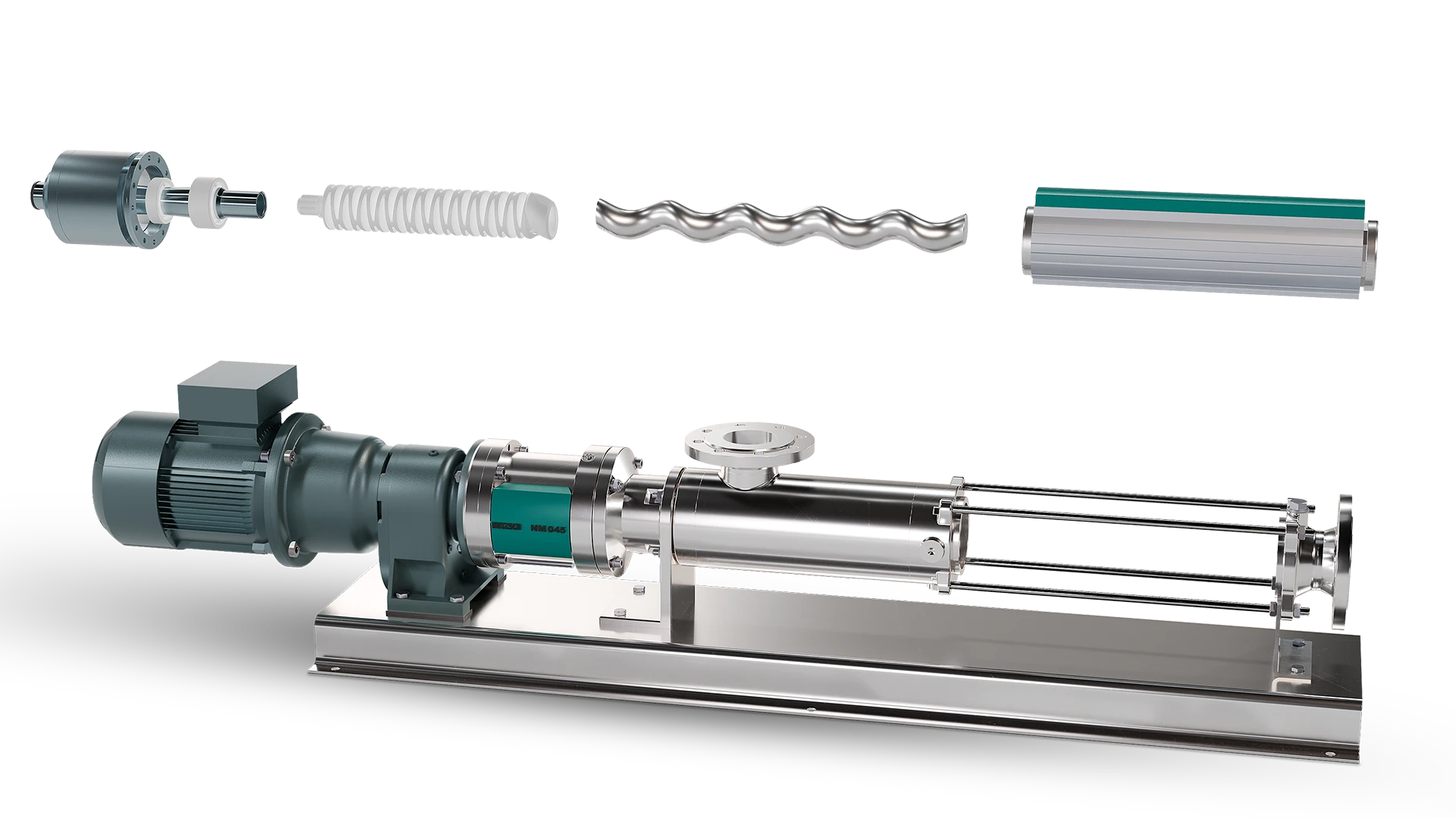

Safe and cost-effective pumping of hazardous media: The NEMO® MY magnetically coupled pump, specially developed for handling slurries with high viscosity, makes it possible.

The magnetically coupled pump from NETZSCH is hermetically sealed. This prevents aggressive, toxic or abrasive liquids and gases from escaping. The leakage-free pump guarantees maximum safety for your employees and the system. While the failure of a mechanical seal system leads to a seal leak, this is prevented with the NEMO® MY thanks to the magnetic coupling. The magnetic coupling is also less cost-intensive than a pump with a mechanical seal or other sealing system. This allows you to reduce your costs and make production even more efficient.

NEMO® MY magnetically coupled pump: Maintenance-free sealing

Another advantage of the NEMO® MY magnetically coupled pump is that the sealing system requires no maintenance. By using a magnetic coupling, it is unnecessary to ensure that there is always a constant sealing pressure and that the fluid level of the sealing system is maintained. In addition, the magnetically coupled pump, specially developed for pumping slurries, allows you to pump media with viscosities of up to 20,000 cps. The pump is also compliant with ATEX and can be used in potentially explosive atmospheres without problems.

Individual Consulting

Advantages

Hermetically sealed

Ideal for viscous media

Easy to maintain

Technique

Worldwide service and support for your pump and system

Our service and support do not end with the purchase. From consultation, spare parts and maintenance to the repair and modernisation of your pump - we support you right from the start.

Thanks to our worldwide service network, we are ready for you around the clock in case of an emergency.

Your contacts and companies at NETZSCH

Any specific questions? Contact us for help or fill in the contact form.