Especially in the chemical industry, process reliability plays a central role. The PERIPRO® hose pump in chemical design offers you the highest reliability even in conveying corrosive products with maximum metering accuracy at the same time.

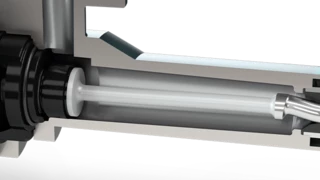

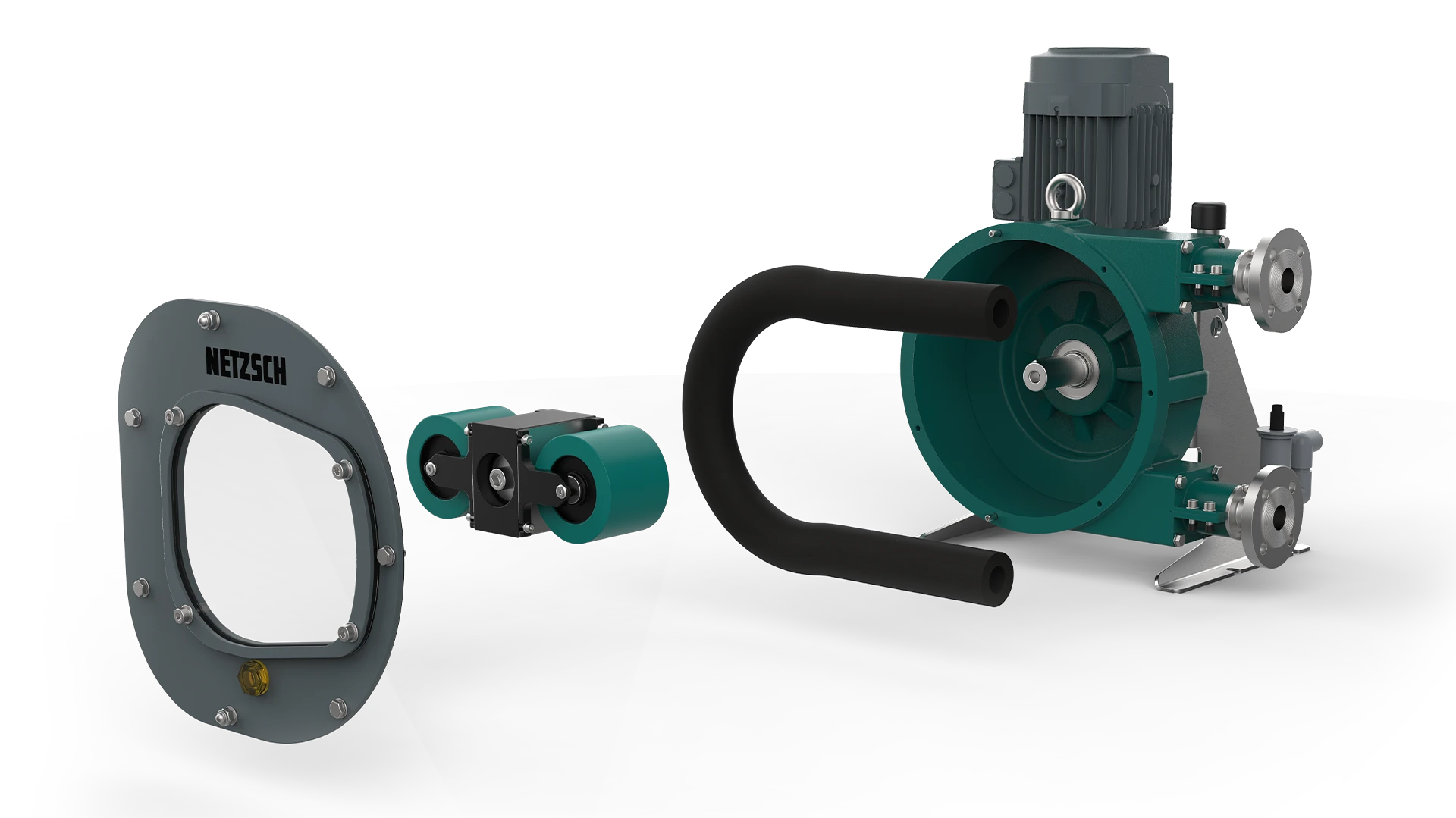

The challenges of the products to be conveyed in the chemical industry could not be more varied. The numerous different materials of the hose enable you to transfer even corrosive products safely. With the PERIPRO® hose pump in chemical design, you can convey and meter, for example, corrosive products such as hydrochloric acid, sulphuric acid or ferric chloride in compliance with the highest safety standards. The metering accuracy of the hose pumps is particularly high, with a deviation of less than one percent. In order to ensure maximum safety and easy maintenance, the wear parts of the hose pumps have been reduced to an absolute minimum. PERIPRO® pumps have no mechanical seals or valves and require only small amounts of lubricant. Therefore, the peristaltic pumps are particularly easy to service and optimally suited for continuous operation. The large corrosion-resistant rollers also increase the service life of the hose. This significantly reduces your downtime and service times. Hence, you save both time and money. Nothing stands in the way of safe as well as continuous conveying and metering of your products in the chemical industry.

Safe as well as continuous conveying and metering of your products

In order to ensure maximum safety and easy maintenance, the wear parts of the hose pumps have been reduced to an absolute minimum. PERIPRO® pumps have no mechanical seals or valves and require only small amounts of lubricant. Therefore, the peristaltic pumps are particularly easy to service and optimally suited for continuous operation. The large corrosion-resistant rollers also increase the service life of the hose. This significantly reduces your downtime and service times. Hence, you save both time and money. Nothing stands in the way of safe as well as continuous conveying and dosing of your products in the chemical industry.

Individual Consulting

Advantages

Easy maintenance

No mechanical seals

Capacity

Technique

Worldwide service and support for your pump and system

Our service and support do not end with the purchase. From consultation, spare parts and maintenance to the repair and modernization of your pump - we support you right from the start.

Thanks to our worldwide service network, we are ready for you around the clock in case of an emergency.

Your contacts and companies at NETZSCH

Any specific questions? Contact us for help or fill in the contact form.