Edible Fat and Oil

How to Reduce Your Maintenance Costs When Pumping Edible Fat and Oil

This is how you reduce wear and tear thanks to a change in pump technology

Maximise production rates, minimise wear and maintenance costs! You have undoubtedly heard announcements a thousand times if you work in the food industry. But how can you increase your efficiency? A manufacturer of edible fat and oil was faced with precisely this question.

NETZSCH Pumps & Systems, the global specialist in complex fluid management, has the solution to increase your production rates when pumping edible fat and oil and reduce wear simultaneously. We will show you how to sustainably reduce your costs by changing your pump.

Individual Consulting

Why are gear pumps not suitable for edible fat and oil?

At the mentioned edible oil manufacturer, barrels of 50 to 200 liters, IBC containers (Intermediate Bulk Container) and entire tankers with a volume of almost 30 cubic meters must be filled with different types of edible fat and oil within a maximum of one hour. A stationary conveyor system is not an option because of the different types of transport containers. Until now, a gear pump mounted on a small trolley was used. However, this did not function satisfactorily because the pump gear wheels were too heavily stressed. The high viscosity led to friction and associated heavy wear inside the gear pump. In addition, the grease decomposed due to the high temperatures in the pump, which led to contamination and blockage. The heavy-duty pumping of edible fat and oil caused enormous wear and tear, increasing costs for the edible oil producer.

Requirements for pumping edible fat and oil

According to the manufacturer, barrels of 50 to 200 liters, IBC barrels and complete tankers of 30 cubic meters volume had to be filled within a maximum of one hour with different types of edible oils. Due to the different types of containers for transportation, stationary delivery equipment cannot be considered, instead, up to present, a geared pump installed on a small trolley has been used. However, this was not at all satisfactory, because the gears of the pump were overloaded.

How to pump edible oils efficiently while complying with all hygiene regulations

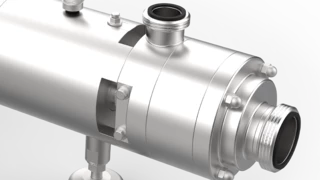

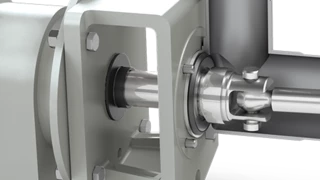

For the edible oil manufacturer, the solution to all his problems in pumping edible fat and oil was: The TORNADO® T.Sano®rotary lobe pump with smooth surface from NETZSCH. To reduce the high level of wear and tear and the resulting large amount of maintenance, he converted his system from a gear pump to a mobile rotary lobe pump. The T.Sano® offers a unique advantage thanks to its innovative drive technology. Instead of the standard but very complex and heavy synchronous gear, this model series uses a belt drive. The flexibility required by the oil manufacturer is thus given in every application. In addition, the belt drive simplifies any maintenance measures and does not require lubrication. This considerably reduces your maintenance costs. Thanks to the continuous hard-soft contact between the drive, belt and shafts, smooth running is also achieved, which protects the components.

In order to reduce the high wear and, thus, the resulting frequent maintenance, the system was changed last year to a mobile TORNADO® T.Sano rotary lobe pump. However, for the design of the pump, the particular characteristics of the edible oil must also be taken into consideration. In another plant, the centrifugal pumps used would have shattered the oil into droplets. Pulsation can cause a problem for rotary lobe pumps, too. Thus, in order to reduce this, multiple bladed lobes are usually used for sensitive products. In contrast, NETZSCH relies on the special design of the delivery chamber of the TORNADO® T2 series. Small pockets, machined into the inner wall, make sure that the material can smoothly flow into the delivery chamber. The pulsation of the two-bladed lobe thereby remains at the level of a four-bladed lobe, so that the edible oil can be filled without changing its consistency. So that the pump system, together with all the accessories, can be easily used and moved between the filling positions, a compact construction and low weight were important factors.

Due to its innovative drive technology, the T.Sano® has a specific advantage: Instead of the usual, but very complex and heavy timing gear, a much lighter belt drive is used for this series. Thus, the flexibility required by the manufacturer is assured in all application situations. In addition, the belt drive simplifies any maintenance tasks and requires no lubrication. Due to the continuous hard-soft contact between drive, belt and shafts, a high level of smooth running is attained, which protects the components in general. The T.Sano® fulfills the delivery function to the complete satisfaction of the oil producer.

TORNADO® T.Sano® rotary lobe pump with smooth surface

- Medium: Edible fad and oil

- Capacity: 27 m³/h

- Speed: Between 150 and 440 rpm

- Pressure: 4 bar