HYDRAULIC AND LUBRICATING OIL

Pumps for Varying Water Volumes in Hydroelectric Power Plants

How to benefit from using a multi screw pump for hydraulics and lubrication

The demand for alternative energy sources such as hydropower is steadily increasing. But uneven water flows pose significant challenges for man and machine worldwide. In particular, the pumps for the hydraulics and lubrication of the turbines in hydroelectric power plants, which weigh several tons, quickly reach their limits.

As a global specialist in complex fluid management, NETZSCH Pumps & Systems offers you the optimal pumping solution for the hydraulics and lubrication of turbines. We will show you how you can benefit from using a NOTOS® multi screw pump.

Individual Consulting

Hydraulic and lubricating oil pump prevents unplanned downtime

Electricity is generated in hydroelectric power plants using turbines. For example the largest Kaplan turbines in the country so far are running at the new Estreito power station on the Rio Tocantins. Their rotor alone weighs 470 tons. NETZSCH lubrication systems are being used at Estreito, so as to ensure the turbine support bearings and the guide bearing to the generators run consistently and without any wear or overheating.

Varying water quantities: With this oil pump, you remain flexible

The lubrication systems that meet these requirements include hydraulic and lubricating oil pumps, filters, heat exchangers, instruments, controls and lines. They are composed of two essential subsections, an injection unit and the actual lubricating oil circulation. Due to the enormous weight of the turbines resting on the bearings, the lubricant must be introduced at very high pressure, especially during start-up and shut-down. This ensures that a sliding film is created between the rotating and static components and prevents possible damage. The continuous lubricant supply and the return for cooling and filtration are handled by unique NOTOS® 4NS geared twin screw pumps. These pumps are not only used for bearing lubrication but also for turbine speed control. Permanent adaptation to a wide range of conditions is essential here. This allows you to react quickly to changing conditions and prevent spinning when the torque on the generator shaft drops.

Increase service life with innovative pump for hydraulic and lubricating oil

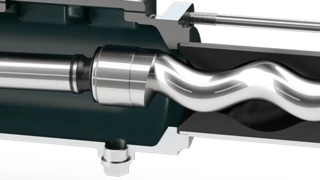

The NOTOS® multi screw pumps used to lubricate and control the hydraulics can generate exceptionally high pressure. This enables you to control the turbines, which weigh several tonnes hydraulically. The pumps consist of two spindle-shaped rotors whose sinuous profiling matches each other and the housing geometry. As a result, the screws interlock when they rotate, and sealed delivery chambers are formed in which the product is conveyed from the suction to the discharge side. The flow rate is determined mainly by the helix's pitch, the spindles' diameter and the shape of the spindle profile.

NOTOS® multi screw pumps which can generate a high pressure, are used here. These comprise two spindle-shaped rotors whose helical profiles are exactly attuned to one another and to the housing geometry. This means the screws intermesh as they rotate and sealed conveying chambers are formed in which the product is conveyed from the inlet to the discharge side. The capacity is substantially determined by the incline of the spirals, the diameter of the spindles and the shape of the spindle profile. Due to the hydraulic thrust compensation of the pump, the axial forces here are close to zero even for high pressures. In addition, an integrated spring-loaded overflow valve protects the system against overload. To achieve the longest possible service life and a high level of durability over the whole lifecycle, the screws are made of hardened nitride steel and the pump housing from cast iron. Furthermore, the precise adjustment of the interplay of the spindles is ensured over the long term by special bushings made of bronze.

NOTOS® 4NS geared twin screw pump

- Pressure: 68 bar

- Medium: Hydraulic and lubricating oil