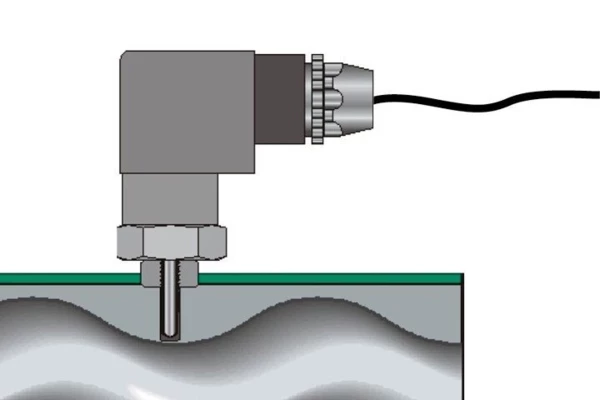

Dry Running Protection for NEMOLAST® Stators

The dry running protection units (STP2A) continually monitor the surface temperature of the stator during operation. Should the operating temperature rise over a predetermined set point due to an increase in friction caused by dry running, a signal is sent to the motor control unit and the pump shuts down. This prevents any damage to stator and rotor. The controller can be set for two different switch-off temperatures: the first set temperature would be for the normally pumped product, the second set temperature for a different substance temperature, for example during a cleaning process.

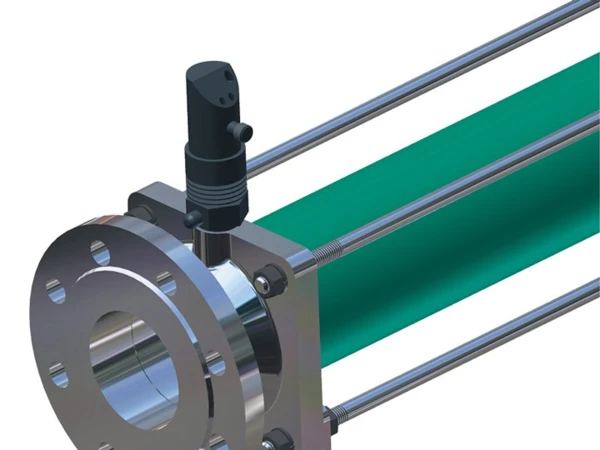

Flow Sensing Unit for Solid Stators

The flow sensing unit is used to protect a pump fitted with a solid stator against dry running. The unit is installed in close proximity to the pump itself, either in the suction or in the discharge pipework. Should the flow drop below a certain level, indicating a dry running situation, a signal is sent to the motor control unit and the pump shuts down, thus preventing any damage.

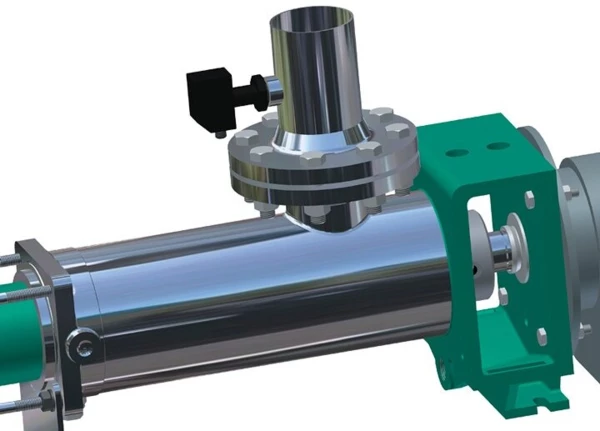

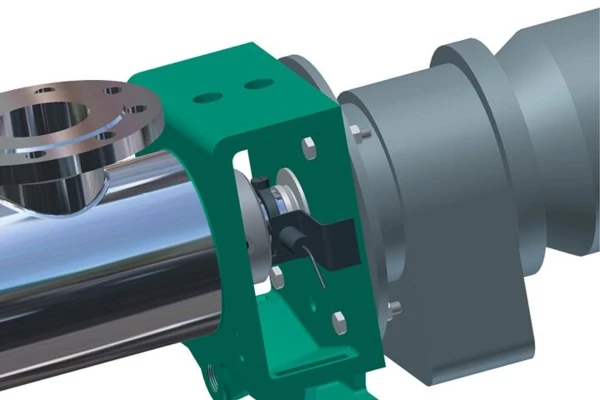

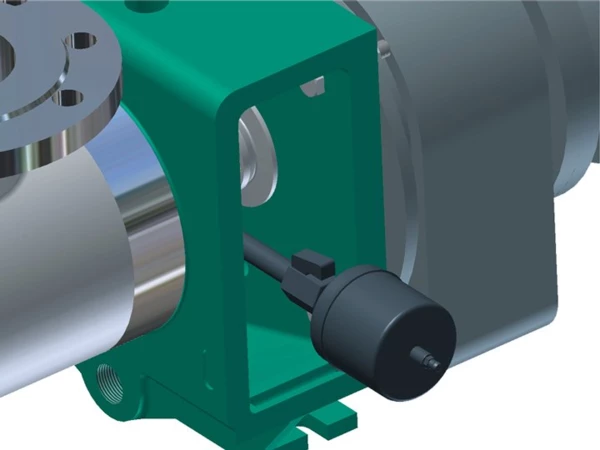

Speed Monitoring Device

Some processes require that the rotational speed of the pump be monitored. Where this is necessary, NETZSCH offers impulse switches mounted to the drive unit. The shaft can be fitted with one or more contacts to measure the required number of impulses per revolution. These units can be fitted to both block construction and bearing housing pump designs and are supplied securely mounted to the lantern or the bearing block.

Diaphragm Pressure Gauge, G3/4 Inch Connection

The operating pressure is displayed by means of a pressure gauge. This gauge is isolated from the process fluid by a stainless steel diaphragm. The G3/4 inch gauge is suitable for use with substances of low to medium viscosity. The pump shuts down automatically when the maximum allowable pressure is exceeded; this cut-out pressure is adjustable.

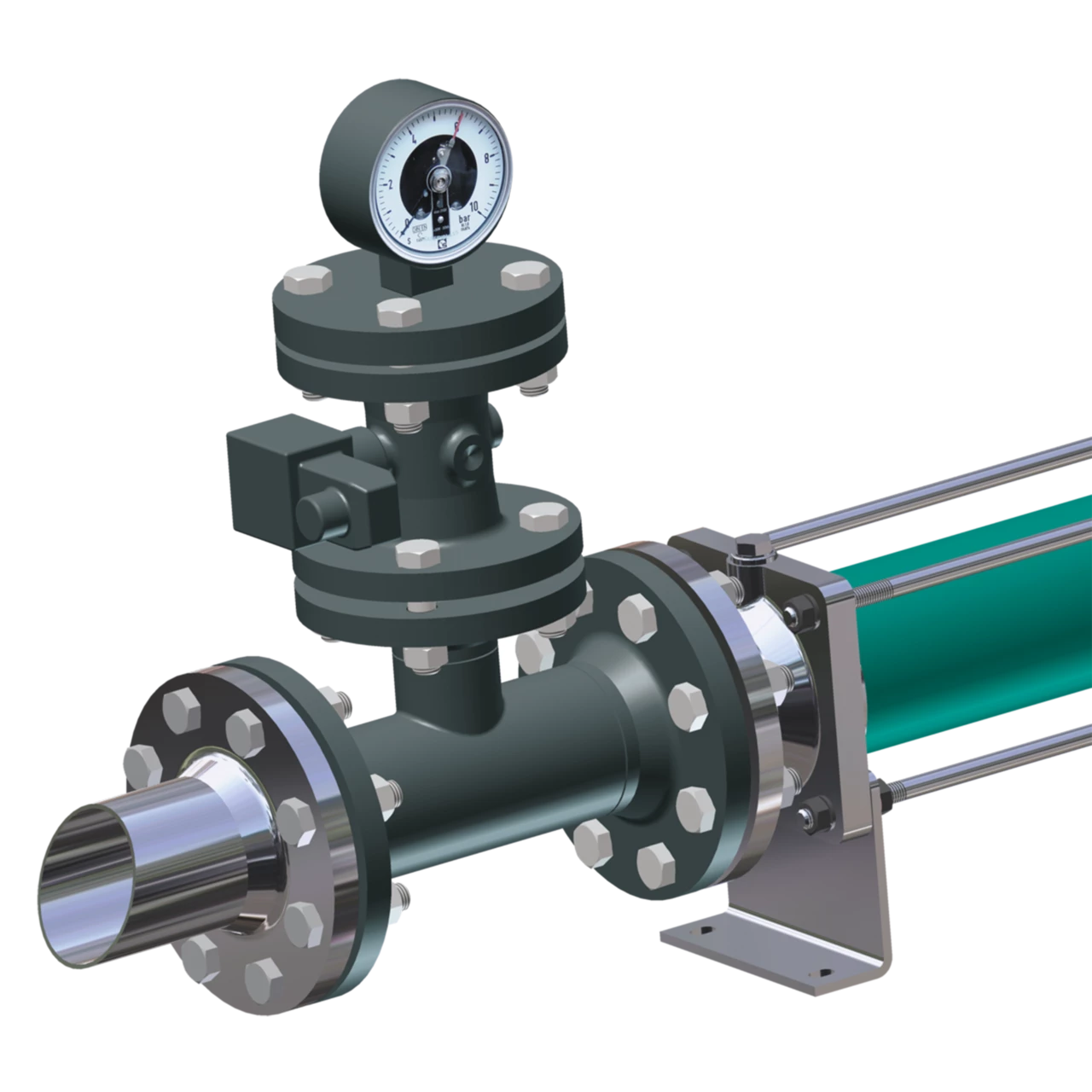

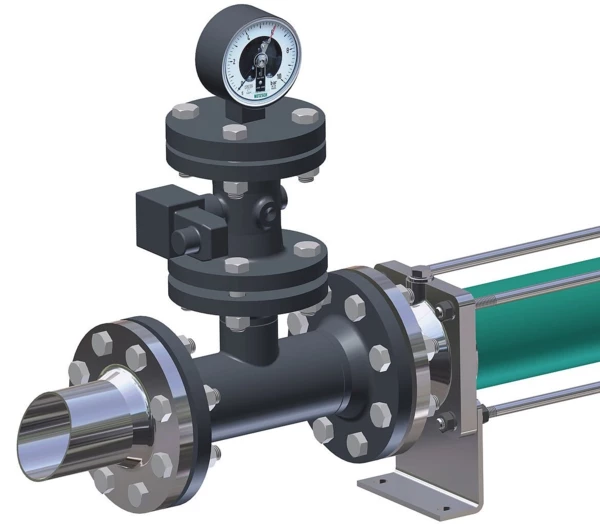

Diaphragm Pressure Gauge with DN50/PN40 or 2” ANSI B16.5 330 lbs. Flanged Connection

This pressure gauge differs from the G3/4 inch by means of the DN50 open measuring flange. The large nominal width of the measuring flange enables dependable protection against overpressure even for highly viscous and clogging substances.

Pressure Control Device DTSL 3

The operating pressure is displayed by a Bourdon gauge which is securely isolated from the process fluid by means of an elastic diaphragm. The pump shuts down automatically when the maximum allowable pressure is exceeded; this cut-out pressure is adjustable. The Pressure Control Device is also optionally available with a differential pressure on/off switch.

Multi-Function Pressure Instrument

In addition to a display indicating the current operating pressure of the pump, this easy-to-install unit also allows the setting of additional points for alarm or emergency shut-down due to overpressure.

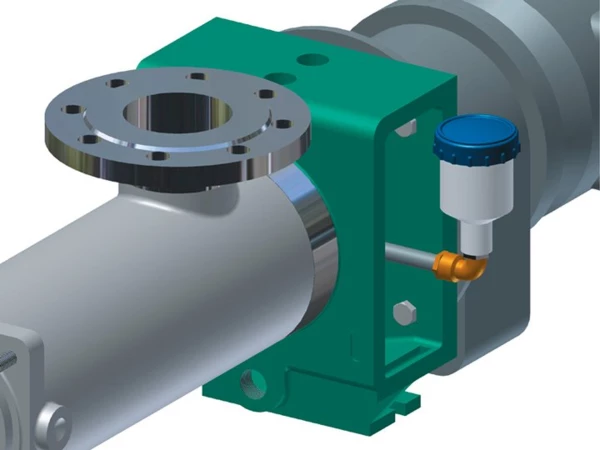

Permanent Lubricator

The Permanent Lubricator is used to support the sealing function of the shaft seal. It can be used for packed glands as well as mechanical seals fitted with an additional quench ring. The function of the Permanent Lubricator is to continually keep grease in the grease chamber ring or quench pot under pressure by means of a pre-stressed spring. A shut-off device on the lubricator can be activated to accommodate periods when the pump is idle.

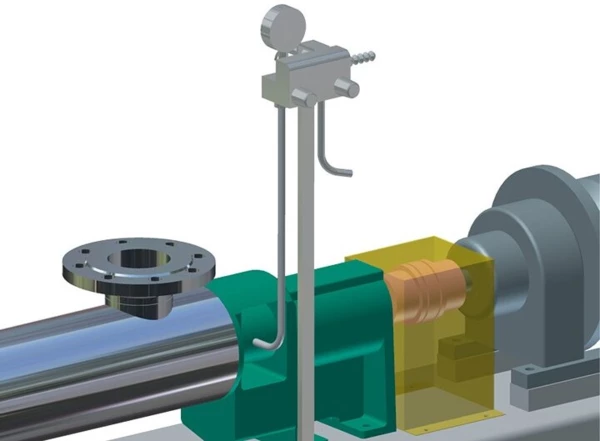

Pressurized Flushing for Double Mechanical Seal Systems

When using a back-to-back mechanical seal, it is necessary to provide a sealing water supply unit for the seal. For such a system to operate correctly, the sealing pressure applied to the mechanical seal must be at least 2 bar above the pressure prevailing in the suction housing. Furthermore, it is necessary to be able to control the volume of flow in the seal chamber. The pressure and flow monitoring system is mounted onto the pump.

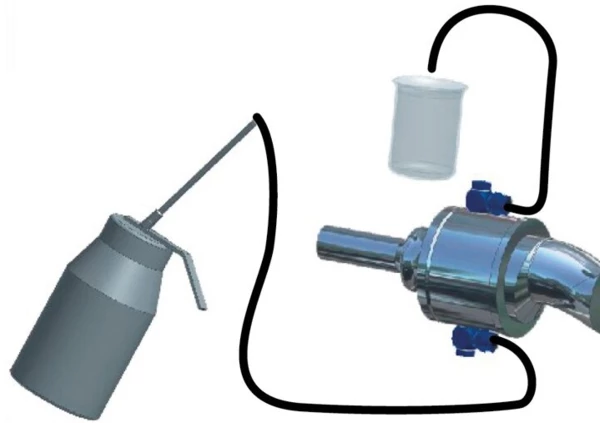

Gear Joint Filling Unit

For the correct operation of a gear joint and to ensure a long service life, these joints must be correctly filled with the lubricating oil specified by NETZSCH in the operating and maintenance manual. A quick and complete filling can only be guaranteed if a Gear Joint Filling Unit complete with oil container, pump unit and hoses is used.

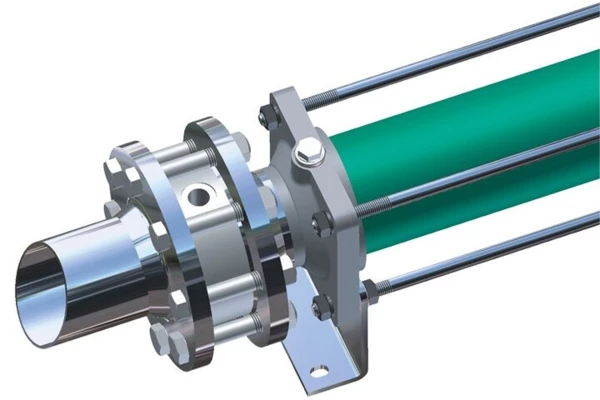

Ring Dosing Nozzle

When conveying high viscosity media, we recommend the installation of our ring dosing nozzle to reduce pressure loss in the pipeline. The nozzle fits directly behind the pressure joint of the pump. Depending on the lubricant used, the discharge pressure can be reduced by up to 70% as a result of frictional loss. By operating this system, both the investment and operating costs are significantly reduced.

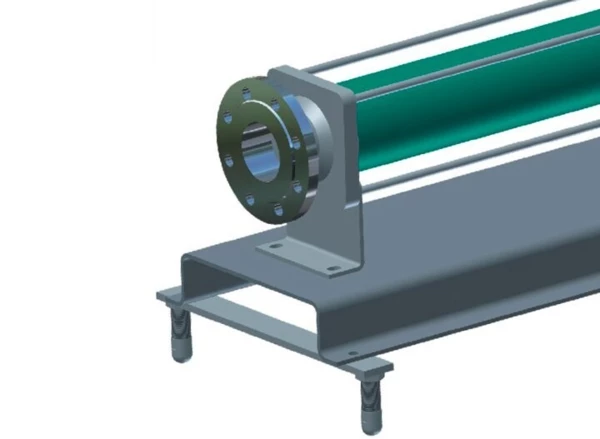

Chemical Anchors

To fix pump baseplates to the ground securely, we recommend the use of our chemical anchoring system. A two-component adhesive is used to secure the anchor to the floor. After a short curing time, the anchor is fixed to the ground, allowing subsequent mounting of the baseplate and the pump.

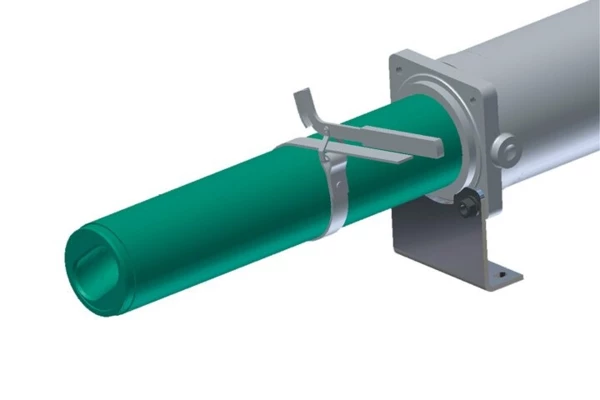

Stator Removal Tool

This tool aids in the removal and mounting of stators. For pump sizes up to NM 045, we recommend the use of our strap wrench. For the pump sizes from NM 053 upward, our chain wrench is recommended.

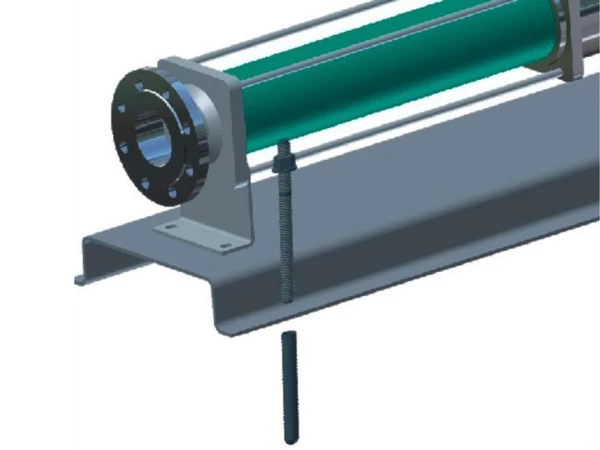

Machine Feet

Often when installing a pump together with a baseplate, it is necessary to ensure that the floor surface not be damaged. To protect flooring, machine feet are mounted directly to the baseplate; floor tiles are thereby not damaged as they would be with fixed anchoring. Another important advantage involves hygiene: no crevices or hollow areas exist where bacteria can accumulate, and it is easy to clean the floor under the baseplate. Also, the stainless steel threaded spindle evens out any irregularities in the floor surface.

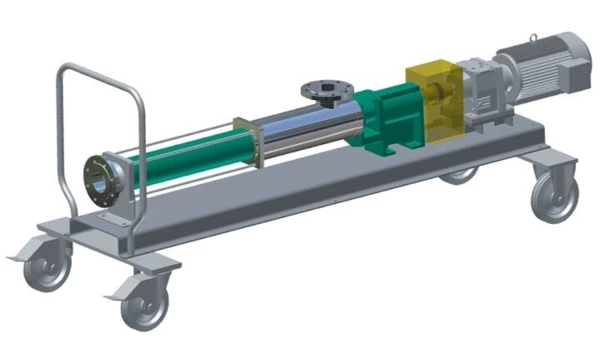

Trolley Assemblies

Sometimes the same pump needs to be used at various locations. We offer a great variety of trolley assemblies to help you with the transport.

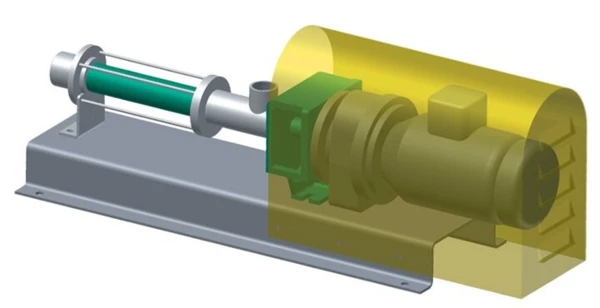

Covers for Drive Monitors

For pumps that require an additional level of protection, we offer a range of stainless steel covers for the drive. These are especially practical for units operated in a wet environment as they provide protection against spraying and condensation. Other examples of reasons to use a drive cover include protection against contact with hot drives, weather protection for drives installed in an open air environment, covering of the rotating drive shaft in the pump lantern, or simply for optical reasons.