condensed milk

How to Pump Condensed Milk Maintenance-Free

Pumping condensed milk hygienically without wear and tear and lubrication

Do you operate a dairy, or are you planning one? If so, you are probably frustrated daily by the high wear and tear and escalating maintenance costs when pumping condensed milk. This was precisely the case for a dairy company in Wisconsin, a state in the United States of America until they came across NETZSCH Pumps & Systems.

Because the global specialist in complex fluid management has provided a solution with its innovative pump solutions, we will also show you how you can benefit from using a NEMO®progressing cavity pump for pumping sweetened condensed milk.

Individual Consulting

These challenges await you when pumping condensed milk

The Wisconsin-based dairy company specialises in producing liquid concentrated and frozen milk mix products. The company is one of the largest producers of its kind in the Midwest USA and the largest producer of condensed milk in the country. In addition, the company produces a range of specific milk mix products, such as cream liqueur and other individual drink preparations. Condensed milk, in particular, poses significant challenges for pumps due to its composition. In the production of sweetened condensed milk, the water content is reduced, and up to 45 per cent sugar is added. The result is a highly concentrated mixture of milk and sugar. This usually leads to very high wear on the condensed milk pumps because the medium attacks the material of the pumps and thus wears them out quickly.

Pumping condensed milk: How to increase your service life and reduce costs

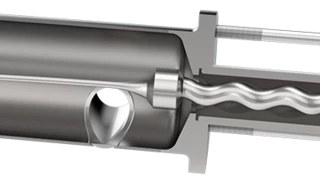

In production, there is a critical application near the end of the process where the milk-sugar mixture has to be pumped out of two flash coolers under a vacuum. Previously, the company relied on other condensed milk pumps, but within a short time, the metal surfaces wore out. Other systems tested over the years could have been better. Finally, the dairy company turned to NETZSCH. The engineers recommended using a NEMO® progressing cavity pump with a flexible rod. Thanks to the flexible shaft, no moving parts rub against each other in the progressing cavity pump, significantly reducing wear due to the abrasive medium. As a result, the pump offers a particularly long service life when pumping condensed milk without lubrication. This significantly reduces your maintenance and servicing costs.

Since the pumps were installed, they have been running continuously seven days a week at the Wisconsin dairy with no maintenance or performance problems. After a few months, one pump was disassembled to see if the stator or other parts showed wear, but there were no signs. Upgrade your plant to a NEMO® progressing cavity pump with a flexible rod and stop worrying about high wear and expending maintenance costs when pumping condensed milk.

How to prevent contamination when pumping condensed milk

Since the patented design with flexible rod also has no gaps and dead areas, it is often used for producing food, pharmaceuticals, cosmetics, and chemical or biochemical applications. The design also offers you effortless cleaning (CIP - "Cleaning-In-Place-Process") and sterilisation (SIP - "Sterilisation-in-Place-Process"). This means that nothing stands in the way of cleaning and even sterilising the pumps without removing them from the system. As a result, you reduce your downtime when pumping yoghurt and save time and money. Without wear and lubrication, there is also no risk of product contamination. This is particularly important in process applications where pumping equipment must be very reliable due to continuous production in batches. The bending rod from NETZSCH is made of special steel and designed for up to ten million load changes. This steel guarantees the necessary stability to transmit the required drive torque and yet is sufficiently flexible to withstand the eccentric movement of the rotor. Another advantage this material offers you is its resistance to most chemical compounds.

NEMO® SH Plus hygienic pump with bearing housing

- Medium: Sweetened condensed milk

- Throughput volume: 9.0 m³/h

- Rotations speed: 158 rpm

- Pressure: 10.3 bar

- Viscosity: 1500 to 5000 cP