Produits et Accessoires

Pompes à rotor excentré NEMO®

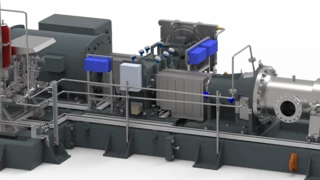

Les pompes à rotor excentré NEMO® ont un large spectre d'applications et trouvent leur utilisation dans tous les secteurs industriels pour le transfert ou le dosage de fluides très variés, de façon continue, sans destruction, sans contraintes, ni fortes pulsations.

Quel que soit le produit à véhiculer : boues, produits chimiques, colles et adhesifs, pétrole ou yaourth , vous trouverez assurément, parmi les 11 types de pompes déclinées en 4 géométries rotor/stator et notre choix d'articulations , l'exécution adéquate à votre application. N'hésitez pas à nous contacter, nous nous ferons un plaisir de vous aider à sélectioner l'exécution idéale!

Individual Consulting

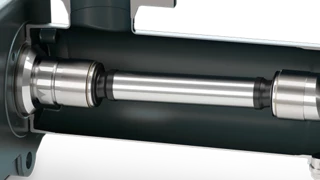

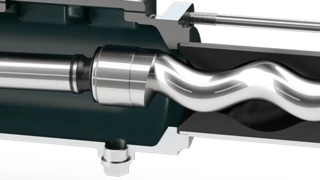

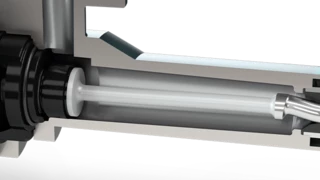

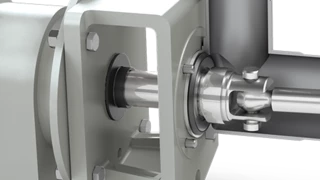

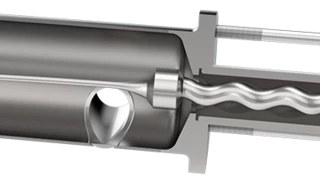

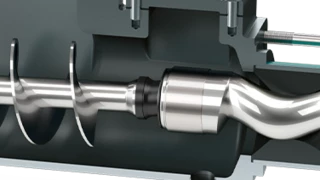

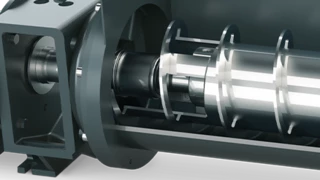

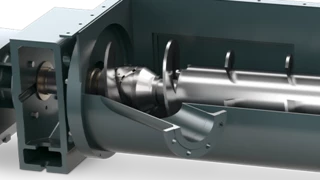

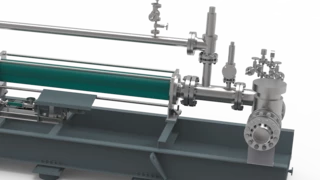

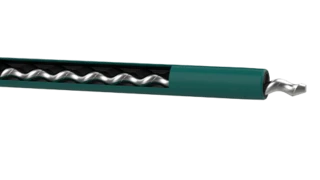

The technology of the progressing cavity pump

Progressing cavity pumps belong to the group of positive displacement pumps. The main components are a rotating rotor and a stationary stator. The rotor, hinged or elastically attached on one side, is a round-threaded screw. On the output side, the axial position oscillates. The hollow stator is elastic and has the same pitch length as the rotor. This leaves conveying spaces between the stator and the rotor, which move continuously from the inlet to the outlet side. The size of the delivery spaces and the associated delivery rate depends on the size of the construction. Except for the rotor and stator, all other components are identical.

This means that if the flow rate or pressure of already installed NEMO®progressing cavity pumps is subsequently changed, they can be adapted to the new operating conditions by simply replacing the rotor and stator. Since the shape of the cavities is always constant, the pumped medium is not compressed. This allows you to pump not only fluids but also solids. Due to the meagre shear forces, you can even pump whole fruits undamaged. Another advantage of the valveless progressing cavity pumps is that they convey continuously and with low pulsation. Even highly viscous and abrasive media can be pumped safely and without problems. They are also suitable as submersible pumps in wells and with open end connections for emptying barrels.