biogas Processing Pumps

How Pumps Optimise Your Biogas Production Process

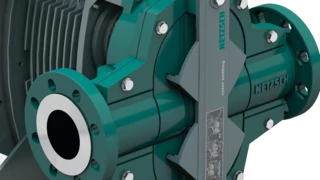

NETZSCH Pumps and Systems is one of the leading manufacturers and suppliers of biogas pumps in India, we offer innovative pumping solutions for the biogas production industry or anaerobic digestion processes. High mixing performance thanks to NEMO® B.Max progressing cavity pump

The conditions in biogas production are extremely challenging for pumps. Many pump systems are not up to handle the harsh and abrasive mass and thus do not deliver the required mixing performance. NETZSCH Pumps & Systems, the global specialist in handling complex media, has developed a special pump for the biogas sector.

We will show you how biogas pump - NEMO® B.Max progressing cavity pump increase the mixing performance and thus optimize your process.

Individual Consulting

Biogas pumps for efficient energy generation with biogas

The demand for alternative energy generation is more significant than ever before. The focus lies on environmentally friendly electricity and heat generation from renewable biomass. Operators worldwide are getting the know-how and the necessary plants from the technology leaders to exploit the advantages of renewable energies, above all biogas utilization.

Unique pumps are needed to generate power from biogas plants efficiently. These would have to reliably convey and mix substrates with a high dry matter content. In this way, waste from agriculture and food production can be efficiently converted into clean energy in addition to energy crops.

How the biogas pumps transfer dry biogas substrates which poses a challenge for pumps

The biggest challenge for biogas pumps in biogas production is substrate composition. Relatively dry components such as chicken manure restrict the flowability. Plant fibers from grain residues, maize, or grass tend to clog, and corrosive slurry attacks the materials.

In addition, biowaste is often used for gas production instead of renewable raw materials. If these are meat scraps or slaughterhouse waste, they have to be hygienic for epidemic protection. This leads to high medium temperatures of up to 80 °C and poses a further challenge for the pumps in biogas production.

NEMO® B.Max progressing cavity pump used in biomass sectors.

The NEMO® B.Max progressing cavity pumps from NETZSCH, specially designed for the complex substrate mixtures in the biomass sector, make it possible to reliably convey and mix even media with a high dry matter content.

Using them ensures the continuous feed to the fermenter required for an undisturbed fermentation process, despite challenging conditions. With the NEMO® B.Max pump series, NETZSCH has adapted the proven progressing cavity technology to the unique requirements of biogas production.

The B.Max pump has a position-optimized feed nozzle that directs the recirculation into the mixing area against the conveyance direction. This creates turbulence in the biomass, which ensures that the individual materials are already mixed when fed in.

By using the pump, you significantly increase your mixing capacity. This process is additionally supported by the coupling rod in the mixing chamber, which is equipped with a screw conveyor. The coupling rod ensures that the sometimes-challenging biomass is reliably transported into the pumping area. The staggered segments of the mixing screw and its high thread pitch ensure that more substrate flows to the eccentric screw than it can transport away.

The result is an intentional, controlled backflow that leads to further turbulence in the material mixture and thus to its homogenization. Depending on the design, pumps of this type can achieve flow rates of up to 70 m³/h and pressures of up to 48 bar. At the same time, the continuous feed to the fermenter saves you the use of a more powerful agitator. Using a NEMO® B.Max pump, you can optimize your process in no time and ensure efficient and sustainable energy production using biogas.

NEMO® B.Max mixing pump in block design

- Medium: Grain waste, Municipal Solid Waste, Napier grass, Chicken manure or Slaughterhouse waste, Press mud

- Temperature: Up to 80 °C

- Capacity: Up to 70 m³/h

- Pressure: Up to 48 bar