NETZSCHicon

Abrasion

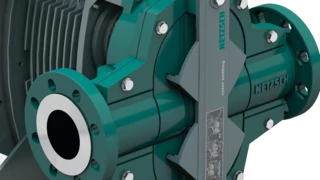

Abrasion occurs in various applications, such as pumps that convey fluids containing solids. These solids lead to wear phenomena, such as scoring and micro-chipping, on the materials' surfaces. Abrasion thus represents a particular form of wear.

The intensity of this mechanical degradation on a surface depends on various factors, including the size and sharpness of the solids, the ratio of hardness to density, and the concentration of the solids in the medium. The resistance to abrasion of different materials can be determined through the coupling insert of a standard test method, the Taber abrasion test. This test helps to quantify the loss of material due to abrasive influences. Abrasive wear leads to a loss of material, shortening the pump's service life and other components that come into contact with the pumped medium. There are various measures to extend the service life of these components and reduce wear. For example, solids concentrations and flow rates are often limited in centrifugal pumps. In addition, the coupling insert of wear-resistant, hard materials and the application of speed controls on the pump can help slow down material loss due to abrasive wear.