Shampoo Transfer Pumps

Pumping Solutions in the Soap & Shampoo Manufacturing Process Industry

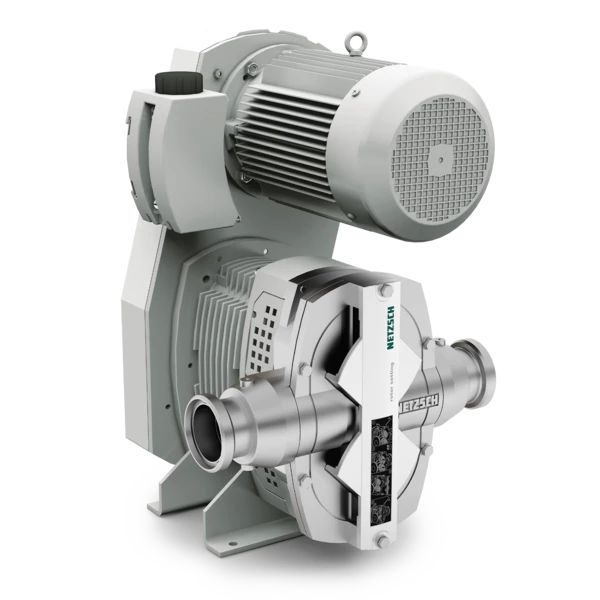

NETZSCH Pumps & Systems manufactures specially designed T.Sano® lobe pump to increase mobility and efficiency in the production of shampoo and soap manufacturing process. Choose the best compact and powerful shampoo transfer pumps for your shampoo and soap processing industry.

NETZSCH offers high-quality industrial soap & shampoo transfer pumps for various soap & shampoo manufacturing processing industries in India. The price of production space has increased significantly in recent years. Therefore, most companies aim to get the most out of the available space and thus increase production efficiency. But where can production space be saved, and how can efficiency be improved?

These questions were also asked by an Italian skincare products manufacturer who produces soaps and shampoos, among other things. NETZSCH Pumps & Systems, the global specialist for handling complex media, had the answers. We show you how shampoo transfer pumps save production space and become more efficient by replacing your current shampoo pump.

Individual Consulting

Shampoo transfer pump process: Benefit by reducing the production area

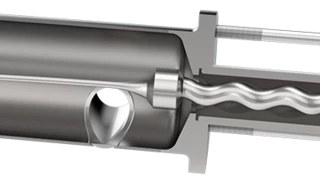

An Italian care products manufacturer produces soaps and shampoos, among other things. So far, they have been using progressing cavity pumps for this application, which require significantly more space than other technologies.

In the context of optimizing performance, space is increasingly recognized as a valuable resource and represents a cost factor. By reducing the required space, companies can cut rental costs, energy costs, and operating costs. The less space required, the more efficiently resources can be used. In addition, saving space increases your flexibility.

A reduced production area allows you to react flexibly to changing market conditions. When demand drops, you can quickly adjust production without having large, unused spaces. This increases agility and competitiveness. In addition, a reduction in production space can lead to increased efficiency.

Companies can produce the same amount or even more in smaller spaces by optimizing production processes and using new technologies.

Challenges of shampoo pumping in the process industry

There are different challenges to consider when pumping shampoo. The raw materials for the shampoos must be pumped from tanks to the production lines at two bars with a flow rate of between one and six cubic meters.

However, shampoos tend to form foam when pumped. While foam is desirable when showering or washing hair, it should be avoided in production. This can affect the pump's functionality by accumulating in the conductors and reducing the flow rate. It can also lead to an increased wear rate of the pump.

In addition, shampoos contain various chemical components such as surfactants, fragrances, and preservatives. These can be corrosive or damage the seals and other parts of the pump. Sometimes, this leads to leaks or shortens the life of the pump.

These challenges posed no problems for the progressing cavity pump used at the Italian care products manufacturer. However, the existing shampoo pumps required so much space that the installation, maintenance, and cleaning measures needed to be simplified. That's why the company approached NETZSCH with their requirements.

Shampoo pump reduces space requirements and increases efficiency

Together with the care product manufacturer, the experts from NETZSCH found the optimal solution for saving space and, at the same time, increasing efficiency when pumping shampoo.

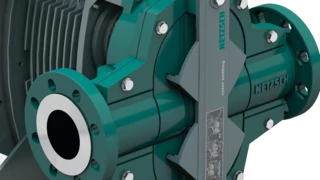

A TORNADO® T.Sano® all metal rotary lobe pump provided the remedy. It is characterized by significantly less installation space than comparable pumps and a belt drive that both drives the lobe rotors and ensures synchronization.

Thanks to this dual function, there is no need for an additional complex gearbox. In addition, the motor can be placed directly above the pumping chamber, which results in a shallow installation depth for you.

In addition, the belt drive runs very quietly, which reduces wear. Since the drive is entirely oil-free, you have no maintenance or servicing to do. This saves you time and money.

The belt drive can be loosened and replaced in a few easy steps if necessary. This reduces your maintenance effort and downtimes to a minimum. The choice of materials also contributes to this: The T.Sano® only uses stainless steel or other special steels for the housing and rotary lobe. The resistant materials thus ensure a long service life and guarantee the long-term availability of the shampoo pump.

The absence of oil and stainless-steel construction also ensures absolute hygiene in manufacturing. For residue-free cleaning of the pump, you can connect the proven CIP process (Cleaning-In-Place) and the SIPprocess (Sterilisation-In-Place). This allows the system to be cleaned or sterilised in a circular or continuous process without prior disassembly.

By replacing the existing pump, the Italian skincare product manufacturer was able to significantly reduce the needed space and increase the efficiency of its production. What are you waiting for? Let the experts of the global specialist for conveying complex media advise you and optimize your process.

TORNADO® T.Sano® all metal rotary lobe pump