APPLICATIONS & SOLUTIONS

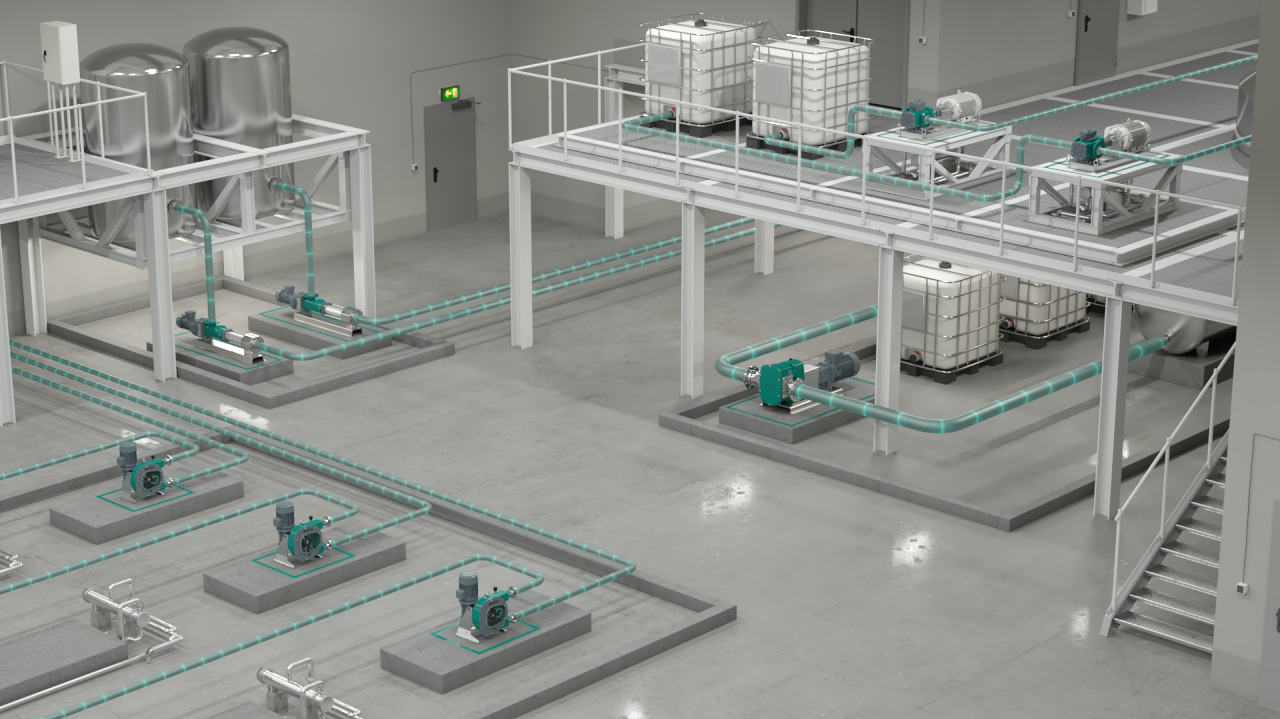

NETZSCH Pump Solutions in the Chemical, Pulp and Paper Industries

We find and develop the perfect positive displacement pump for your individual application

As a worldwide leading supplier of positive displacement pumps, NETZSCH offers you individually optimised pump solutions in the areas of chemicals, pulp and paper. With our pumps and systems, you can safely convey even the most challenging media.

We globally develop customised and sophisticated solutions for you in the chemical, pulp and paper sectors. Fluids that are hazardous to health and the environment, highly viscous products, products containing solids or sensitive products require pumps that can handle even the most challenging media in hermetically isolated systems.

We make no compromises when it comes to your safety. In any case, the satisfaction of our customers is always our top priority. Together with you, we will find the product optimally tailored to you and your requirements.

Individual Consulting

Find the right pump for your chemical, pulp and paper application

We promise you Proven Excellence – outstanding performance in all areas. NETZSCH rotary lobe pumps, progressing cavity pumps, and multi screw pumps, combined with our grinders, constantly guarantee you the right solution for your process. Together with you, we will find the product optimally tailored to you and your requirements.

„We offer our customers professional advice in a variety of applications in the chemical and process industries, even in highly specialized industries such as mining and explosives industry, in the choice of the optimal pump.“

Continuous conveying of abrasive and corrosive paints and varnishes

With NEMO® progressing cavity pumps, you can continuously convey even abrasive and corrosive media in the paint and paper industry. In addition, the progressing cavity pump enables you to achieve exact dosing despite a lack of fluidity. Thanks to the innovative design of the NEMO®, maintenance and service can be carried out even when the pump is installed. This saves you time and the associated maintenance costs. The TORNADO® T.Proc® rotary lobe pump has a particularly long service life when pumping abrasive media in the construction industry. You can even pump dispersion-containing primers with a high solids content without any problems. In this way, you extend the service life by more than three times.

Exact mixing and dosing of different material components in silicone production

Precise dosing plays a decisive role with modern materials. With the NEMO®barrel emptying systems, you can dose a wide variety of material components without interruption. This is made possible by the unique design of the progressing cavity pump. NEMO® barrel emptying systems guarantee you precision requirements of plus or minus one percent. Thanks to the high delivery volume and the uninterrupted dosing, you can significantly reduce your processing time.

Fast and reliable conveying in paper and pulp processing

With TORNADO® rotary lobe pumps, you can convey media with special requirements such as kaolin slurry or ceramic slurry quickly and reliably. Thanks to an individual material pairing optimally matched to the product, the TORNADO® enables you to achieve particularly long running times with low maintenance. To save time when cleaning and maintenance work is required, you can remove the front of the pump chamber in a few easy steps. This makes the entire pumping area easily accessible. Thus you can shorten your service times, which is a great advantage, especially with abrasive and highly viscous products.

Safe, gentle and efficient conveying of highly reactive substances

Substances such as lithium sludge are among the most demanding pumped media. The NEMO® progressing cavity pumps in stainless steel design enable you to pump highly reactive substances efficiently. Thanks to the innovative design, you pump the medium continuously and gently, i.e. free of pressure fluctuations, pulsation or shear forces. This keeps maintenance and servicing costs extremely low, even with demanding media.

Uninterrupted and safe discharge of numerous types of hazardous substances

The pumping of fatty acids in the chemical industry is subject to stringent legal requirements. With the innovative TORNADO® T.Proc® rotary lobe pumps, you can pump the most diverse types of hazardous substances in compliance with all regulations. The unique design enables you to safely empty and fill tanks or tank trucks and ensures a particularly long service life. Even solvent-contaminated media pose no problems for the TORNADO®. This means that you expose neither personnel, consumers, nor the environment to unnecessary danger.