APPLICATIONS & SOLUTIONS

NETZSCH Pump Solutions in the Food and Pharmaceutical Sectors

We find and develop the perfect positive displacement pump for your individual application

As the world's leading supplier in the field of positive displacement pumps, NETZSCH offers you an individual and innovative solution in the areas of food and pharmaceuticals. With our pumps and systems, you can convey your products gently and cleanly in compliance with all hygiene guidelines.

Due to the wide variety of applications in the food and pharmaceutical sectors, we develop customised and sophisticated pump solutions for your request on a global level. We promise you Proven Excellence – outstanding performance in all areas. Whether in the beverage industry, in the production of foodstuffs, for pumping cosmetics or pharmaceutical products, in dairy operations or for conveying oils and fats, the satisfaction of our customers is always our top priority.

Whether in the beverage industry, in the production of foodstuffs, for pumping cosmetics or pharmaceutical products, in dairy operations or for conveying oils and fats, the satisfaction of our customers is always our top priority.

Individual Consulting

Special challenge: High hygienic standards

To be approved for use in the food and pharmaceutical industries, pumps from NETZSCH are subject to a whole range of hygienic guidelines, from the EHEDG to the 3-A Sanitary Standard to specifications from the US Food and Drug Administration (FDA). Our pumps and systems open up new possibilities for you and your manufacturing processes.

„In food processing, the production of cosmetics and the pharmaceutical industry in particular, we have to take special care with regard to the consumer. This of course means that all NEMO® and TORNADO® pumps are made according to the nationally and internationally relevant manufacturing and hygiene standards and guidelines.“

Hygienic pumping of liquids and emptying of barrels

In the food and beverage industry, gentle pumping and compliance with hygiene standards play a crucial role. With the oil-free TORNADO® T.Sano® rotary lobe pump, you can dose even sparkling and semi-sparkling wines extremely precisely and gently at the same time. Since pumping is based on the positive displacement pump principle, pressure fluctuations or shear forces are ruled out. This prevents unwanted foam formation. Thanks to our unique barrel emptying systems, barrels' almost residue-free and hygienic emptying are also no problem. If space is limited, a closed system with a TORNADO® T.Sano® rotary lobe pump is also suitable for emptying. Thanks to the innovative design, you can convey products in a soup kitchen, for example, under the highest hygiene standards.

Efficient and temperature-controlled conveying of critical media

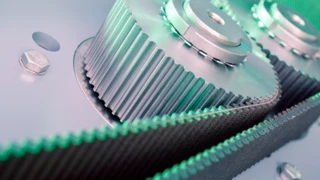

The pumping of edible oils and fats entails a wide variety of requirements. In addition to the high hygienic conditions, the TORNADO® T.Sano® rotary lobe pump offers you meagre maintenance costs. In addition, the rotary lobe pump ensures gentle and efficient pumping. This makes it suitable even for the production of products such as mayonnaise. Thanks to the innovative design and the unique belt drive, the rotary lobe pump gives you the maximum flexibility in every application situation. If required, the T.Sano® can be mounted on a mobile stand.

Hygienic, flexible and gentle transport of edible oils and fats

The pumping of edible oils and fats entails a wide variety of requirements. In addition to the high hygienic conditions, the TORNADO® T.Sano® rotary lobe pump offers you meagre maintenance costs. In addition, the rotary lobe pump ensures gentle and efficient pumping. This makes it suitable even for the production of products such as mayonnaise. Thanks to the innovative design and the unique belt drive, the rotary lobe pump gives you the maximum flexibility in every application situation. If required, the T.Sano® can be mounted on a mobile stand.

Hygienic and reliable conveying in dairies

Particularly demanding media such as yoghurt, milk, condensed milk or other dairy products require extremely gentle conveying in compliance with the strictest hygiene standards. With the NEMO® progressing cavity pump, you can transport even the most demanding products without wear and lubrication. This enables you to convey aseptic products and it protects your product from contamination. Thanks to the dead space-free design, the progressing cavity pump can be cleaned without being removed from the system. This saves you considerable time and costs during servicing.

Increased efficiency and hygiene when pumping pharmaceutical products

The pumping of pharmaceutical media such as cell mass and suspension, for example in insulin production, requires the highest efficiency and hygiene. Due to the special design of the NEMO® progressing cavity pump without dead space and the optimal cleanability, the pump fulfils even the strictest hygiene guidelines. In addition, the progressing cavity pump offers you long maintenance intervals. The residue-free cleanability in the system and the long service intervals increase your productivity.