Yoghurt

How to Increase Your Efficiency When Pumping Yoghurt

Gentle yoghurt pumping while maintaining the highest hygiene standards

When pumping yoghurt, are high efficiency and the highest hygiene standards simultaneously conflicting for you? That's precisely what one of the largest dairy plants thought until it became aware of the products from NETZSCH Pumps & Systems.

As a global specialist in complex fluid management, NETZSCH Pumps & Systems offers innovative solutions for the food sector. Discover how to benefit and increase your efficiency when pumping yoghurt.

Individual Consulting

Pumping yoghurt: These are the challenges to overcome

Yoghurt is one of the most demanding conveyed media in the food sector. Gentle processing is crucial in producing numerous types of yoghurt to maintain its characteristic consistency. Pump technology plays a vital role. Most common pumps quickly reach their limits when pumping yoghurt. Due to their design, shear forces often occur, which dilute the yoghurt. To maintain the product quality, expensive proteins sometimes have to be added to the yoghurt afterwards. This significantly increases production costs. Another challenge in pumping yoghurt, like all dairy products, is the extremely high hygiene standards. Since even the slightest impurities can render entire batches unusable, the demands on yoghurt pumps are incredibly high.

How to meet the highest quality standards when pumping yoghurt

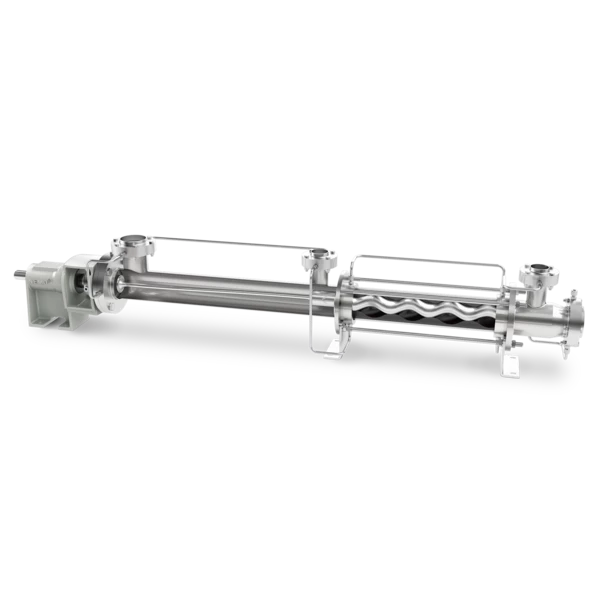

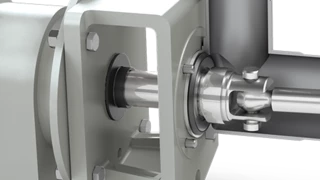

All materials must be food-safe, and time-intensive cleaning must be executed to meet the high-quality standards and the associated requirements for pumping yoghurt. Therefore, in the NEMO® SA aseptic pump in bearing bracket design from NETZSCH, a flexible rod connects the drive to the shaft instead of open or oil-filled joints. This is shrunk to the rotor and the connection point. Thus the transition remains hermetically sealed, which prevents the entry of impurities. Since no components rub against each other during the connection, the flexible rod hardly wears out. As a result, you only have to deal with low maintenance costs. Stainless steel was used for the application in the dairy plant. Parts that come into contact with the product, such as the rotor, are even polished. In addition, a stator made of FDA-compliant elastomer is used. Furthermore, the mechanical seal is a double seal with a unique hygienic design on the product side. This offers you maximum product safety when pumping yoghurt and thus ensures the highest quality standards.

How to reduce your downtime when pumping yoghurt

Extensive cleaning is also necessary to maintain quality standards permanently. However, this often leads to long downtimes, resulting in high operating costs. Not with the NEMO® progressing cavity pumps, however. Thanks to the innovative design, the units offer you the CIP - "Cleaning-In-Place-Procedure" and the SIP - "Sterilisation-in-Place-Procedure" when pumping yoghurt. A bypass line and tangential rinsing nozzles ensure that the necessary flow speed of the cleaning fluid is achieved throughout the entire system. In addition, the delivery area's flow-optimised geometry prevents dead spaces and product build-up. It also enables comprehensive cleaning, including complete emptying of the pump. This means that nothing stands in the way of cleaning and even sterilising the pumps without removing them from the system. This reduces your downtime when pumping yoghurt and saves you time and money.

To compensate for any fluctuations in the flow rate, the pump was combined with a variable speed gearbox and a frequency converter. This allows the system to pump up to 20 m³ of yoghurt per hour at ten bar in continuous operation without malfunctions and impairing quality. Switch to a NEMO® progressing cavity pump and increase your efficiency when pumping yoghurt.

NEMO® SA aseptic pump with bearing housing

- Medium: Yoghurt

- Throughput volume: 20 m³/h

- Presssure: 10 bar