Products & accessories

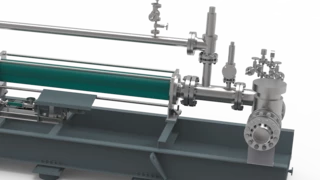

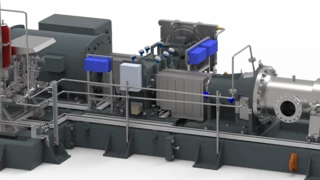

NEMO® Progressing Cavity Pumps From NETZSCH:

Have a wide range of applications and are used in many markets

NEMO® Progressing Cavity Pumps have an extensive industrial application range for the continuous, pressure-stable, gentle and low-pulsation conveyance of almost any substance. Whether for sludge, chemical substances, adhesives, petroleum or yogurt, we can meet your requirements with the proper combination from our selection of eleven NETZSCH pump types, four rotor/stator geometries and our variety of engineered joints. Our valveless positive-displacement pump design can even transport stringy material. Contact us to help select the right pump for your job.

Individual Consulting

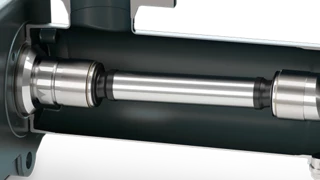

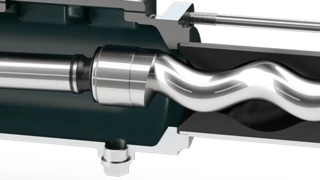

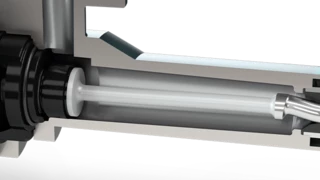

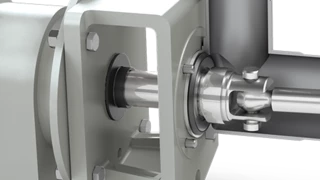

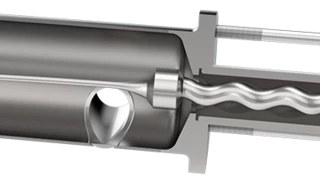

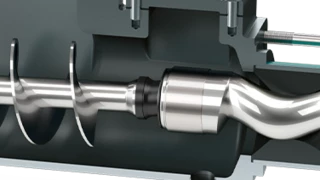

The technology of the progressing cavity pump

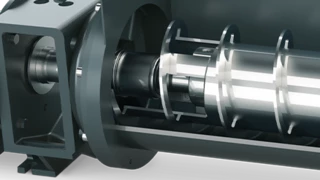

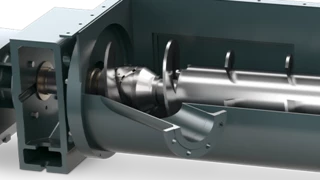

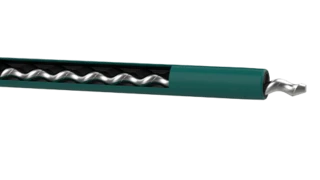

Progressing cavity pumps belong to the group of positive displacement pumps. The main components are a rotating rotor and a stationary stator. The rotor, hinged or elastically attached on one side, is a round-threaded screw. On the output side, the axial position oscillates. The hollow stator is elastic and has the same pitch length as the rotor. This leaves conveying spaces between the stator and the rotor, which move continuously from the inlet to the outlet side. The size of the cavities and the associated delivery rate depends on the size of the construction. Except for the rotor and stator, all other components are identical.

So, if the flow rate or pressure of already installed NEMO® progressing cavity pumps is subsequently changed, they can be adapted to the new operating conditions by simply replacing the rotor and stator. Since the shape of the cavities is always constant, the pumped product is not compressed. This allows you to pump not only fluids but also solids. Due to the insignificant shear forces, you can even pump whole fruits undamaged. Another advantage of the valveless progressing cavity pump type is that they convey continuously and with low pulsation. Even highly viscous and abrasive product can be pumped safely and without problems. They are also suitable as submersible pumps in wells and with open end connections for emptying barrels.