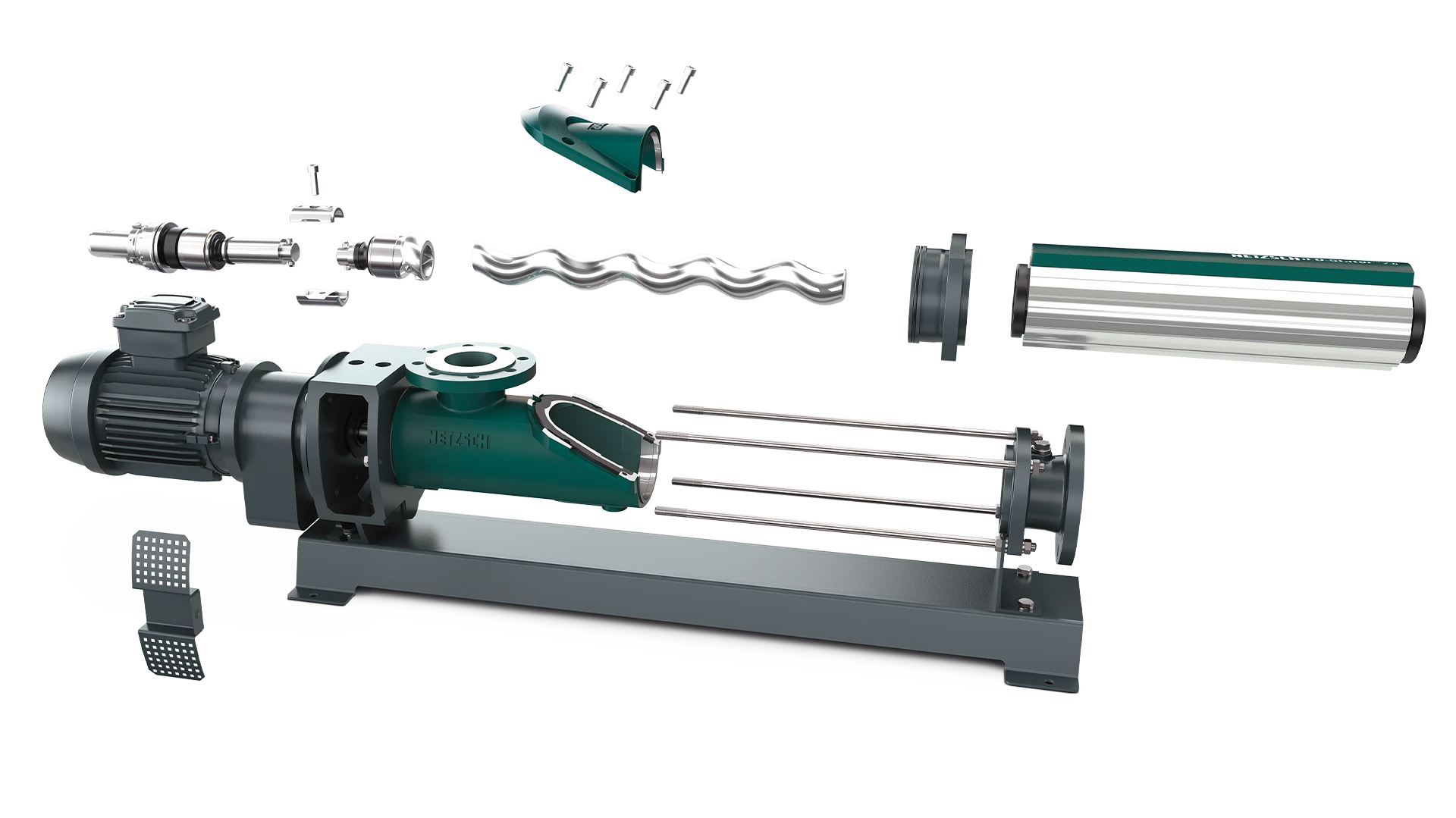

NETZSCH Pumps and Systems offer progressing cavity pumps in Full-Service-In-Place (FSIP) specially designed for easy maintenance, parts replacement, costs, & save up to 66% of servicing time, the NEMO®progressing cavity pumps in FSIP® design make it possible. They are available in three variants and can generally be used in all industrial area where very different media have to be conveyed with low pulsation, as well as unaffected by fluctuations in pressure and viscosity, or dosing tasks.

The FSIP® concept of the NEMO® progressing cavity pump is especially interesting where pumps are installed in wear-intensive applications requiring more service and maintenance work. Every time the installer's workload is eased, additional work steps are avoided, and maintenance time is reduced, this enables savings in terms of capacities and costs. Up to 66 percent of working time can be saved when changing the stator.

The FSIP® pump is designed in a way that the housing itself functions as a support and orientation guideline. The special design enables each part automatically fits into its destination. Positioning is done automatically without further adjustments. Therefore, the change of all worn parts takes less than half of the time required so far.

NEMO® Progressing Cavity Pump: Save costs due to FSIP® design.

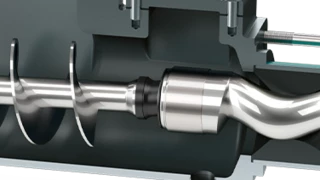

In block construction with a flanged drive, this NEMO® pump is particularly compact and economical. The pump also differentiates itself by means of low investment and operating costs. In FSIP® design the pump can help to save even more maintenance costs and costs caused by downtimes. The three variants are the FSIP.ready, the FSIP.advanced, and the FSIP.pro. The FSIP.ready is a basic BY Pump inclusive revised housing design with inspection cover, with the standard drive train and standard seal arrangement. The FSIP.advanced is a BY pump with a new housing design and large inspection cover, split coupling rod. The rotor and stator can be serviced in place. The FSIP.pro is also based on the BY pump with a new housing design and large inspection cover, split coupling rod, cartridge unit, and single-acting mechanical seal for "Full Service in Place". Two rotor/stator geometries are available to cover a broad spectrum of products and applications.

Individual Consulting

Advantages of NEMO® Progressing Cavity Pump

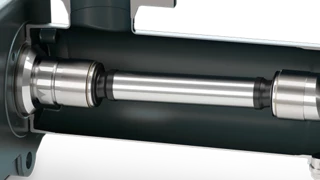

Rotor

FSIP® Design

Standards

NEMO® Progressing Cavity Pump Technique

Worldwide service and support for your pump and system

Our service and support do not end with the purchase. From consultation, spare parts and maintenance to the repair and modernisation of your pump - we support you right from the start.

Thanks to our worldwide service network, we are ready for you around the clock in case of an emergency.

Your contacts and companies at NETZSCH

Any specific questions? Contact us for help or fill in the contact form.