APPLICATIONS & SOLUTIONS

NETZSCH Pump Solutions in the Oil and Gas Upstream Sector

We find and develop the perfect positive displacement pump for your individual application

Special challenges require innovative and customised solutions. As the world's leading supplier of positive displacement pumps, NETZSCH offers you pumps and systems individually adapted to your requirements in the oil and gas upstream sector on a global level.

Together with you, we find and develop the optimal pump solution for your application. The satisfaction of our customers is always our top priority at NETZSCH. Whether you are a large oilfield operator or a small production company, we dedicate ourselves to your projects with the highest passion.

We promise you Proven Excellence – outstanding performance in all areas. To meet the increasing technological requirements, we are continuously researching innovative solutions together with universities and operators of our pumps.

Individual Consulting

Opportunities for efficient production in the oil and gas upstream sector

Our innovative pumps for the oil industry are characterised by a robust and reliable design. Together with you, we define the requirements in the planning phase and thus globally find the pumps and systems optimally matched to your application.

„Oil and gas are among the world's most important energy suppliers. Although new deposits are still being discovered, already preceded oil fields continue being serviced, the production of this viscous solids-containing raw material is becoming more complex. By using NETZSCH-Drive Heads and the progressing cavity pump-systems, many of these reserves can be explored and used efficiently.“

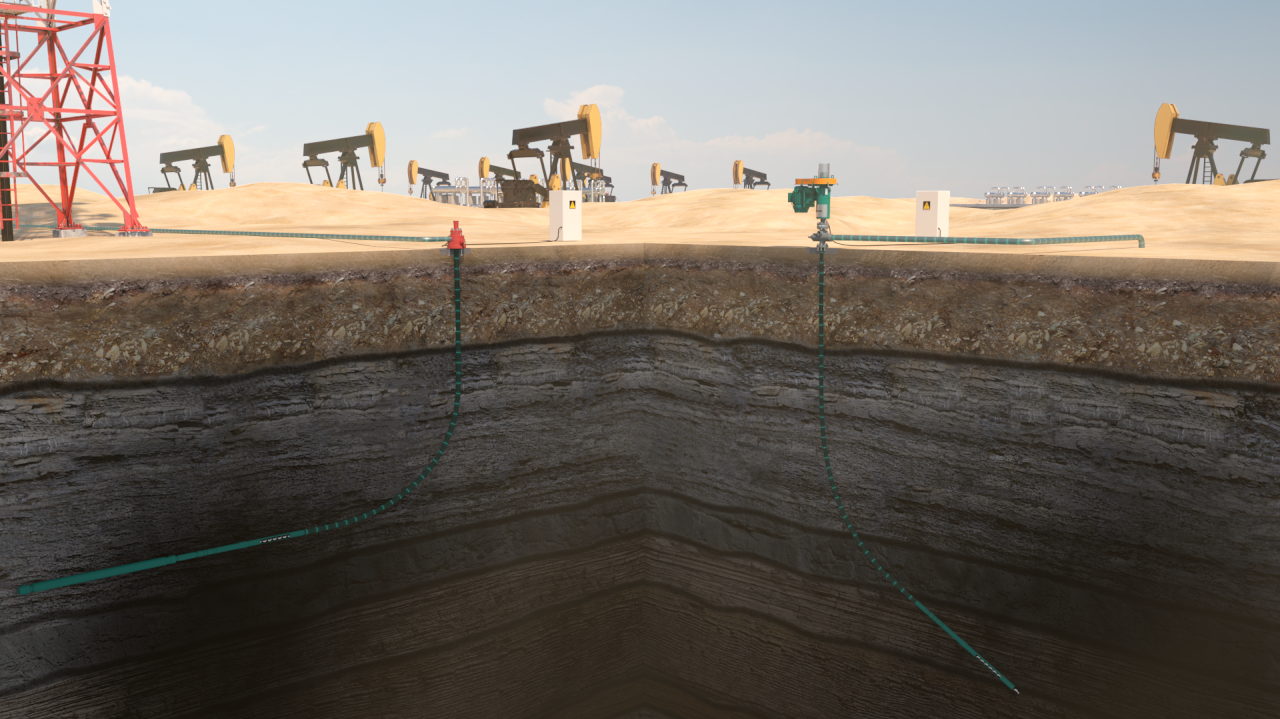

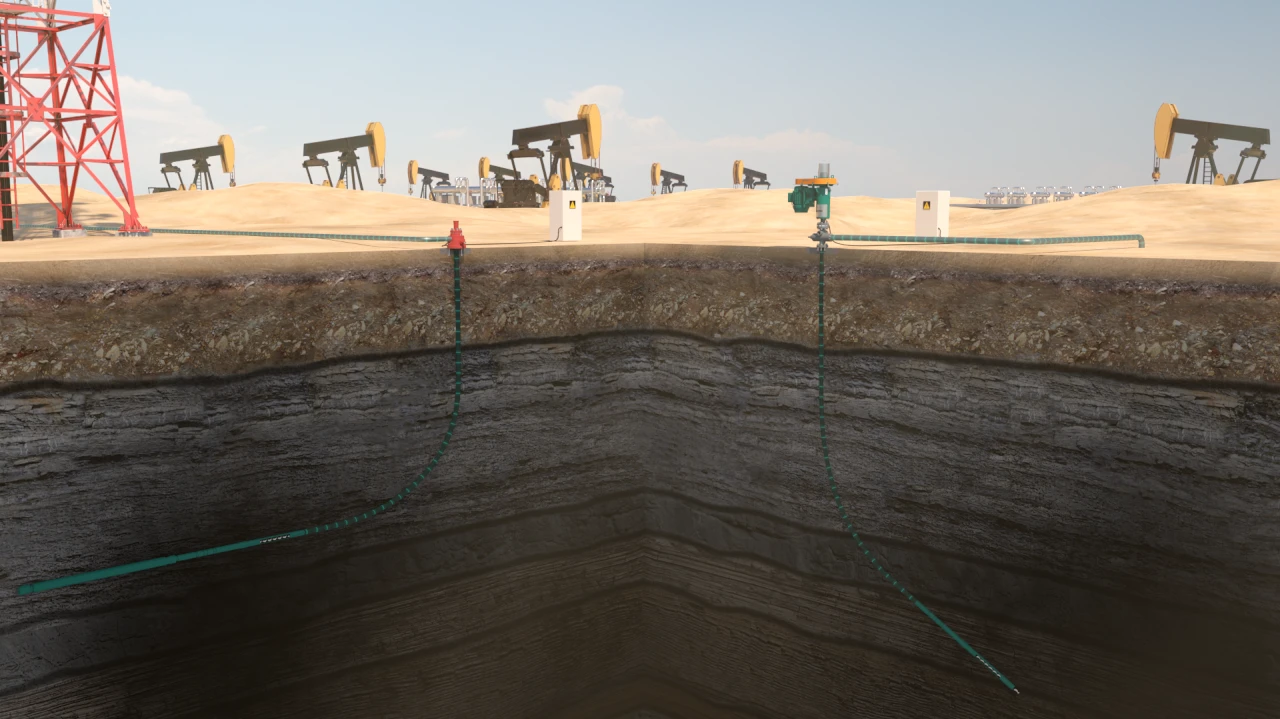

Efficient conveying of diluted oil fields with high gas content

Do you want to increase the efficiency when pumping an oil-water mixture? The specially designed, underground-driven progressing cavity pumps make it possible. At the same time, you reduce your costs as well as the consumption of resources. Even changing pumping conditions, including a high free gas content, pose no problems for the underground-driven progressing cavity pump. As a result, you can pump efficiently from even heavily diluted oil fields.

High-tech solutions for efficient production in oil and gas fields

Oil production 4.0 - Digitalisation is also changing the pump industry more and more. Thanks to the complete downhole sensor system, you can pump particularly efficiently even under challenging conditions with our high-tech pump solutions. In addition to pressure, temperature and vibration sensors, the sensor technology provides data on the pressure at the pump, from which you can conclude the dynamic level of the fluid in the borehole. This allows you to detect possible faults at an early stage and prevent damage to the pump. In addition, thanks to the digitalisation of oil and gas fields, you optimise your efficiency in crude oil production.

Crude oil production under the most difficult external conditions

The location of the oil fields is as varied as their quality. Even strongly changing temperatures, such as in deserts, do not pose a problem for the downhole progressing cavity pumps. Despite the challenges, the innovative progressing cavity pumps with drive heads impress with long service life and long maintenance intervals. This keeps your life cycle costs low, which ensures profitability even with lower quality crude oil.

Permanent monitoring of the dynamic fluid level

The conditions underground are constantly changing. With our underground driven progressing cavity pumps, you monitor the dynamic fluid level and frequently adjust the operating conditions thanks to the unique frequency control. This increases efficiency, and you achieve a significant reduction in energy consumption. At the same time, thanks to the special design, environmental pollution caused by leaks above ground is ruled out.

Environmentally and climate-friendly crude oil production

Environmental and climate protection play a central role at NETZSCH. In contrast to the use of conventional horse-head pumps, both the pumping elements and the motor are located in the borehole in the case of NETZSCH's underground-driven progressing cavity pumps. This means that you rule out environmental pollution due to leakage above ground.

Conveying the most challenging media in oil and gas fields

Oil-sand mixtures pose problems for many pumps in crude oil production. With the unique progressing cavity oil pumps, you can efficiently convey even the most challenging media without damaging the product. By avoiding pulsation and shear forces, you prevent possible emulsion effects. This makes it much easier for you to separate the mixtures at the surface. At the same time, they increase your efficiency by up to 60 percent, thanks to the innovative design.