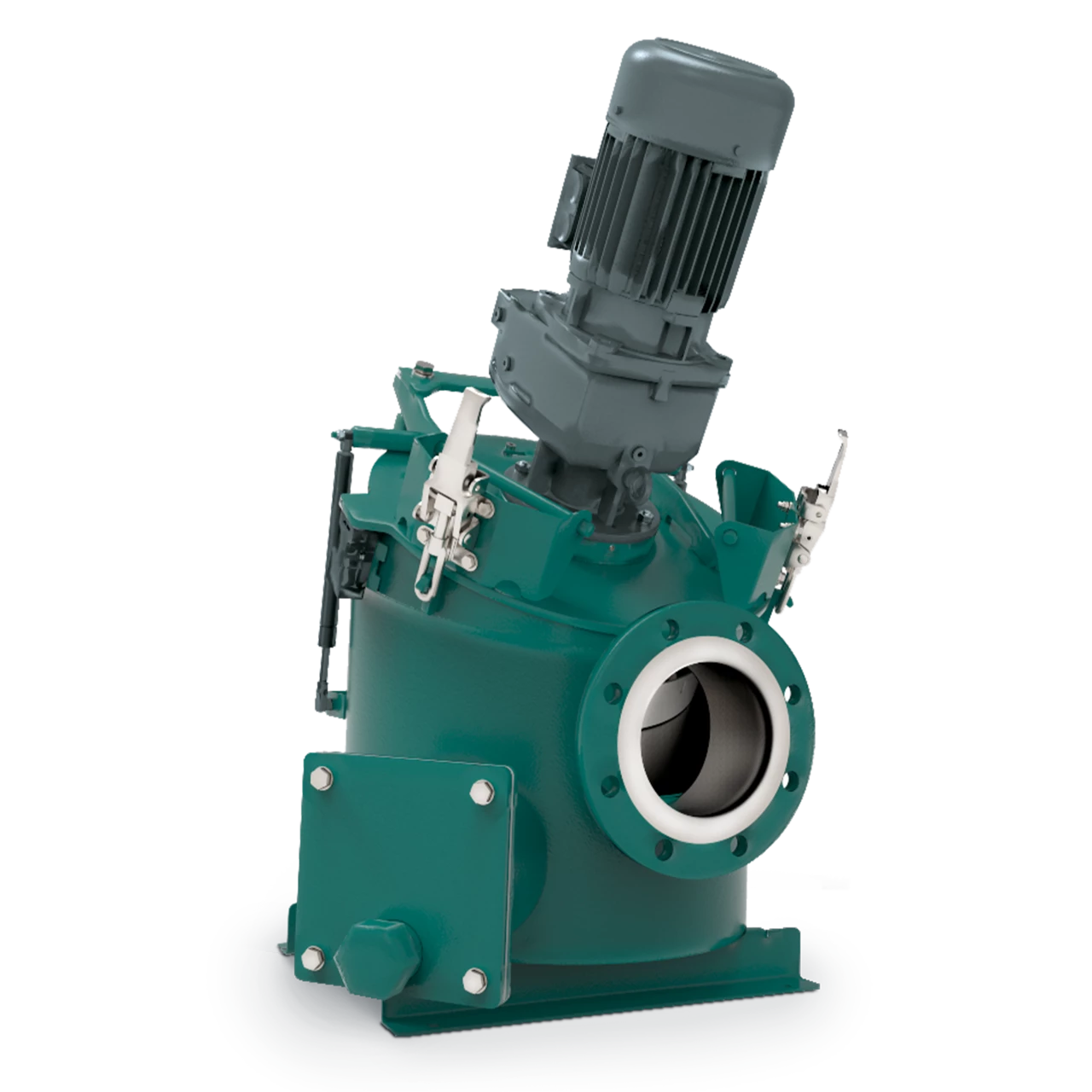

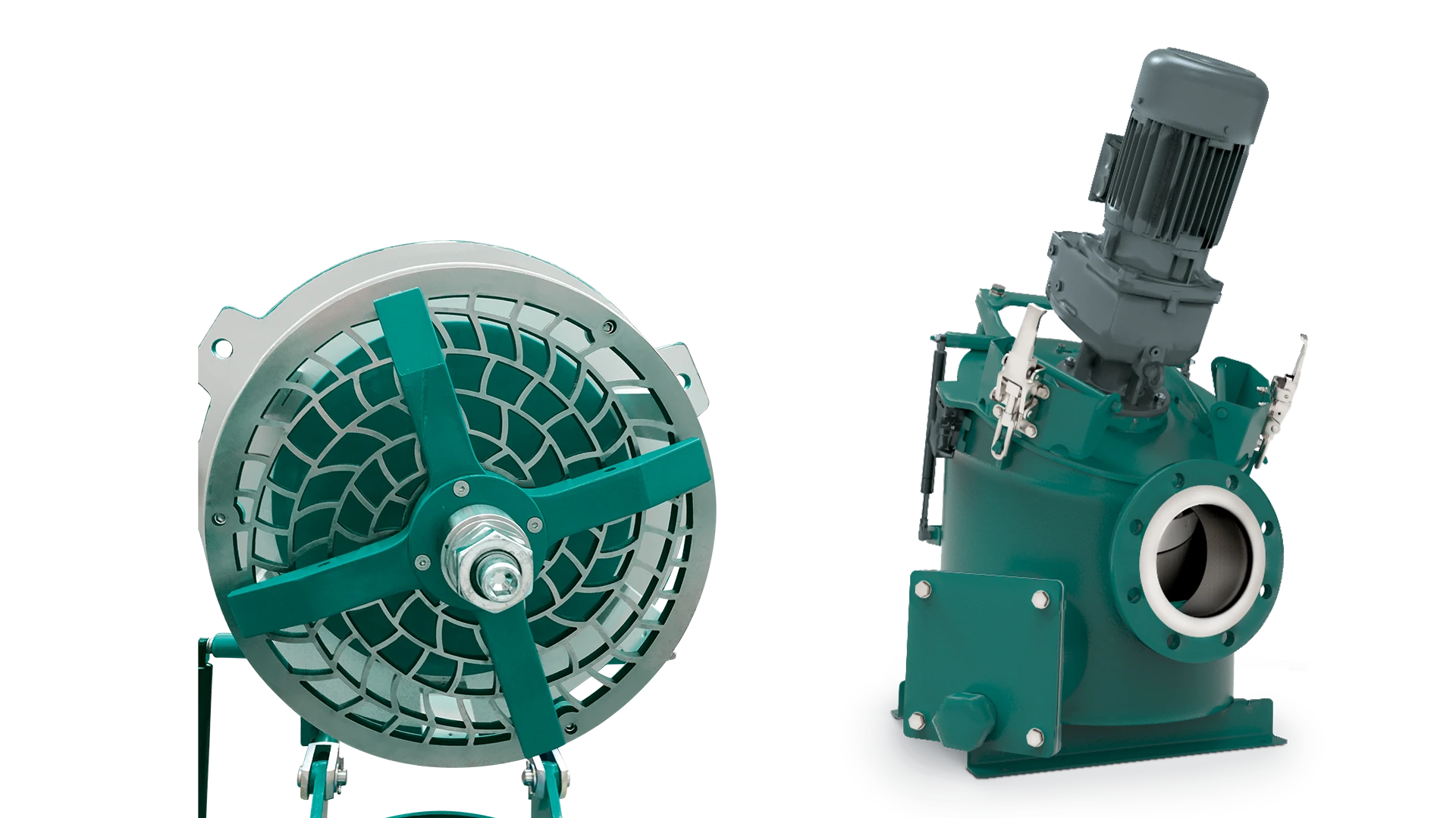

Grinding systems protect your system. With the universally applicable M-Ovas® cutting place macerator, you can prevent possible damage to your pump caused by impurities. The individually adjustable cutting place prevents the entry of substantial solids into the following systems such as pumps. It is ideal for use in biogas or wastewater plants.

Impurities are reliably ground up or separated from the medium. Objects such as stones can be easily removed from the integrated separator container with separate clean-out port and drain openings. This reliably prevents damage to the following aggregates. The crushable parts are pressed against the cutting place by the flow and ground there by the rotating head of the cutter until they are flushed through the openings and do not pose a danger to your system. The cutting plate is convincing due to its robustness. It is made of a wear-resistant special alloy, hardened and finely ground on the contact surface with the cutter head. Available in different hole sizes for the individual requirements of your application, the steel milling head is equipped with positive-fit carbide cutting edges. In addition, the cutting plate can be turned over in case of wear. Thanks to the quick and straightforward disassembly, you save time as well as money while at the same time ensuring maximum protection for your pump.

Individual Consulting

Advantages

Integrated clean-out port

Cutting plate can be used on both sides

Particularly maintenance friendly

Technique

Worldwide service and support for your pump and system

Our service and support do not end with the purchase. From consultation, spare parts and maintenance to the repair and modernisation of your pump - we support you right from the start.

Thanks to our worldwide service network, we are ready for you around the clock in case of an emergency.

Your contacts and companies at NETZSCH

Any specific questions? Contact us for help or fill in the contact form.