Bio waste

Long Service Life When Pumping Substrates in Biogas Production

NEMO® progressing cavity pumps handle everything from slurry to waste

In biogas production, substrates with a wide variety of properties must be pumped. The range of pumped materials extends from corn silage, liquid manure, grape pomace, and food waste to fats and dairy products. As the global specialist in the field of environment & energy, NETZSCH Pumps & Systems offers you innovative solutions for pumping substrates in biogas.

We will show you how you benefit from using a high-performance and space-saving NEMO® progressing cavity pump.

Individual Consulting

High load on the pumps due to changing substrates

In Germany, as WWF experts estimate, 18 million tonnes of food end up in the rubbish yearly. Food waste is steadily increasing. Agrivalor Energie, a company based in Alsace, operates its combined heat and power plant primarily with biogas from food production residues and substrates such as food that can no longer be sold. Thus, sustainable gas can be produced from discarded food. The mixture of manure, maise silage and, among other things, food waste from restaurants is pumped into a fermenter and turned into biogas. The changing mixtures of substances place high stress on the pumps and systems.

Biogas substrates lead to high pump wear and tear

However, the varying mixtures of materials put a major strain on the plant’s conveying systems. Some of the materials, such as the liquid manure, are corrosive and some are fibrous and likely to cause obstructions, such as grain waste. Materials of animal origin also have to be exposed to intense heat to prevent disease, so some products are still at 70 or 80°C when they are conveyed.

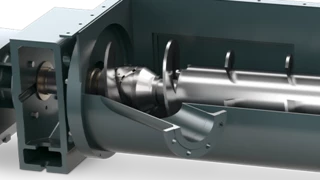

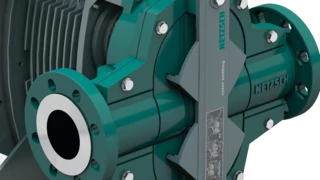

Progressing cavity pump for substrates in biogas production

To achieve high operational reliability, low maintenance and downtime despite the challenges of pumping substrates in biogas production, Agrivalor Energie opted for NEMO® BY progressing cavity pumps from NETZSCH. The space-saving NEMO® pumps convey various substrates in biogas production without significant maintenance or downtime. In addition, the progressing cavity pumps provide long service life. Even the high dry matter content of about six to seven percent presents no problem for the progressing cavity pumps. Two pumps deliver around 40 m³/h of the mixture from the collection tank to the fermenter in start/stop operation. In addition, NEMO® pumps with a capacity of 20 m³/h are used in recirculating, pumping and feeding the hygienist hot slurry into the mixer.

Agrivalor Énergie ordered ten NETZSCH-made NEMO® progressing cavity pumps to achieve maximum possible reliability without significant maintenance or downtimes, despite the tough conditions. Two of the larger pumps with capacities of around 40 m³/h are used to transport the mixture from the collecting tank (with around six to seven percent dry matter content) into the fermenter. Other NEMO® pumps with a capacity of 20 m³/h are used to convey the recirculated substance and introduce the sanitized hot liquid manure into the mixer. All the units are extremely compact and have a block design with flange-mounted motor, saving a lot of space on the premises of the privately owned biogas plant. The efficient pump design only requires minimal power, which – along with the long service life and long maintenance intervals – leads to low overall operating costs.

NEMO® BY progressing cavity pump in industrial design

- Product: Maize silage, liquid manure, grape marc, food waste, fats and dairy products

- Temperature: 70 up to 80 °C

- Conveying capacity: 20 up to 40 m³/h