19.02.2024

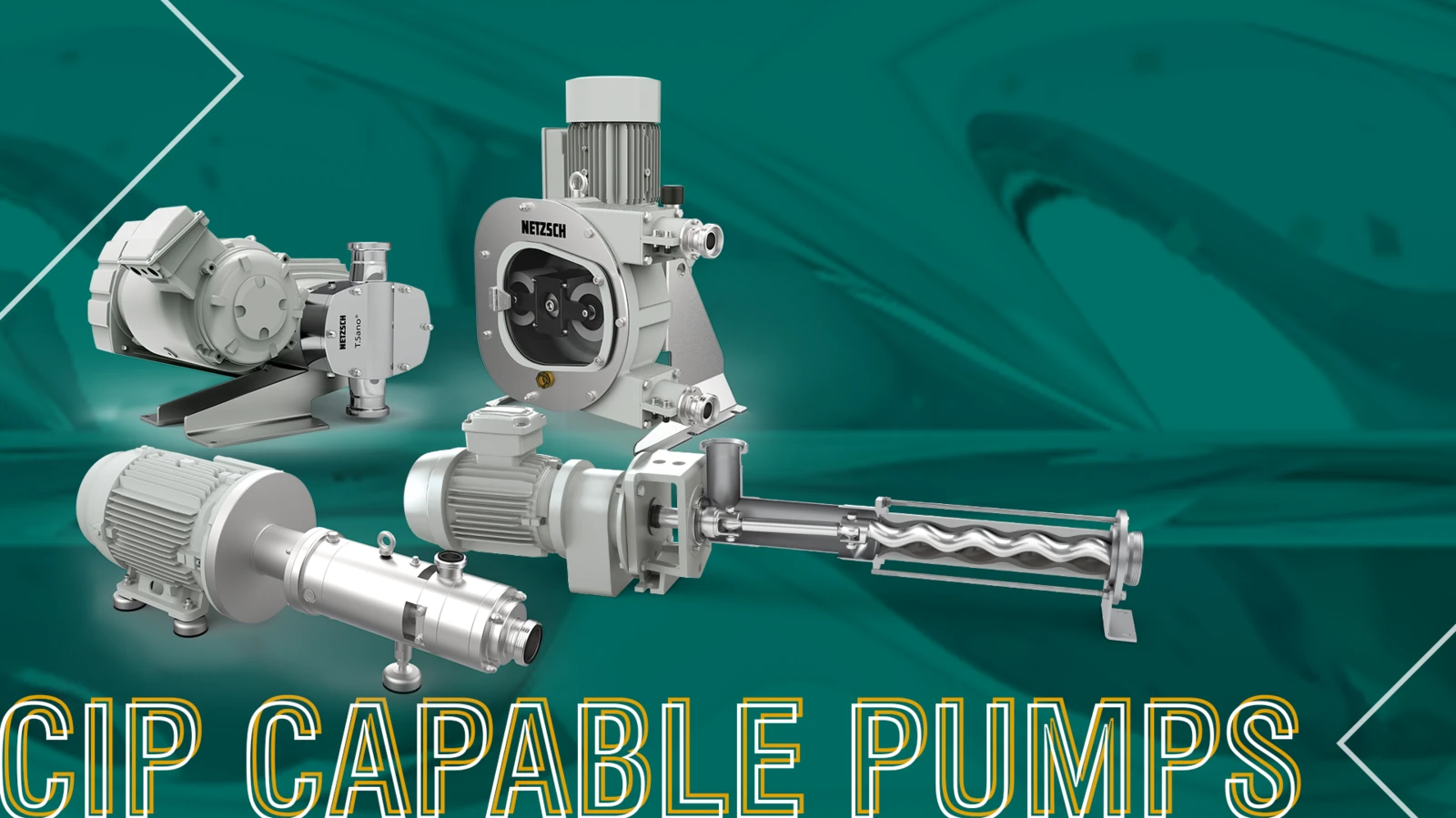

How to Benefit From CIP Capable Pumps in a Wide Range of Applications

Efficient cleaning, increased productivity and sustainable cost savings: This is precisely what CIP capable pumps from NETZSCH offer you. As a global specialist in handling complex media, NETZSCH Pumps & Systems has numerous designs and technologies in its portfolio.

We will show you how you to benefit from CIP capable pumps in a wide range of applications such as the food industry, the chemical industry or the pharmaceutical industry.

Customised Consulting

CIP capable pump? Everything you need to know

What does CIP capability mean? Before we show you the advantages of CIP capable pumps, we have to clarify what CIP stands for. CIP means “Cleaning in Place”. It is a method of cleaning production systems, pipelines, tanks and other equipment, such as pumps, without dismantling them. CIP enables efficient and thorough equipment cleaning to remove impurities, residues or bacteria. This is particularly important in industries such as food production, pharmaceuticals and beverage production, where strict hygiene standards must be maintained. CIP systems are often used with special CIP capable equipment such as pumps, valves and piping to ensure an automated and standardised cleaning process.

How to increase your cleaning efficiency with CIP capable pumps

Are you wondering how to optimise your cleaning process? Efficient cleaning, a significant benefit of CIP enabled pumps, is revolutionising the cleaning process in industrial plants. The ability to perform cleaning cycles without the need for disassembly saves you valuable time and increases the overall efficiency of your production plant. This is particularly crucial in industries with strict hygiene regulations, such as the food and pharmaceutical industries. Thanks to the CIP capability of pumps, automated cleaning allows you to control and monitor the cleaning process precisely. In addition to reducing labour costs, this also helps you to comply with even the strictest hygiene standards. In addition to the highest product quality, using CIP capable pumps optimises your resource use while promoting an effective production environment.

CIP capable pumps sustainably increase productivity

Do you want to increase the productivity of your plant? The use of CIP capable pumps makes it possible. By implementing CIP capable pumps, you can significantly increase the productivity of your system. Even the possibility of automating the cleaning process and carrying it out without costly downtimes optimises the overall performance of your system. This is because reducing manual cleaning frees up valuable production hours. This leads to an increase in overall productivity. Automated cleaning guarantees consistent and standardised cleaning quality, which is particularly important in industries with strict quality standards, such as the food and pharmaceutical industries. You can also organise your production processes more efficiently by saving time and resources. This ultimately leads to improved productivity and profitability of your plant.

Resource-friendly cleaning thanks to CIP capable pumps

How to save resources with CIP capable pumps? CIP capable pumps are decisive in resource efficiency in industrial process plants. These pumps allow you to control and automate cleaning processes precisely. As a result, you optimise the use of cleaning agents, water and energy. Through the targeted use of cleaning cycles, you minimise the consumption of these resources without compromising the effectiveness of the cleaning process. The ability to automate the cleaning process not only helps to reduce water consumption and minimise waste but also has a positive impact on the energy efficiency of your system. Therefore, CIP-capable pumps ensure compliance with strict hygiene standards and, at the same time, promote sustainable and resource-efficient operation of production facilities.

50.000

How to reduce your costs thanks to CIP capable pumps

Do you want to reduce your production costs? Using CIP capable pumps leads to significant cost savings in industrial process plants. Although the initial investment for CIP enabled equipment may be higher, these costs pay off in the long term through various savings. Automating the cleaning process significantly reduces the need for manual labour hours, thereby reducing your labour costs. At the same time, efficient cleaning without downtime enables higher plant utilisation. This increases overall productivity. In addition, the precise control of cleaning cycles reduces the consumption of cleaning agents, water and energy. These factors, combined with the avoidance of cross contamination and compliance with even the strictest hygiene standards, help you to increase your cost efficiency in the long term, giving you a competitive advantage.

CIP capable pumps sustainably increase productivity

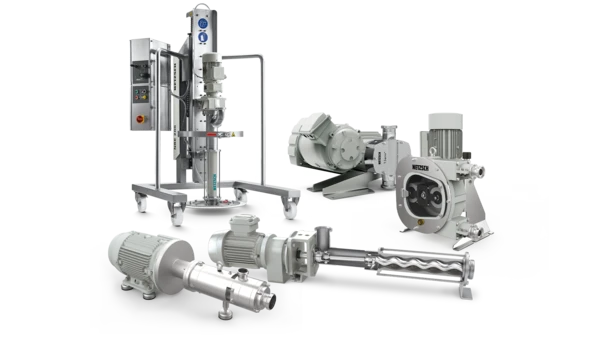

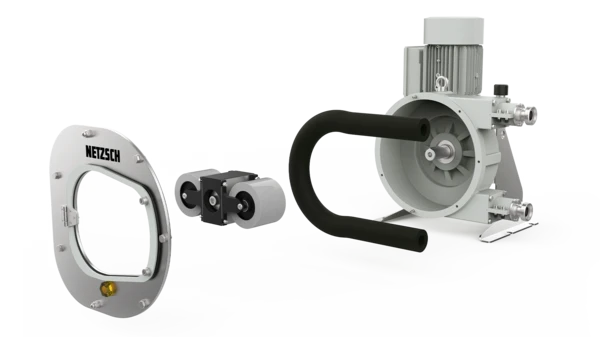

Which pumps are CIP capable? NETZSCH offers you four different CIP capable pump technologies. In addition to the proven technology of the NEMO® progressing cavity pumps and the TORNADO® rotary lobe pump, the portfolio also includes NOTOS® multi screw pumps and, for a few years now, PERIPRO® peristaltic pumps. All four product groups also have CIP and SIP capable versions. Depending on the design, cleaning or sterilisation can be done without an additional auxiliary system or pump.

This means nothing stands in the way of efficient cleaning and the associated cost savings. What are you waiting for? Contact the experts at NETZSCH, and find the perfect CIP capable pump solution for your application.