18.09.2023

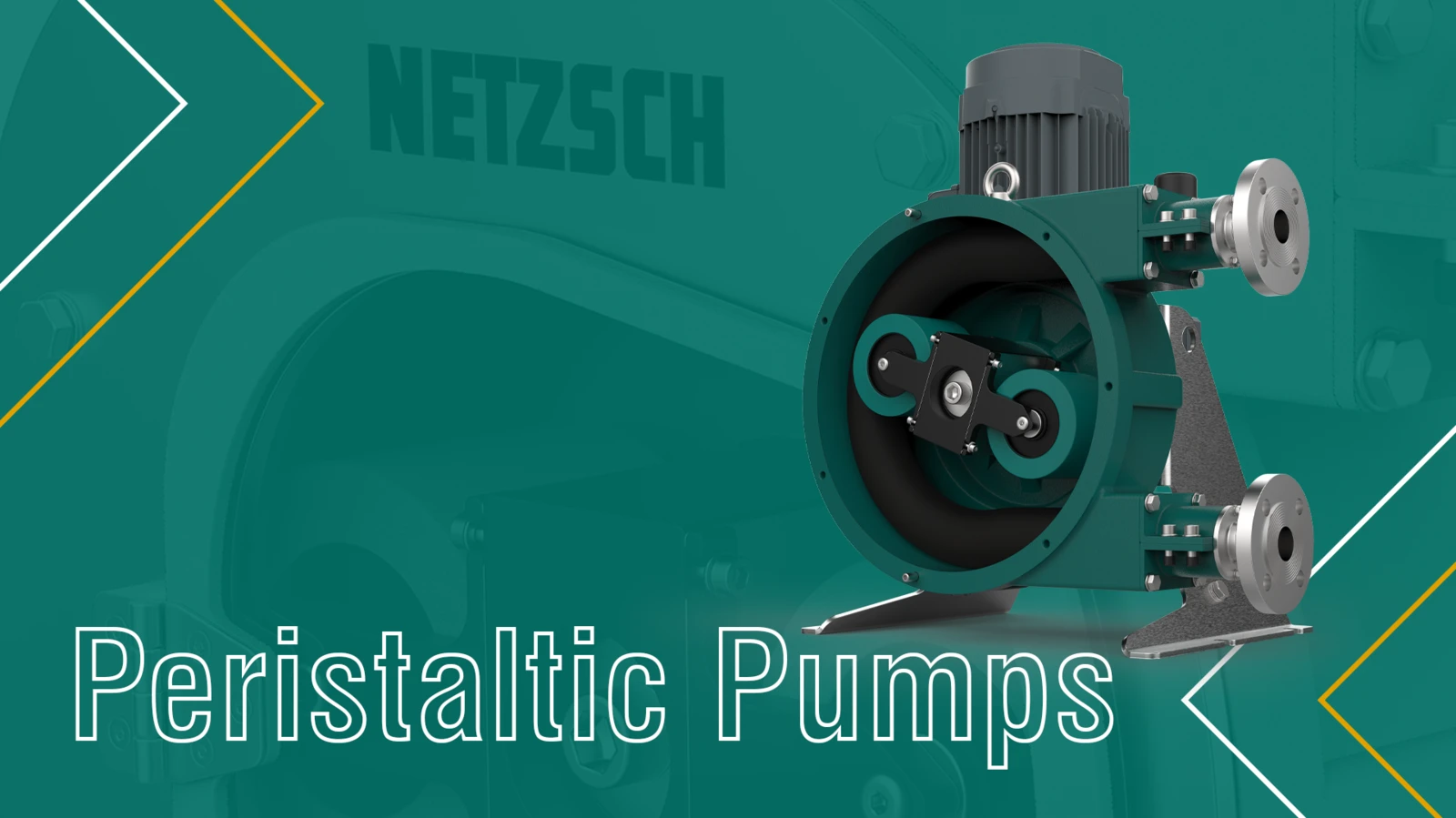

Peristaltic Pumps: Overview of the Highlights

What are peristaltic pumps? How is a peristaltic pump constructed? How does a peristaltic pump work? What are the advantages of peristaltic pumps? In which applications are peristaltic pumps used? There are endless questions, and we have the answers for you.

As a global specialist in handling complex media, NETZSCH Pumps & Systems portfolio includes multi screw pumps in addition to progressing cavity pumps, rotary lobe pumps and peristaltic pumps. Everything you need to know about peristaltic pumps and how to benefit from their use can be found here.

Customised Consulting

What are peristaltic pumps?

A peristaltic pump is another term for a hose pump, squeeze pump or roller pump. Peristaltic pumps, along with all other pump technologies from NETZSCH, belong to the family of positive displacement pumps. The name derives from biological peristalsis, a motion of waves that occurs in human body organs, such as the intestines.

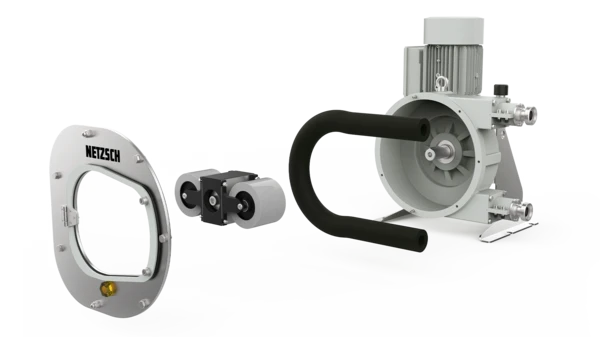

How is a peristaltic pump constructed?

A peristaltic pump consists of several essential components which pump fluid through the tube. First of all, these include the hose, the pump head, the rollers, the drive and the housing. The hose is the central element of peristaltic pumps, conveying the media. It is made of flexible and elastic material, usually silicone, rubber or a similar synthetic material. The pump head is the part of the pump surrounding the hose and containing the rollers. The rollers are mechanical elements which compress the hose to create the peristaltic movement. They are usually mounted on a rotor or rotating shaft. Another important component of peristaltic pumps is the motor. It drives the rotor, which moves the rollers. The housing is also part of the construction of the peristaltic pump. It encloses the pump head, the motor and the drive system. Hence, it provides protection and stability for the internal components.

How does a peristaltic pump work?

The working principle of peristaltic pumps is as simple as their construction. It is based on the rotation of the rollers compressing and releasing the hose. The mechanical deformation of the hose is used to transport the medium through the hose. The hose braces itself against the housing of the pump head and is clamped by the rollers. A rotor moves these rollers, causing the clamping point to move along the hose and pushing the medium forward. The elasticity of the hose material creates the suction pressure. In this way, the fluid is forced through the hose continuously and with low pulsation.

30

What are the advantages of peristaltic pumps?

Peristaltic pumps offer a variety of advantages. A decisive advantage of peristaltic pumps is their low energy consumption. The large rollers reduce your energy consumption by up to 30 percent and significantly extend the life of the hose. Through the compression of the hose by rollers, the friction of a solid shoe is avoided. This results in substantially more efficient pumping. Another advantage is the minimal starting torque occurring when the pump is started. Thus, using a self-priming peristaltic pump reduces energy consumption and saves money. In addition, no supply pump is required, which would consume additional energy. Therefore, the peristaltic pump is a particularly sustainable solution.

As the liquid only comes into contact with the hose, peristaltic pumps deliver particularly gently and without contamination. There are no internal moving parts in contact with the fluid, which counteracts the risk of contamination. In addition, peristaltic pumps are self-priming as they draw liquid into the hose through the vacuum effect. A separate suction line or pre-filling is, therefore, not necessary. Another advantage of peristaltic pumps is that they only contain one wearing part, the hose. Since the hose is easily accessible and replaceable, maintenance work can be done quickly and easily. In addition, peristaltic pumps offer gentle conveying and maximum dosing accuracy. Moreover, peristaltic pumps are insensitive to dry running due to their design. Unlike other technologies, peristaltic pumps do not suffer any damage by pumping air. Since they have no moving parts in the liquid flow and the hose is the only wearing part, peristaltic pumps are easy to maintain and impress with their long service life.

In which applications are peristaltic pumps used?

Due to their advantages, peristaltic pumps are used in various applications and industries. Their ability to convey liquids precisely and gently makes them a popular choice. Especially for pumping complex media, they are ideally suited. When pumping abrasive media such as milk of lime, activated carbon, slurries or similar substances, peristaltic pumps offer you the advantage of fluid contact only with the hose. This minimises wear and, at the same time, increases the service life of your pump. Peristaltic pumps are also an excellent solution for corrosive media such as sodium hypochlorite, ferric chloride, hydrochloric acid and other aggressive chemicals, as the liquid to be pumped has no direct contact with the pump. The hose is a barrier that protects the pump material from corrosion, ensuring long-term and reliable pumping. When pumping viscous media such as adhesives, greases, creams, resins and similar substances, peristaltic pumps allow a smooth and constant liquid flow without clogging or interference. Even highly viscous liquids, pumped materials with a solids content of up to 70 percent or sensitive media such as latex, polymers, flocculants and foodstuffs cause no problems. In summary, peristaltic pumps offer a robust and reliable solution for pumping a wide range of media, including abrasive, corrosive, viscous and sensitive liquids.

Peristaltic pumps from NETZSCH

Robust, reliable, strong: This is precisely what the PERIPRO® peristaltic pumps from NETZSCH stand for. All peristaltic pumps from NETZSCH at a glance:

Whether for industry, chemicals or food, the experts at NETZSCH will find together with you the peristaltic pump optimally matching your application. We promise you Proven Excellence - outstanding performance in all areas.