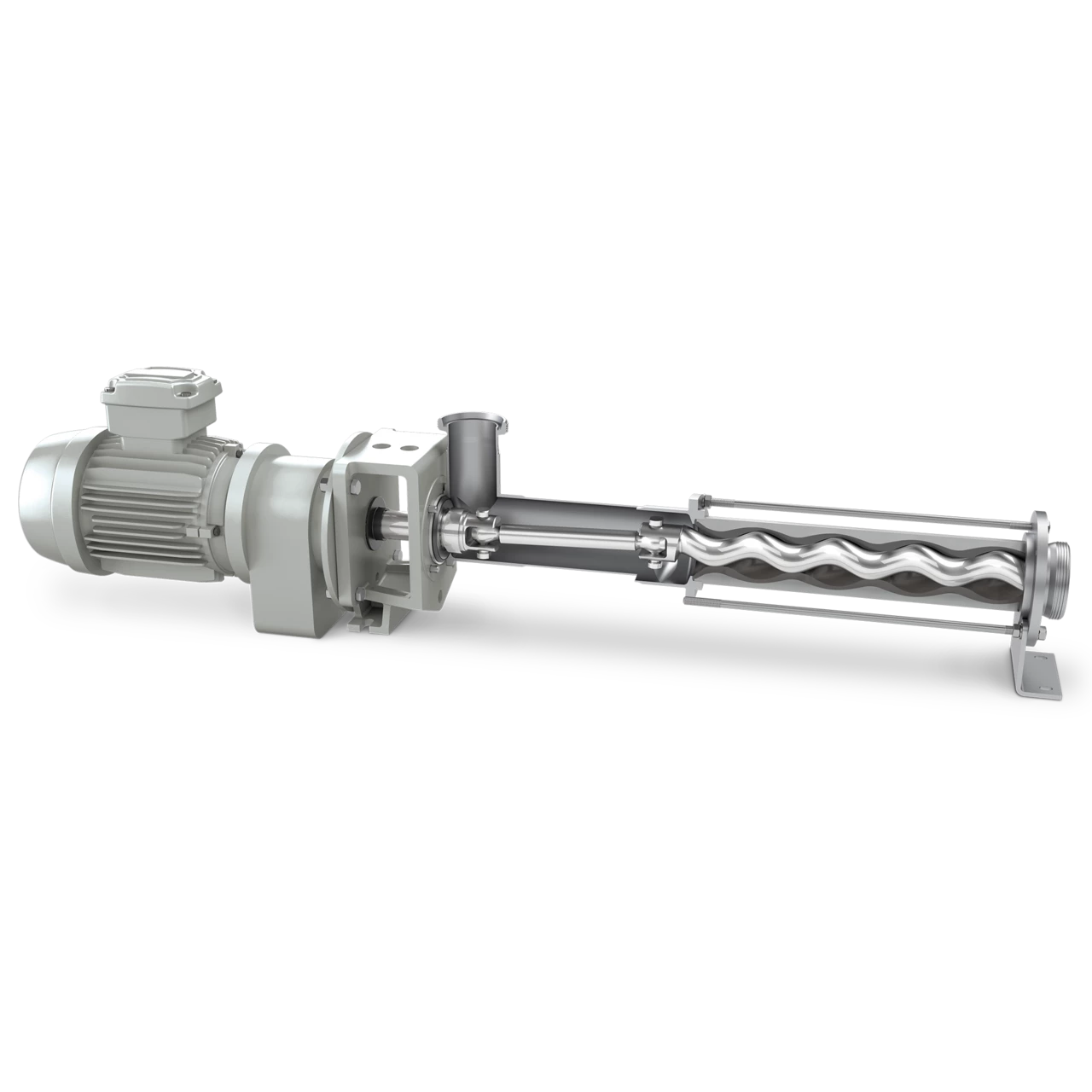

The NEMO® BH hygienic pump in compact block design is used for hygienic applications in the food, pharmaceutical, cosmetic and chemical/biochemical industries because of its optimal process characteristics.

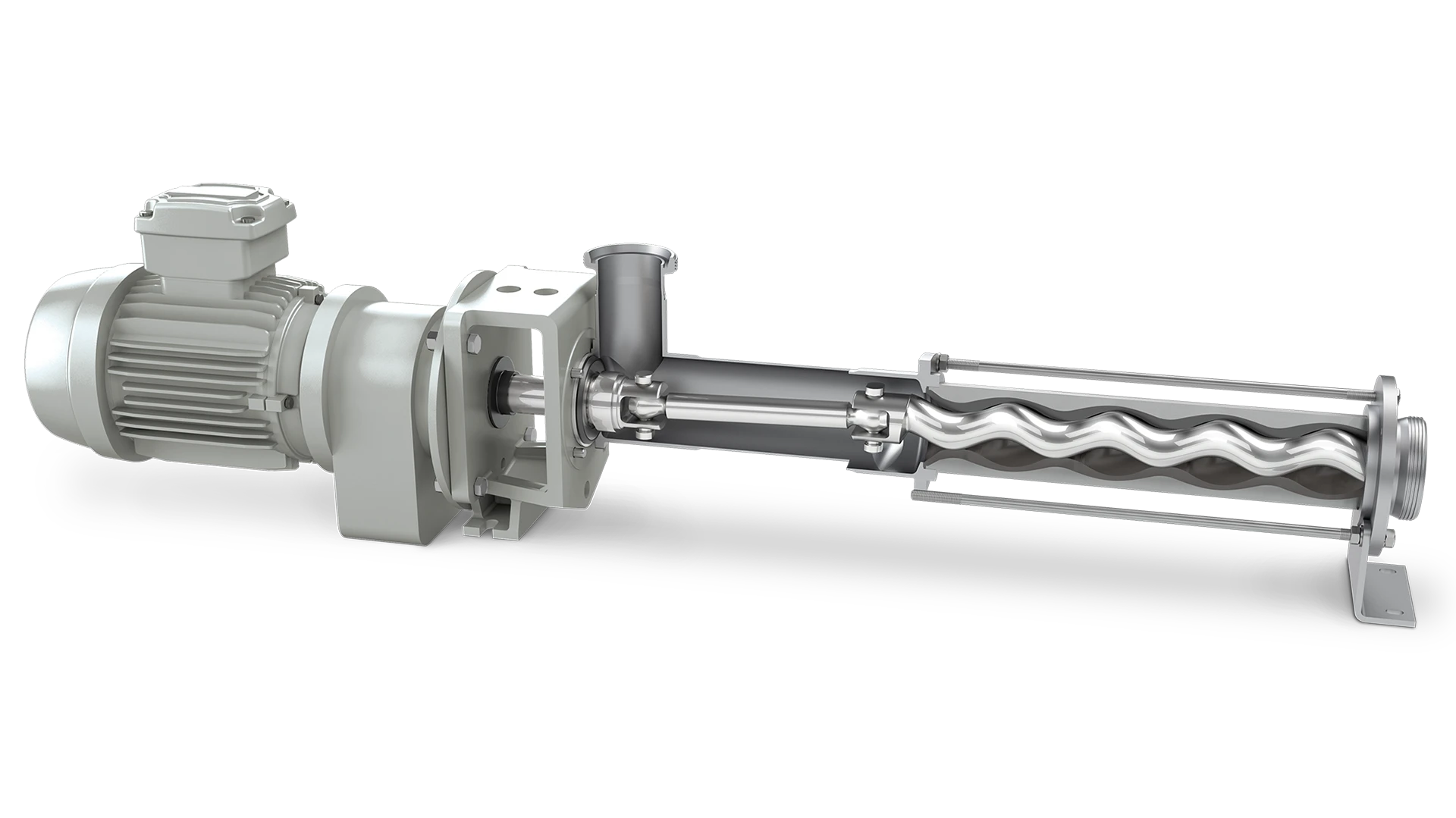

The NEMO® BH Sanitary Advanced Pump is employed in the food products, pharmaceutical, cosmetic and chemical/biochemical industries for sanitary applications and optimal cleaning. The important capabilities include, the continuous, pressure-stable, gentle and low-pulsation pumping and metering in proportion to speed. The block pump construction with flanged drive is particularly compact and economical to operate.

Various different regulatory bodies have set specifications for a hygienically correct configuration of components and machines, as well as for component cleanability. The materials used are approved by the FDA (Food and Drug Administration) as well as EU-VO 1935/2004. In addition, NEMO® Hygienic and Aseptic Pumps meet the specifications of the United States’ 3-A Sanitary Standards and are GOST-R certified (a Russian certificate of conformity).

Features of the NEMO® BH Sanitary Advanced Pumps:

- continuous low-pulsation pumping unaffected by fluctuations in pressure and viscosity

- capacity in proportion to rotation speed with high metering precision over a broad rotational-speed range

- high suction and pressure capability without valves

- reversible pumping direction

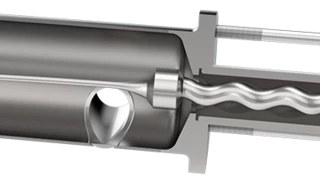

- stator with chamfered entrance for optimal filling of the conveying chamber

NEMO® BH Sanitary Advanced Pumps offer you:

- gentle product handling

- long production cycles with contamination-proof, sterile pump construction

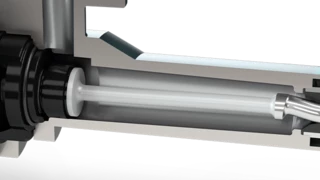

- CIP and SIP capability

- product handling under vacuum conditions up to almost an absolute vacuum

- open, patented sanitary joints for sticky products

- elastomers approved for food products in accordance to FDA

- horizontal and vertical installation

- easy serviceability

Advantages of the NEMO® BH Sanitary Advanced Pump:

- shaft seals suitable for food products with compression-proof bolted seal casing enable reversal of the direction of rotation, and so the direction of pumping, up to the maximum pump pressure

- streamlined, crevice-free housing model prevents product settling

- all product-contacting surfaces are polished to prevent product build-up and facilitate cleaning

- the pump housing and stator can be optionally heated

Take advantage of our decades of experience and expertise in positive displacement pump manufacture.

Your edge – process stability even under great demands!

NEMO® BH hygienic pump meets numerous hygiene guidelines

NEMO® pumps are designed, manufactured and tested in accordance with FDA (Food and Drug Administration) as well as EU VO 1935/2004. In addition, NEMO® hygienic and aseptic progressing cavity pumps meet the requirements of the 3-A Sanitary Standard of the USA and are GOST-R certified (certificate of conformity for Russia). The NEMO® BH is particularly compact and economical in block construction with flanged drive.

Individual Consulting

Advantages

Heating

Design

Vacuum

Technique

Worldwide service and support for your pump and system

Our service and support do not end with the purchase. From consultation, spare parts and maintenance to the repair and modernization of your pump - we support you right from the start.

With the help of our worldwide service network, we are ready for you around the clock in case of an emergency.

Literature

- NEMO® Progressing Cavity PumpsBrochure

- Product PortfolioBrochure

- Food & PharmaceuticalBrochure

- MultiProtector: The Monitoring and Protection UnitBrochure

- SH Sanitary Advanced Plus PumpFlyer

- BH Sanitary Advanced Open Hopper PumpFlyer

- BY Sanitary Prime PumpFlyer

- BO Sanitary Prime Open Hopper PumpFlyer

- Independent ControlsBrochure

- Customer Service/AftermarketBrochure

Your contacts and companies at NETZSCH

Any specific questions? Contact us for help or fill in the contact form.