Chili & Tomato

Pumping Chilli and Tomato Sauce Without Reducing Quality

This is how you reduce your energy consumption and also convey gently

High quality and, at the same time, inexpensive food is a contradiction for you? Not with NETZSCH Pumps & Systems. As a global supplier in complex fluid management, we offer you the optimal solution for gentle and efficient pumping of chilli and tomato sauce in the food industry.

We will show you how to reduce your energy consumption when pumping chilli and tomato sauce and how to pump gently and efficiently simultaneously. This is how you benefit from using a NEMO® progressing cavity pump in your production.

Individual Consulting

Do you want to pump chilli and tomato sauce efficiently in your production?

The demand for high-quality food is constantly increasing. Awareness and autonomy over one's diet are among consumers' goals today. In practice, however, the path to the goal often begins pragmatically: First and foremost, what tastes good and fits into the budget is eaten. To prevent a reduction in quality without increasing production costs, pumps are needed that convey particularly gently and efficiently. This also applies to chilli and tomato sauce, which is used in numerous dishes such as pasta, pizza or other foods. One company used a screw pump in manufacturing to pump the chilli and tomato sauce. However, this did not achieve the required flow rate and, at the same time, significantly reduced the product quality due to shearing.

How to prevent quality degradation when pumping chilli and tomato sauce

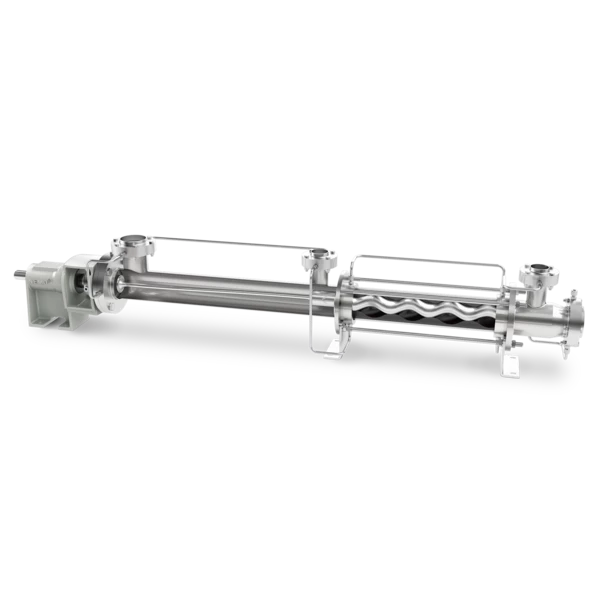

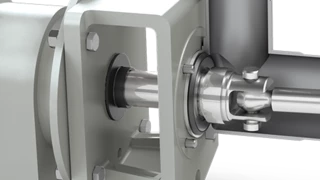

The first pump transports the medium into the heater at a temperature of 65 °C and then the second pump conveys the product at 98 °C into the heat retention section, which is upstream of the heat exchanger (cooler). The progressing cavity pumps’ design and the way they work mean of unit conveys the product in a way that is particularly gentle on the product. In contrast to the multi screw pump used previously, the progressing cavity pumps work at a low speed which does not affect the quality of the chili and tomato sauce.

Chilli and tomato sauce: Change the pump and save energy

To achieve overall high delivery pressures and thus an efficient pumping process of the chilli and tomato sauce, the two progressing cavity pumps were connected in series. This configuration was necessary because the design of the pasteurisation system resulted in pressure losses of 35 to 40 bar. "Due to the heat exchanger and the holding distance, pressure losses accumulate", explains Rainer Gozzer, business field manager for food & pharmaceuticals at NETZSCH. "If these are distributed over two pumps, it is avoided that the product is subjected to too high mechanical loads."

Both progressing cavity pumps were connected in series to achieve high conveying pressures overall and thus an efficient pumping process. This configuration was necessary because there are pressure losses of 35 to 40 bar due to the design of the pasteurization system. “The heat exchanger and the heat retention section mean that pressure losses accumulate”, said business field manager foods and pharmaceuticals Rainer Gozzer. “Spreading these across two pumps enables us to avoid exposing the product to mechanical stresses that are too high.” This means smooth handling of the sauces is ensured during pasteurization. The NETZSCH progressing cavity pumps which are used have a CIP system. The elastomer materials are manufactured and comply the requirements with the FDA (Food and Drug Administration) and Regulation (EG) Nr. 1935/2004. Both NEMO® progressing cavity pumps have been successfully employed by the food manufacturer since July 2015 and have been running smoothly and quietly. They reliable achieve the desired flow rate, although the food manufacturer has been able to reduce the energy consumption due to the technology change. Since then the manufacturer has no longer been able to detect any damage to the product structure during conveyance.

NEMO® SA aseptic pump with bearing housing

- Medium: Chili and tomato sauce

- Throughput volume: 2 m³/h

- Temperature: 60 to 100 °C

- Pressure: 35 to 40 bar