个案咨询

沼气基质导致泵的高磨损

沼气生产中的不同基质对泵提出了不同的挑战。一方面,一些介质具有腐蚀性,如液态肥料,有些纤维状的介质可能会造成堵塞,如谷物废料。另一方面,动物源性材料也必须在高温下处理以防止疾病传染,因此一些介质在输送时温度仍然处于70~80°C。这导致沼气行业泵的高磨损,以及相关的运营成本增加。另一个挑战是私人生物发电厂场地所需的空间很小。

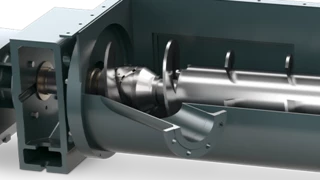

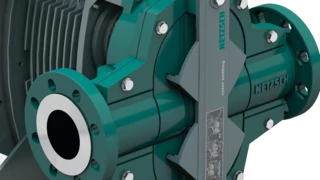

采用FSIP®在线全服务和xLC®定子调节系统的NEMO® BY单螺杆泵,您可以减少维护时间。

所有系统都具有非常紧凑的设计,并且是带有法兰安装电机的直联式结构,这节省了大量空间。高效的泵设计还需要很少的电力,加上较长的使用寿命和维护周期,从而降低了总体运行成本。作为泵送复杂介质的全球专家,耐驰泵&系统始终为您的应用找到合适的解决方案。