the drive to the shaft instead of open or oil-filled joints. The rod is shrunk to the rotor and the connection point of the drive shaft. This makes both transitions hermetically sealed. Since no components are in contact with each other, the flexible rod hardly wears out and requires neither seal nor lubrication. Thus, there are hardly any maintenance costs for you. For the same reason, a PTFE sleeve seal without oil is used as a coupling insert.

In addition, the polished stainless steel surfaces ensure that the medium cannot get stuck. This reduces contamination to a minimum. In addition, this makes the pump particularly easy for you to clean, which is an essential prerequisite in a chemical process. To accommodate the highly explosive mixture of the medium, the pumps are driven by an electric motor. Therefore, the Indian battery manufacturer increased its efficiency significantly and, at the same time, its safety. Let our experts advise you and find the right pump solution for your application.

NEMO® BH hygienic pump in compact block design

- Medium: Lithium slurry

- Capacity: 0.9 to 2.4 m3/h

- Temperature: 20 °C

- Pressure: 8 to 12 bar

- Viscosity: 3.000 to 35.000 mPas