NETZSCH Pumps manufactures dosing dispenser pumps are precision instruments used in various industries for the accurate dispensing of fluids, ranging from low to high-viscosity liquids.

Our NEMO® dispenser pumps are known for their reliability, precision, and versatility, making them suitable for applications across pharmaceuticals, food and beverage, chemical processing, cosmetics, and more.

In chemical processing applications, these pumps excel at handling aggressive chemicals and corrosive fluids, thanks to robust construction and corrosion-resistant materials.

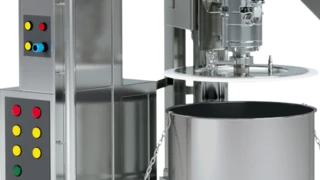

In the food and beverage industry, dispenser pumps are utilized for accurate dosing of ingredients in recipe formulations and for filling containers with liquids of varying viscosity, such as oils, sauces, syrups, and dairy products.

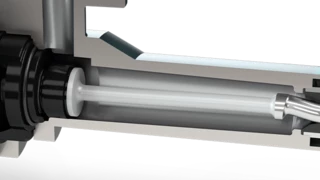

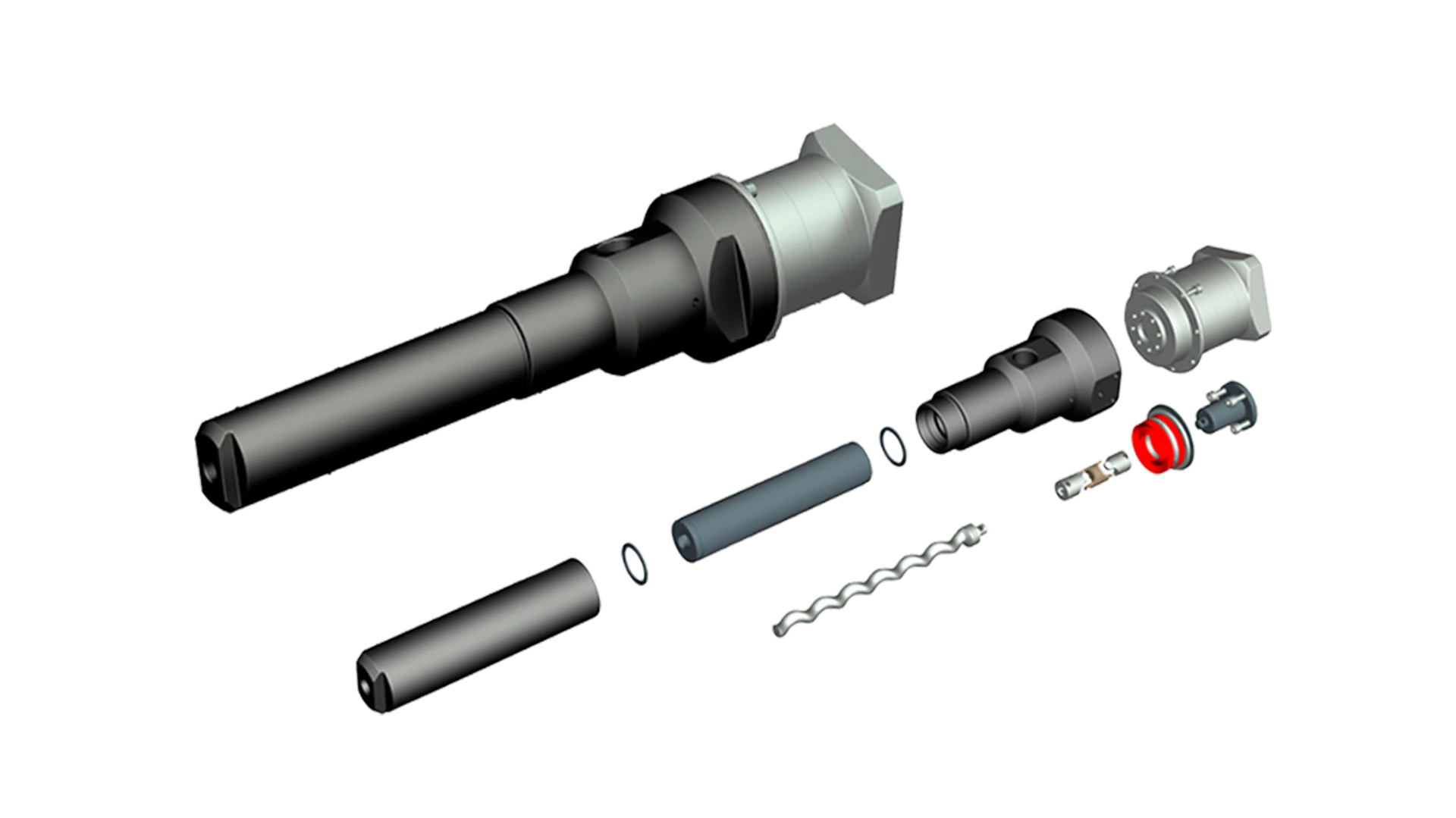

NETZSCH dispenser pumps are an innovative design, which incorporates advanced technologies to ensure consistent and precise dispensing. These pumps often utilize positive displacement pump mechanisms, such as progressive cavity or rotary lobe designs, which provide excellent control over overflow rates and volumes.

Moreover, NETZSCH dispenser pumps are favored for their ease of maintenance and long service life. They are designed with accessibility and serviceability in mind, with features such as quick-disconnect fittings, tool-less disassembly, and easily replaceable components. This ensures minimal downtime during maintenance and reduces the overall cost of ownership.

How do liquid dispenser pumps work in chemical applications?

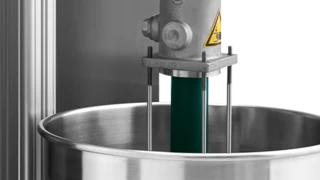

No challenge is too great for the NEMO® dispenser pump. They can easily handle low to high viscosity and abrasive to anaerobic media in a product-friendly manner. Even shear- and pressure-sensitive products pose no difficulties. In addition, the dosing accuracy of approximately one percent and the speed-proportional delivery rate is ensured even with demanding media. This means that you can dose your products completely without dripping. This prevents rejects and thus unnecessary costs.

In addition, the dispensers and manual dispensers impress with their compact design and valve-free dosing method. On the one hand, this prevents increased downtimes, and, on the other hand, the liquid dispenser pump is optimally suited for inhomogeneous liquids and applications in robotics and servo technology. Optionally, the dispensers can also be temperature-controlled. This means you can also quickly convey media that tend to harden or require temperature control.

Individual Consulting

Advantages of Dispenser Pumps

No dripping or stringing even with low-viscosity media

Compact design

Low-pulsation conveying enables highest dosing accuracy

Dispenser Pump Technique

NEMO® Dosing Dispenser Pump Features

- Capacity directly proportional to pump speed

- Dosing accuracy ± 1% volumetric

- Highly versatile in applications requiring robotic and servo technology

- Valve free dosing method

- Optional heating

- Perfect for shear sensitive products such as micro balloons

Worldwide service and support for your liquid dispenser pump systems.

Our service and support do not end with the purchase. From consultation, spare parts, and maintenance to the repair and modernization of your dispenser pump - we support you right from the start.

Thanks to our worldwide service network, we are ready for you around the clock in case of an emergency.

Your contacts and companies at NETZSCH

Any specific questions? Contact us for help or fill in the contact form.