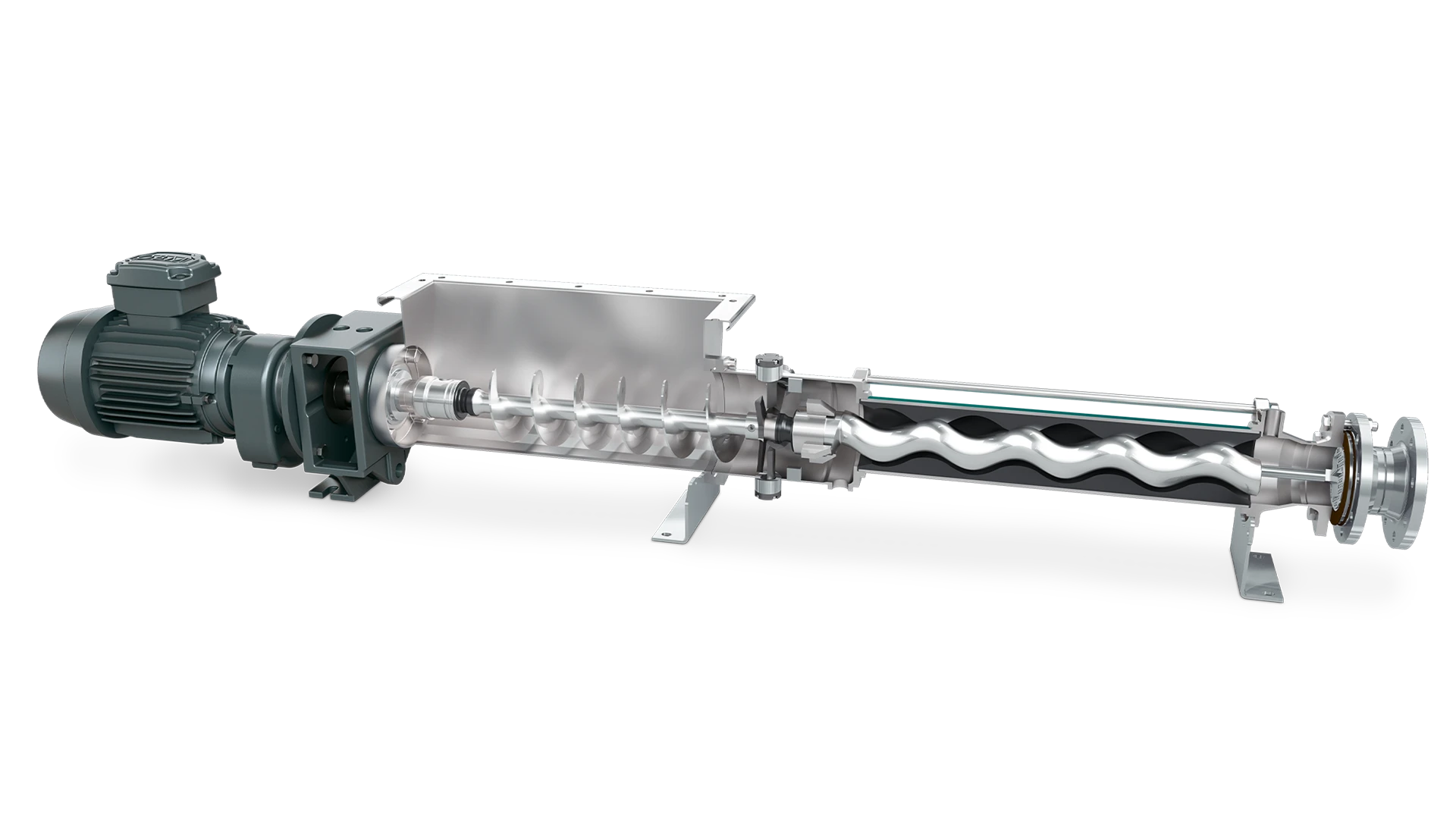

Conveying and cutting in one process step without expensive additional equipment, this is exactly what the NEMO® BO/SO hopper pump with integrated cutting device makes possible. With the progressing cavity pump, for example in the food industry, large solids such as particles of fruit or vegetables can be easily and quickly chopped and pumped for further processing.

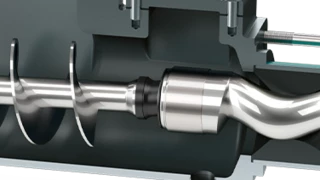

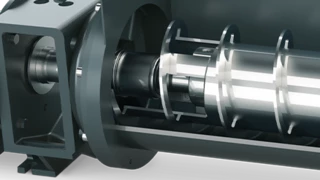

The NEMO® BO/SO progressing cavity pump with hopper and coupling rod with feeding screw and force-feed chamber is employed in almost all branches of industry to provide continuous, pressure-stable, gentle and low-pulsation conveyance. The hopper housing with cutting unit guarantees optimum feed of chunky medium into the conveying elements. If the medium passes the force-feed chamber with the cutting unit the larger fruits and vegetables are cutted immediately. This unit consists of a rotating knife with three blades and a variable number of stationary knives adjustable to the size and consistency of the particles.

NEMO® BO/SO: Two process steps with only one pump

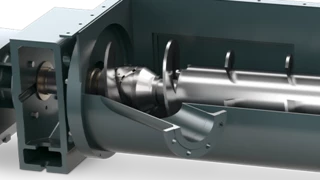

Optionally the pump can be equipped with an additional cutting unit at the discharge flange of the pump. With its perforated disc and rotating knife it allows for further fine definition of the particle size. As any other NEMO® progressing cavity pump also the BO/SO pump has the ability to dose the conveyed media in proportion to rotation speed. In block construction with a flanged drive, this pump is particularly compact and economical In addition, the NEMO® is characterised by low investment, operating and maintenance costs. However, it is also available in bearing block design with a free shaft end. This means that the pump can be operated with different types of drive, such as servo motors, diesel engines or hydraulic drives.

Individual Consulting

Advantages

Construction

Replace

Technique

Worldwide service and support for your pump and system

Our service and support do not end with the purchase. From consultation, spare parts and maintenance to the repair and modernisation of your pump - we support you right from the start.

Thanks to our worldwide service network, we are ready for you around the clock in case of an emergency.

Your contacts and companies at NETZSCH

Any specific questions? Contact us for help or fill in the contact form.