BIO-FOOD waste Pumps

Food Waste Pumps for Biogas Production Plants

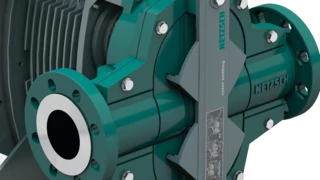

NETZSCH offers ideal pump solutions for transferring organic food waste by using progressing cavity pumps in biogas production plants. NEMO® progressing cavity pumps handle everything from slurry to waste.

In biogas production, substrates with a wide variety of properties must be pumped. The range of pumped materials extends from corn silage, liquid manure, grape pomace, and food waste to fats and dairy products. As the global specialist in the field of environment & energy, NETZSCH Pumps & Systems offers you innovative bio food waste pump solutions for pumping substrates in the biogas industry.

We will show you how bio food waste pumps are working and benefit from using a high-performance and space-saving NEMO® progressing cavity pumps in the biogas production plants.

Individual Consulting

Bio- Waste Food Pumps are a high load pumps due to changing substrates

In Germany, as WWF experts estimate, 18 million tonnes of food end up in the rubbish yearly. Food waste is steadily increasing. Agrivalor Energie, a company based in Alsace, operates its combined heat and power plant primarily with biogas from food production residues and substrates such as food that can no longer be sold. Thus, sustainable gas can be produced from discarded food. The mixture of manure, maise silage, and, among other things, food waste from restaurants is pumped into a fermenter and turned into biogas. The changing mixtures of substances place high stress on the pumps and systems.

How do biowaste food pumps transfers biogas substrates leading to high pump wear and tear?

The different substrates in biogas production pose different challenges for the pumps. On the one hand, some of the media are corrosive, for example, liquid manure or fibrous and prone to clogging, such as grain waste. On the other hand, substrates of animal origin have to be intensely heated for hygienisation for reasons of disease protection, which means that many media are still 70 to 80 degrees Celsius when they are transported further. This leads to high wear and tear on the pumps in the biogas sector, as well as the associated increase in operating costs. Another challenge is the small amount of space required on the site of the private bio-power plant.

How progressing cavity pumps are used in biogas production plants?

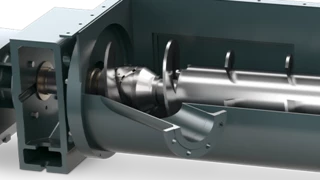

To achieve high operational reliability, low maintenance and downtime despite the challenges of pumping substrates in biogas production, Agrivalor Energie opted for NEMO® BY progressing cavity pumps from NETZSCH. The space-saving NEMO® pumps convey various substrates in biogas production without significant maintenance or downtime. In addition, the progressing cavity pumps impress with their long service life. Even the high dry matter content of about six to seven percent presents no problems for the progressing cavity pumps. Two pumps deliver around 40 m³/h of the mixture from the collection tank to the fermenter in start/stop operation. Further NEMO® pumps with a capacity of 20 m³/h are used in recirculating, pumping and feeding the hygienist hot slurry into the mixer.

All systems have a very compact design and are of block construction with a flange-mounted motor, which saves a lot of space. The efficient pump design also requires little electricity, which, together with the long service life and maintenance intervals, results in a low total cost of ownership. As a global specialist for pumping complex media, NETZSCH Pumps & Systems always finds the right solution for your application.

NEMO® BY progressing cavity pump in Biogas Production Plants

- Medium: Maize silage, liquid manure, grape marc, food waste, fats and dairy products

- Temperature: 70 up to 80 °C

- Conveying capacity: 20 up to 40 m³/h