APPLICATIONS & SOLUTIONS

Chemical Pumps

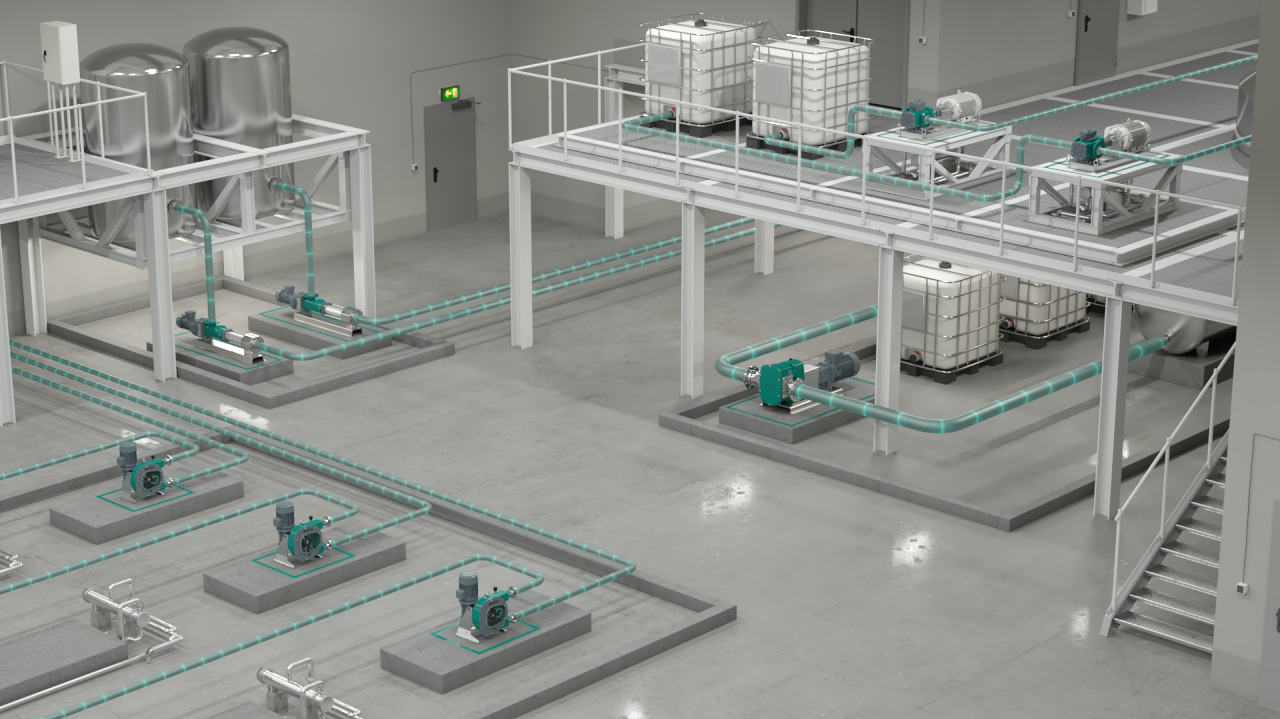

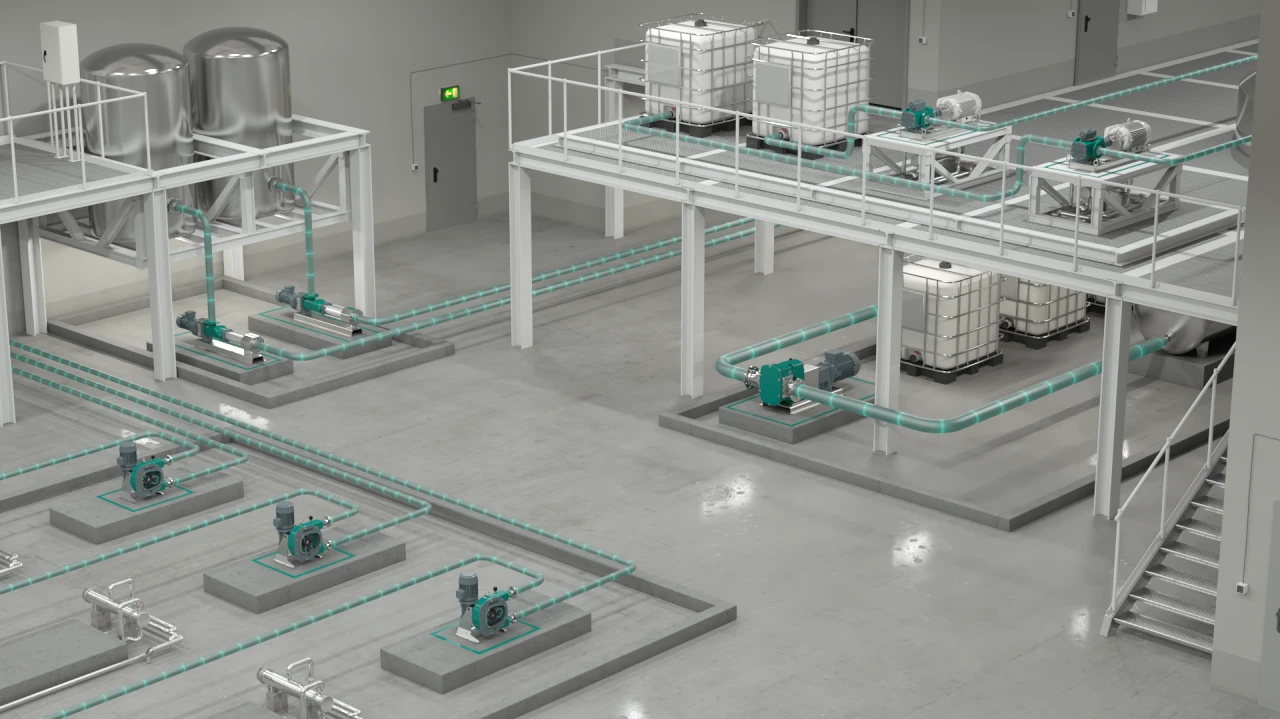

Chemical Process Pumps for the Chemical, Paper and Pulp Industries

As a global leader in the manufacture and supply of rotary positive displacement pumps, NETZSCH designs and develops the ideal chemical process pumps best suited for various chemical processes including pulp and paper production.

With our chemical process pumps, you can effectively convey even the most challenging and complex liquid media. Viscous, aggressive, and corrosive fluids that are hazardous to health and the environment, fluids that contain solids and are abrasive, require pumps that can handle complex media robustly and safely.

We globally develop customised and sophisticated solutions for you in the chemical, pulp and paper sectors. Fluids that are hazardous to health and the environment, highly viscous products, products containing solids or sensitive products require pumps that can handle even the most challenging media in hermetically isolated systems.

NETZSCH makes no compromises when it comes to process safety and reliability. Our customer satisfaction and peace of mind is always our top priority. Together with our customers, we strive to deliver and co-create optimally tailored chemical process pumps best suited to your requirements.

Individual Consulting

Find the right pump for your chemical process, pulp and paper applications!

NETZSCH is among the best chemical process pump manufacturers in the world. Our customer satisfaction, with safety, reliability and process efficiency are of prime importance and our top priority. Our family of rotary positive displacement Pumps such as, NEMO® progressing cavity pumps, TORNADO® rotary lobe pumps, PERIPRO peristaltic hose pumps, NOTOS® multi screw pumps, dosing and barrel emptying solutions, guarantee you the right solution for many of your applications in the chemical process plants.

„Handling a wide range of chemicals to natural minerals with complex fluid properties is the challenge of almost every chemical industry.

NETZSCH is your preferred partner to offer the best chemical process pump solutions with our wide range of Industrial Rotary Positive Displacement Pumps & long years of rich global experience in providing complex fluid handling solutions in the chemical processing industry.“

NETZSCH chemical pump technologies for various chemical processes in the paint and varnish Industry

With NEMO® progressing cavity pumps, you can continuously convey abrasive and corrosive media in paint and varnish manufacturing, pulp and paper, and similar industries. In addition, the NEMO® progressing cavity pump enables you to achieve precise dosing while handling viscous liquids.

Due to the innovative design of the FSIP - NEMO® Progressing Cavity Pump, maintenance and service can be carried out in place, without dismantling pipelines, saving you time and the associated maintenance costs.

The TORNADO® T.Proc® rotary lobe pump with its small footprint and compact design is well suited for high pumping efficiency and long service life when pumping abrasive media and in applications like construction chemicals industry. You can pump with ease, liquids like paint dispersions, emulsions and primers, which have high solids content with high reliability. This way, you can reliably convey complex media for chemical processes with the highest possible system efficiency.

The PERIPRO Peristaltic Hose pump also finds several applications where, there are applications with complex fluids and that which demand seal less pumps. The special roller design of the rotating element and the specially made hoses guarantee long reliable service life with minimal use of lubricants in the pump head.

Precise mixing and dosing using chemical dosing pumps in chemical processes, gluing and bonding applications.

Precise dosing plays a critical part in metering and mixing complex fluids or in complex duty conditions, in several processes of manufacturing. With the two chemical process pump technologies, NEMO® progressing cavity pumps and PERIPRO Peristaltic hose pumps, you can dose a wide variety of highly viscous, aggressive, corrosive, and sensitive chemicals without interruption, with the lowest level of pulsation and to the precision of + or -1%. This is made possible by the unique design of the chemical process pumps offered by NETZSCH. The NEMO® barrel emptying systems coupled with the NEMO® Dispensers assure emptying the barrels/drums/totes leaving very low residues and thereafter precise and controlled mixing and dosing of liquids that are made up with 2 Components in certain gluing and bonding applications.

Chemicals pump used for continuous and reliable conveying of chemicals in paper and pulp processing.

The NEMO Progressing Cavity Pumps have been used over many decades with a high level of reliability in paper manufacturing processes. Due to the continuous uninterrupted operations of paper machines, the reliability and efficiency of the Pumps are of high value to our customers. The NEMO Progressive cavity pumps are the proven solution for handling, sticky, viscous, abrasive, and shear-sensitive liquids used in the paper manufacturing process.

The TORNADO® rotary lobe pumps help you convey complex media like kaolin slurry or coating slurry. We select the ideal and compatible materials for construction optimally matched to suit the pumped liquid and that enables you to achieve long running times with low maintenance. These pumps are provided with easily accessible and removable casing to perform maintenance and cleaning, which shortens the service times, especially with abrasive and highly viscous products.

Safe, gentle and efficient conveying of highly reactive substances with the best chemical process pumps

Liquids such as lithium slurries are in high demand due to the rapidly growing EV battery industry. These lithium-based liquids are highly corrosive and aggressive media and pose challenges when conveying them. The NEMO® progressing cavity pumps in stainless steel design and magnetically coupled drive systems enable to pump these highly reactive liquids and slurries efficiently making them the best chemical transfer pumps in battery production process. Our pumps help to transport the medium continuously and gently, without pressure fluctuations, pulsation or shear forces. This keeps maintenance and servicing costs extremely low, even with demanding media.

Uninterrupted and safe discharge of numerous types of hazardous substances

Pumping of fatty acids in the chemical industry is subject to stringent legal requirements. With the innovative TORNADO® T.Proc® rotary lobe pumps, you can pump the most complex types of hazardous substances in compliance with all regulations. The unique design enables you to safely empty and fill tanks or trucks and ensures a particularly long service life. Even solvent-contaminated or mixed media pose no problems for the TORNADO® with the full metal design versions. This means that you expose neither personnel, consumers, nor the environment to unnecessary danger.

NETZSCH Pumps being the best chemical process pump manufacturer, we provide engineered and customized solutions to your chemical process pump needs.

Below are the application success stories with our chemical process pumps in the segments of chemical, paper, and pulp industries: