Очистка сточных вод и шлама

Очистка сточных вод и шлама

The NEMO® BP progressing cavity pump with aBP-Module® prevents system downtime in a sewage treatment plant despite the high strength of the sewage sludge.

There are two aspects of wastewater treatment plants at Celle (Germany) which have a direct use: in addition to cleaning waste water, the sewage sludge which arises with the nutrients it contains can be used later as manure in agriculture.

Individual Consulting

Pumps for conveying dewatered sewage sludge

To be able to store and reuse the sludge from a wastewater treatment plant, later on, it has to be processed. At the wastewater treatment plant in Celle, the sludge is first dewatered in an angle press, and flocculant is added. The dry sludge is pumped from the wastewater treatment plant through a pressure pipe with 90-degree bends about 25 metres into a silo. It is then distributed from the silo to agricultural land. The sewage sludge later serves as fertiliser because of the nutrients it contains.

Solid sewage sludge causes daily pump breakdowns

Due to the high strength of the sewage sludge, there were frequent blockages and bridging in the wastewater treatment plant, resulting in operational downtimes. The downtime amounted to a total of three to four hours per week. The wastewater treatment plant needed a reliable pumping system to prevent plant shutdowns and the associated operational failures.

NEMO® BF hopper pump with aBP modules® conveys solid sewage sludge

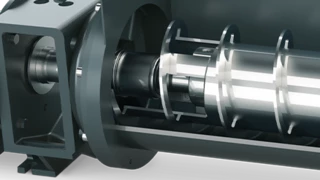

NETZSCH developed the NEMO® BF hopper shaped pump with aBP-Module®, especially for highly viscous, stab-resistant and crumbly media. This consists of a top shaft with flat spoked wheels mounted on the inside. The wheels sit deep in the shaft and close to the wall. If they rotate, this affects the material being conveyed, as if the entire sides of the shaft were moving. Thus, using the NEMO® BF pump to convey solid sewage sludge prevents clogging and bridging.

At the wastewater treatment plant in Celle and many other operators, the pump system with the integrated bridge breaker has proven itself in continuous use. The robust hopper pump increases operational safety and prevents plant shutdowns even without tiresome inspection trips to the conveyor.

NEMO® BF hopper shaped pump with aBP-Module®

- Medium: Sewage sludge

- Throughput volume: 2 up to 5 m³/h

- Rotations speed: Under 30 rpm

- Pressure: 12 up to 15 bar

- Dry matter contents: 25 to 35 %

- Viscosity: Between 10 and 22 Pas