20.05.2024

How to Benefit From Multi Screw Pumps in Demanding Industries

Maximum performance and efficiency in demanding industries: Multi screw pumps are an optimal solution for a wide range of industries and enable you to pump even complex media efficiently and reliably.

The multi screw pumps technology offers you several advantages, making it the optimal choice for demanding industrial applications. We will show you the advantages and how to benefit.

Customised Consulting

Increasing efficiency with multi screw pumps

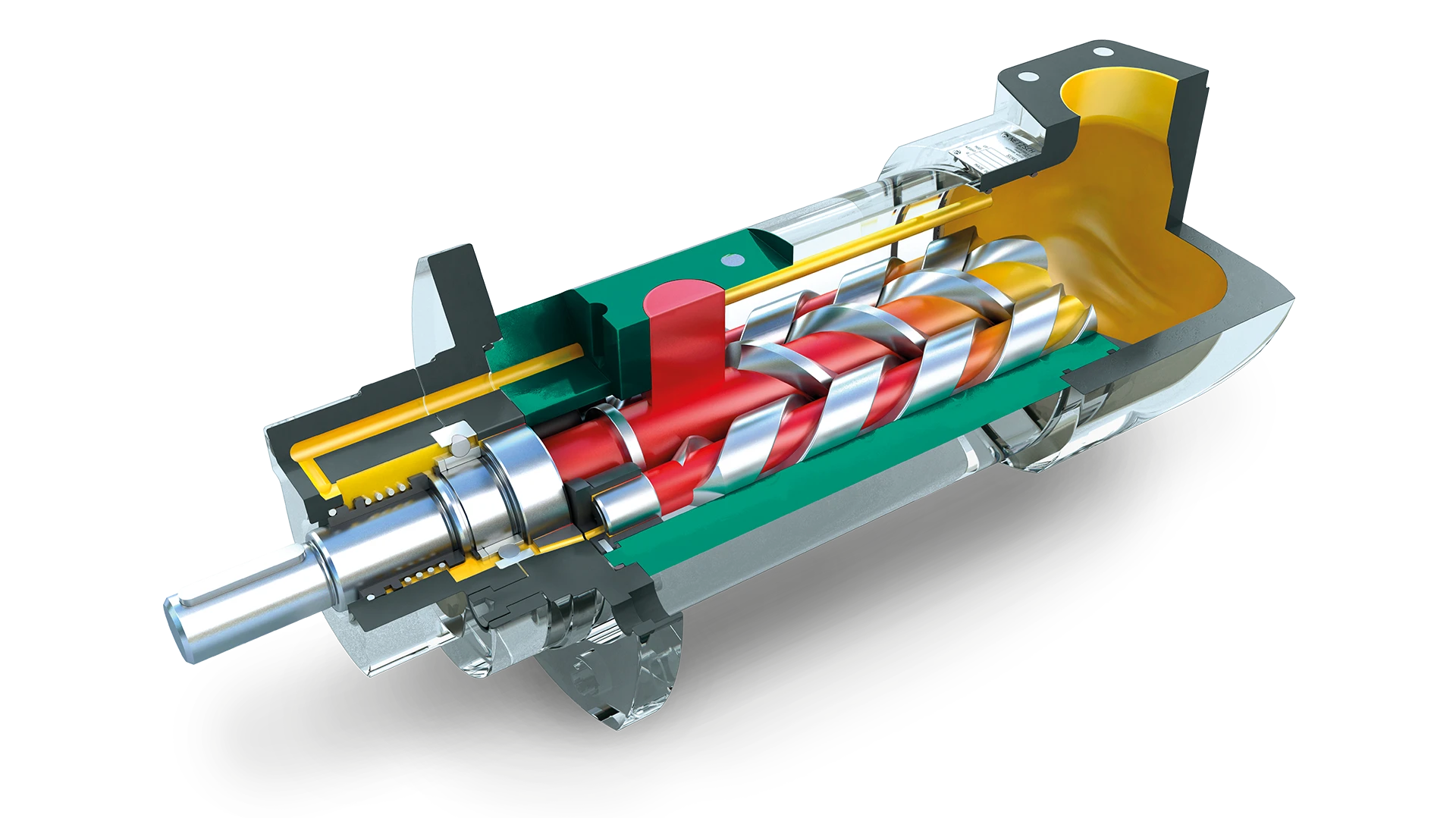

One of the main advantages of multi screw pumps is their high energy efficiency. This allows you to reduce your operating costs significantly. Thanks to the optimised spindle design, this technology achieves an exceptionally high efficiency level, which consumes significantly less energy than other pump types. Highly precise tolerances in production characterise multi screw pumps. The result is a reduction in energy costs and promotes sustainable production. Whether you need to pump low or high viscosity liquids, self-priming multi screw pumps offer a powerful and energy efficient solution reducing the total cost of ownership and helps you to achieve your efficiency goals.

Multi screw pumps: Benefit from their versatility

Multi screw pumps stand for versatility in every aspect. Designed to handle a wide range of media efficiently, these pumps can overcome challenges with liquids of almost any viscosity. Their adaptability ideally suits a wide range of industries, from food processing to chemical production, where different media must be transported safely and efficiently. Furthermore, the innovative spindle technology enables precise dosing and a constant, pulsation-free flow rate. This not only protects the pumped medium but also downstream pipework and systems. By opting for a multi screw pump, you are investing in a solution that is not only technically state-of-the-art, but also reduces your costs in the long term.

Consistent flow rate thanks to multi screw pumps

Is continuous and reliable operation essential for your industrial process? In this case, multi screw pumps are the right choice. Thanks to their precise and innovative spindle technology, these pumps deliver a constant, pulsation-free flow, making them ideal for applications with a continuous liquid supply. This feature is particularly beneficial for sensitive production processes in the pharmaceutical, food and cosmetics industries, where any fluctuation in flow rate can affect product quality. In addition, there is no contact between the rotating spindles. This significantly reduces the load on the pump components and, therefore, increases the service life of your entire system.

Multi screw pumps: Reliability under extreme conditions

Multi screw pumps are specially designed for high pressure applications and offer high reliability even under the harshest operating conditions. These pumps can continuously generate high pressures, making them ideal for industries where liquids must be transported over long distances or against large resistors, such as in the oil and gas industry or mining. The robust design of the pumps ensures long life performance, minimising the risk of failure and improving the safety and efficiency of your processes. Multi screw pumps also fulfil numerous international standards, such as those of the American Petroleum Institute (API).

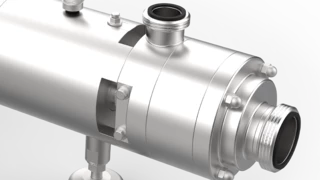

Longevity guaranteed: Robust multi screw pumps

Further advantages of multi screw pumps are their robust design and long service life. Thanks to high quality materials and state-of-the-art manufacturing techniques, these pumps can withstand even the most demanding operating conditions, from abrasive to corrosive media. This resistance not only minimises your maintenance requirements but also extends the service life of the pumps. You will benefit from low downtime and reduced operating costs, while you can expect consistent and reliable performance. In addition, multi screw pumps require a tiny footprint. This makes them suitable even for applications where space is limited, such as in the marine or process industries.

High Efficiency

No metal to metal contact

Small footprint

How to minimise noise thanks to multi screw pumps

Multi screw pumps are characterised by their quiet operation. This not only protects downstream pipework and systems but also improves the working environment for your employees. The innovative design of multi screw pumps significantly reduces vibrations and noise, ensuring compliance with strict noise regulations. Particularly in production environments where people have to spend long hours, the noise caused by gear pumps, for example, can lead to stress and even health problems in the long term. You can reduce the noise level in your system through the use of multi screw pumps.

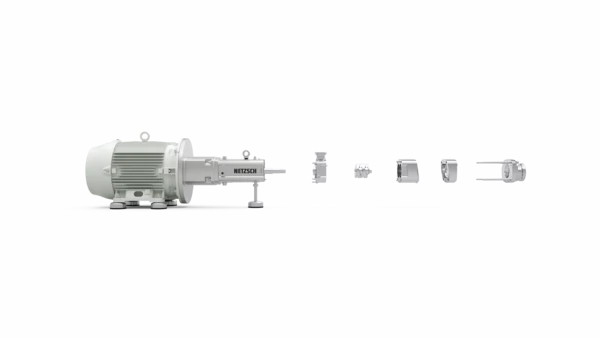

Multi screw pumps: Customisable to your requirements

Customised solutions specifically tailored to your requirements – this is precisely what multi screw pumps stand for. Thanks to the modular design of these pumps, adjustments can be made to the choice of material, sealing technology and configuration to optimise the media to be pumped, and the process conditions in your production. Regardless of extreme temperatures, high viscosities or corrosive liquids involved, the flexibility of the pumps allows them to be precisely customised to your needs, which increases the efficiency and reliability of your processes.

75000

210

70

Applications where to benefit from multi screw pumps

Multi screw pumps are indispensable in various industries and applications due to their versatility and efficiency. They are particularly suitable for chemical and petrochemical industries, where they reliably pump aggressive and hazardous media. In the food and beverage industry, you also benefit from the gentle, hygienic pumping of sensitive liquids. In the oil and gas industry, on the other hand, this technology offers you an efficient and safe solution for pumping crude oil and other fluids at high pressures. In addition, multi screw pumps are ideally suited for the precise dosing and handling of highly viscous and sensitive media in the pharmaceutical industry. The robust design and adaptability of multi screw pumps make them the preferred choice for applications that require maximum reliability and performance.

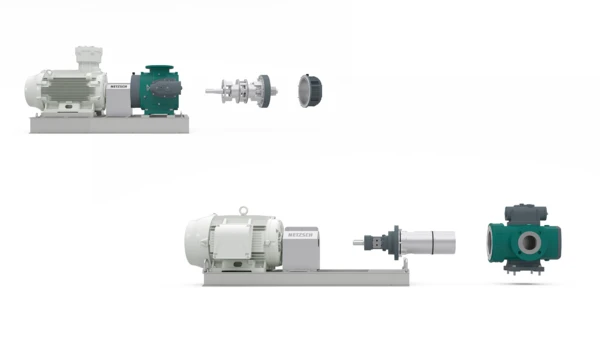

Multi screw pumps in the NETZSCH portfolio

Do you want to benefit from the advantages of multi screw pumps? In that case, NETZSCH Pumps & Systems is your ideal partner. With NOTOS® multi screw pump technology, the global specialist in handling complex media has particularly efficient and reliable pumps in various designs in its portfolio. All models at a glance:

In addition to multi screw pumps, NETZSCH also offers NEMO® progressing cavity pumps, TORNADO® rotary lobe pumps, PERIPRO® peristaltic pumps, as well as barrel emptying and grinding systems. Our service and support do not end with the purchase. Our services go far beyond that. We support you with everything from advice, maintenance, and spare parts to repairing and modernising your pump and promise you Proven Excellence – outstanding performance in all areas.