critical media

How to Pump Critical Media With Maximum Food Safety

Preventing health hazards thanks to NETZSCH pumps

Almost daily, we receive reports of recalls due to contaminated food, and the number of unreported cases is much higher. One reason for this is often attempted contamination through the abrasion of elastomers. But what can you do to avoid it?

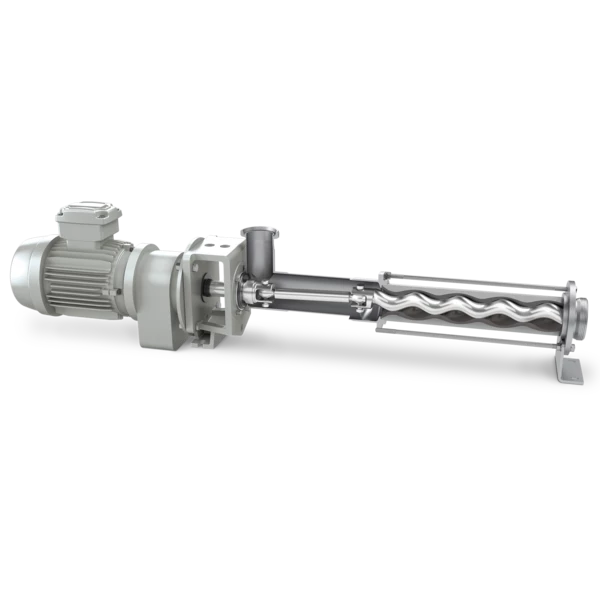

We will show you how to prevent future contamination through abrasion when pumping critical media in the food industry. As a global specialist in complex fluid management, NETZSCH Pumps & Systems offers you NEMO® hygienic progressing cavity pumps specially optimised for the food industry. This allows you to pump even critical media in compliance with the highest hygiene regulations.

Individual Consulting

Dangers when pumping critical media in the food industry

In the food manufacturing industry, there is a wide range of media with complex consistencies and sometimes high viscosities that must be handled very sensitively. These include honey, molasses, brewer's grains and chocolate. Despite many advantages of taking the so-called critical media, progressing cavity pumps have the reputation of being only conditionally suitable for product-contacting tasks in the food industry. The fear concerns latent contamination of the foodstuffs due to abrasion of the elastomers triggered by the medium. When pumping critical press, even the slightest contamination can destroy the product and thus cause enormous costs, not to mention the danger to the consumer.

How to pump even abrasive and critical media food safe

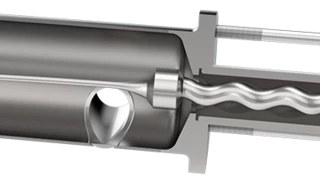

Indeed, essential components of progressing cavity pumps such as stators and seals are mainly made of elastomers, elastic natural or synthetic rubber. Depending on the pumped medium, wear occurs due to the friction between the rotor and the stator elastomer. This is particularly the case with very abrasive media, which appear relatively rarely in the food sector. NETZSCH offers you the optimal pump solution even for critical media. NEMO® hygienic progressing cavity pumps are designed to ensure that abrasion is negligible when used correctly. This way, you can prevent health hazards for consumers and high costs due to contamination when pumping critical media. In an internal risk assessment, the rubber abrasion caused by wear when pumping critical media was compared with the total flow rate to be expected during the entire operating life of the stator. The result: The calculated value is in the single-digit ppb range. The abbreviation ppb stands for "parts per billion", a dimensionless concentration specification often used in residue analytics and indicates how many weight or volume units of a substance are contained in one billion units of another meaning. The entry of the elastomers is, therefore, negligibly small. Thus, when pumping critical media, you can rule out an unacceptable change in the composition of the pumped material due to abrasion. In addition, only elastomers suitable for foodstuffs are used at NETZSCH.

How to pump critical media in compliance with all hygiene regulations

The hygienic progressing cavity pumps from NETZSCH, specially developed for the food sector, fulfil the regulations and specifications of several international regulators. First are the American Food and Drug Administration (FDA), the European Hygienic Engineering and Design Group (EHEDG) and the 3-A Sanitary Standard. This means you can pump even critical foodstuffs in compliance with the highest hygiene regulations. At the heart of all these regulations is the food-safe nature of the materials used and the ability to clean the design. Conventional progressing cavity pumps have been adapted for use in hygienically sensitive areas.

To ensure you can use progressing cavity pumps safely in the food sector, the elastomer used, for example, is specially designed for contact with food. Therefore, only those compositions selected for the food sector that has good wear resistance on the one hand. On the other hand, they fully comply with all food safety regulations of American and European authorities, such as the EU Regulation 1935/2004. This means, by using a NETZSCH pump, you exclude any potential health risk to consumers according to the current state of the science.

NEMO® BH hygienic pump in compact block design

- Medium: Honey, molasses, brewer's grains or chocolate and many more

- Pressure: Max. 24 bar

- Flow rate: Max. 120 m³/h

- Speed: Max. 800 rpm