22.01.2024

Six Questions & Answers About Hose Pumps

Do you want to reduce your lubricant consumption and achieve energy savings? In this case, the hose pump technology is the right one for your application. We have summarised the most important information on hose pumps for you.

Controlled and precise pumping of media with a high solids content plays a central role in numerous industries where accurate dosing, gentle pumping and contamination prevention are paramount. In this context, hose pumps, also known as peristaltic pumps, are becoming increasingly popular. Find out everything you need to know about hose pumps here.

Customised Consulting

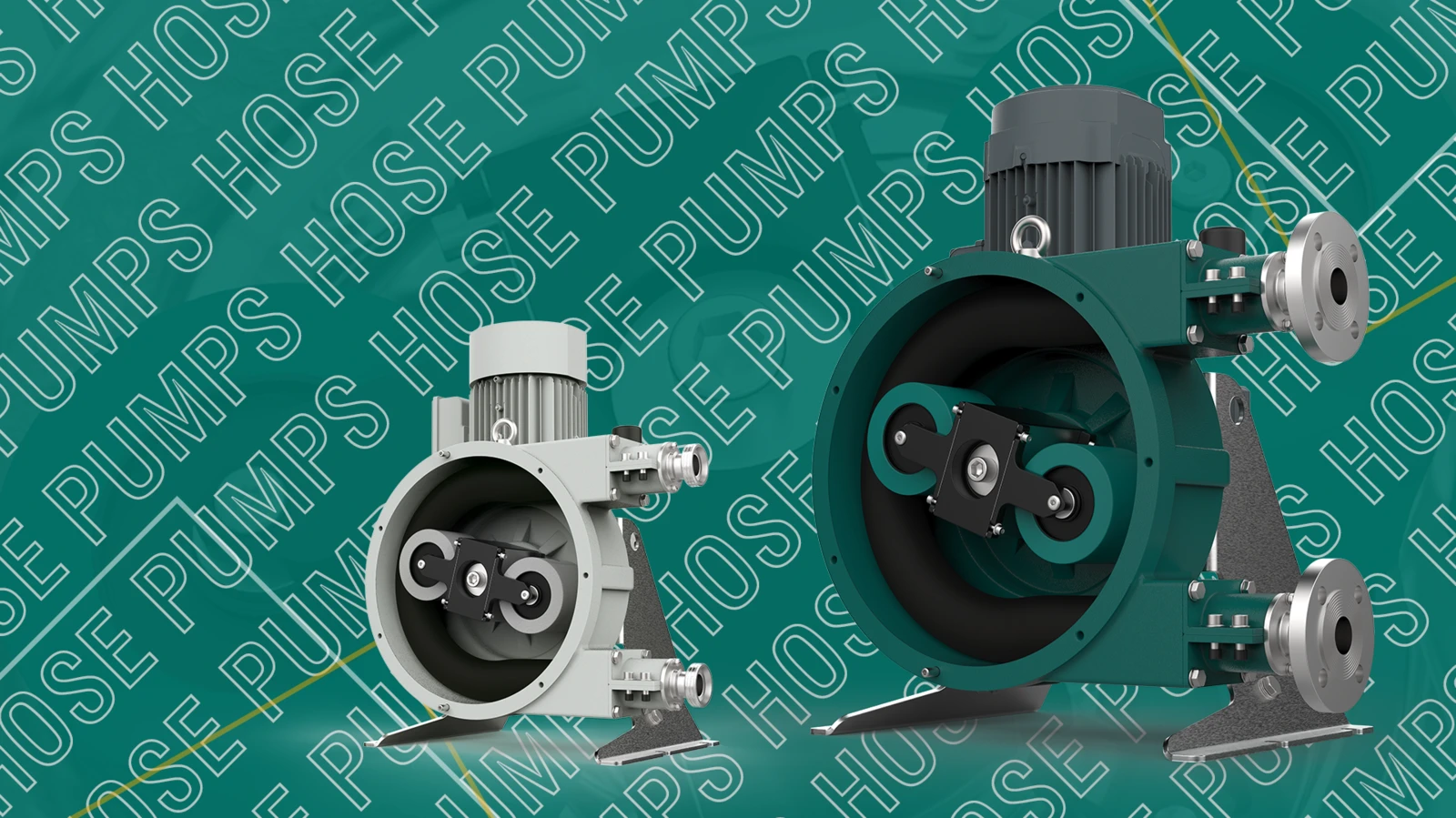

What are hose pumps?

Hose pumps are positive displacement pumps used, among other things, to pump liquids with a high solids content. The basic construction of a hose pump consists of a flexible hose that is squeezed by a rotor or roller mechanism. This squeezing movement transports the liquid forward in the hose. Hose pumps are also known as peristaltic pumps, as the mechanism by which the hose is squeezed is reminiscent of the contraction movements of the muscles in human peristalsis. You can use hose pumps in various industries such as chemicals, food processing, pharmaceuticals and environmental technology. Thereby, you will benefit from gentle conveying and precise dosing.

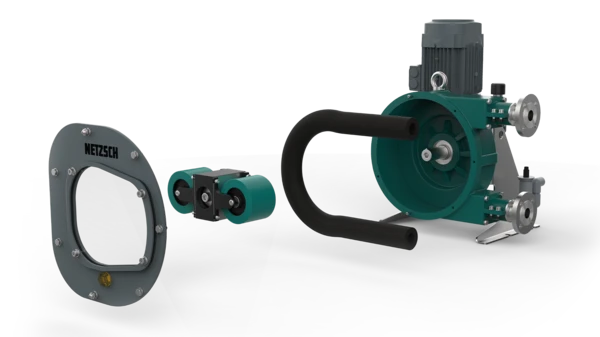

How is a hose pump constructed?

Hose pumps consist of the following main components:

- Flexible hose

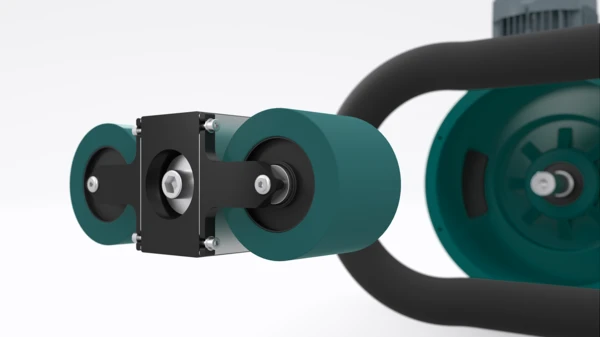

- Rotor or roller mechanism

- Pump housing

- Drive system

- Inlet and outlet connections

The hose is the central element of the hose pump. It is an elastic, flexible hose that is compressed by external pressure and afterwards expands again. The hose can be made of various materials, such as rubber or thermoplastic elastomers. The rotor or roller mechanism is responsible for the squeezing movement of the hose. It can consist of a rotating rotor, a shoe or an arrangement of rollers. This mechanism ensures that the hose is periodically squeezed, causing the liquid to be pumped forward. The pump housing encloses the flexible hose and the rotor or roller mechanism. It protects the components and allows the pressure and flow to be controlled. A motor or drive system is required to move the rotating element. This drive provides the periodic squeezing movement. The hose pump also has inlet and outlet connections through which the medium to be pumped is introduced into the hose and discharged at the other end.

How do hose pumps work?

Hose pumps work on the peristalsis principle. This principle is based on the squeezing movement of a flexible hose, which is periodically compressed by a rotor or roller mechanism. At the beginning of the pumping process, the hose is wholly or partially filled with the liquid to be pumped. The hose can be filled with fluid by gravity or with the help of back suction. As the rotor or rollers of the pump mechanism rotate, they move over the flexible hose. This movement periodically compresses the hose. The squeezing movement of the hose causes the liquid to be pushed forward. The pressure created by the squeezing moves the fluid towards the pump outlet. After the rotor or rollers have passed the hose in a squeezing motion, the hose relaxes again, drawing in liquid for the next pumping cycle. This process is repeated continuously, ensuring the fluid is pumped evenly and with slight pulsation.

What are hose pumps used for?

Hose pumps are used in various branches of industry, especially where precise and gentle pumping of liquids with a high solids content is required. You can use hose pumps in the chemical industry to convey various chemicals safely and precisely. Due to their ability to handle sensitive media, you benefit particularly when dosing chemicals in laboratories and industrial processes. Another area of application for hose pumps is food processing. You can use hose pumps to dose ingredients such as flavourings or colourings in this case. Due to their design, they offer you the highest level of hygiene and avoid contamination. This is why they are often used to dose medicines precisely in pharmaceutical applications. Their ability to deliver continuously and with low pulsation makes them particularly suitable for producing medicines. The requirements in the environmental sector are completely different. Due to their robust design, hose pumps are ideal for sampling water, adding chemicals for water treatment, or pumping sludge and wastewater. You can also use hose pumps for dosing chemicals in water and wastewater treatment plants to adjust pH values or add disinfectants. In laboratories, analytical instruments such as chromatographs often use hose pumps to dose solvents or reagents precisely. Here, you benefit from the high dosing accuracy. The deviation is less than one percent.

What are the advantages of hose pumps?

In addition to their versatility, hose pumps offer a range of advantages. They pump liquids very gently, as the fluid only comes into contact with the flexible hose. This makes them particularly suitable for sensitive media, such as in the pharmaceutical or biotechnology industries. Using hose pumps, you also benefit from the fact that they are self-priming and insensitive to dry running. This is particularly useful in applications where the pump is not constantly filled with liquid. The squeezing mechanism of the hose pump generates a uniform and pulsation-free flow. This enables a constant fluid flow, as required in analytical chemistry. Another decisive advantage of hose pumps is that the hose is the only wearing part. This simplifies maintenance and cleaning enormously for you. The hose can be replaced quickly and easily without dismantling the entire pump. This minimises your downtime and service times while saving you money simultaneously. Furthermore, using peristaltic pumps minimises the risk of contamination from other pump components, as the liquid to be pumped only comes into contact with the hose. Due to the closed system and limited moving parts, there is also a lower risk of leaks than other pump types. Another advantage of hose pumps is high capacity. The robust design of hose pumps makes them suitable for pumping even abrasive and aggressive media such as sludge, ceramic slurry or mortar. Another decisive advantage of hose pumps is their low energy consumption. The large rollers reduce your energy consumption by up to 30 percent and ensure a long service life for the hose. All in all, these advantages make hose pumps an attractive option in many industrial applications.

Low energy consumption

High dosing accuracy

High solid content

Where to buy hose pumps?

One of the premium suppliers of hose pumps on a global scale is NETZSCH Pumps & Systems. NETZSCH has been developing, producing and distributing positive displacement pumps worldwide for over 70 years. The particularly robust and maintenance-friendly PERIPRO® hose pumps from NETZSCH are suitable for aggressive and abrasive media with a solids content of up to 70 percent. At the same time, they offer you an extremely high suction capacity with minimal maintenance requirements. We promise you Proven Excellence - outstanding performance in all areas.

You're wondering whether the hose pump technology is the right one for your application? No problem! We will collaborate with you to find the right pump solution for your problem. As a global specialist in handling complex media, NETZSCH offers you numerous other technologies such as progressing cavity pumps, rotary lobe pumps, multi screw pumps, barrel emptying and grinding systems - you got the application, we provide the solution!