OFFSET COLOURS

Conveying Materials for Surface Coating

Replace your offset colour pump and halve unloading time

The paint and varnish industry is one of the most versatile and challenging application fields for pumps. The application areas include the reliable feeding of abrasive paper fillers, corrosive sizing agents, and the exact dosing of viscous offset colours and varnishes.

A renowned publishing company also faced this challenge and contacted the NETZSCH Pumps & Systems experts regarding its problem. As a global specialist in handling complex media, NETZSCH found the optimal solution for pumping the offset colours. We show you how to benefit from replacing your current offset colour pump.

Individual Consulting

These are the challenges to be aware of when pumping offset colours

One of the biggest problems for most conventional pumps when conveying offset colours is the need for more fluidity in the medium. Viscosities of 10,000 mPas and more, similar to viscous honey, are not uncommon. This means they are very dense and more resistant to flow movement. Pumps must handle this high viscosity and build enough pressure to move the fluid efficiently. Some colours and paints also contain pigments or other solid particles which are abrasive. These particles can damage the pump components, which reduces the service life. At the same time, maintenance and servicing costs increase for you. Another challenge when pumping offset colours is the residues in the unit, which can be difficult to clean. Together, these can lead to clogging or malfunctions and unplanned downtime. Therefore, regular maintenance and cleaning of offset colour pumps are essential to ensure optimum performance and longevity. Also, the colours contain solvents or other chemical ingredients that can react with the pump materials. Therefore, selecting suitable materials is elementary to avoid damage or contamination.

Unplanned downtime and high service costs when pumping offset colours

Previously, the publishing company used a diaphragm pump to transfer the offset colour from the transporter to the corresponding storage tanks. However, due to the high viscosity of around 10,000 mPas, it struggled with delivery breaks, resulting in long delays in unloading the trucks. In addition, maintenance work had to be carried out on the pumps frequently, which had to be removed and disassembled in a laborious process, resulting in high costs for the company. Therefore, the company contacted NETZSCH with its problems. The global specialist in handling complex fluids found a solution together with the manufacturer to solve the issues. After carefully evaluating the requirements and analysing the medium, they recommended replacing the previous diaphragm pump.

Pump offset colours efficiently and reliably with this pump

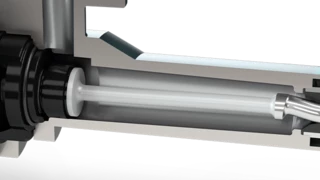

To increase performance and efficiency, the diaphragm pump was replaced by NEMO® BY progressing cavity pumps. With the NEMO® BY, you can gently convey even the most demanding media, such as offset colours, with low pulsation, regardless of pressure and viscosity fluctuations. The pump is optimally designed to convey abrasive liquids with high viscosity and solids content. For the offset colours in the particular application, a single-stage L-geometry was used for the rotor and stator, which enables a higher flow rate at low differential pressure. The chosen undersize of the rotor prevents excessive jamming and thus improves mechanical efficiency. The slim design of the progressing cavity pumps also allows the manufacturer to install four of these pumps - for the four different colours - together with frequency inverters on one carrier module. This is integrated into the base plate of the transport truck and can be easily removed. This provides you with free access to the devices in no time at all and allows you to carry out any maintenance work.

However, since the pumps work much more reliably than the diaphragm pumps, the maintenance intervals have been extended anyway. At the same time, the unloading time of the transporters has been almost halved. Therefore, high and unscheduled waiting times for tanker drivers do not longer exist. Thus, by replacing the offset colour pumps, the company has increased efficiency and reduced production costs. In addition to the example mentioned, displacement pumps from NETZSCH are also used in numerous other areas of the colour and paper industry, such as for transporting pigment slurries or additives and processing liquids or binders. In each case, however, the prerequisite is configuring the pump according to the application.

Contact the experts at NETZSCH and find the pump that is optimally designed for your application. This way, nothing will stand in the way of efficient pumping of even the most demanding media in the future.

NEMO® BY progressing cavity pump in industrial design

- Medium: Offset colours

- Viscosity: 10,000 mPas