WATER-COAL DUST MIXTURE

How to Pump Water-Coal Dust Mixture Efficiently in Opencast Mining

Opencast mining: With this pump, you optimise coal fine dust recovery

When coal is exploited in opencast mines, coal fine dust enters the water. To conserve resources and avoid environmental pollution caused by the mixture of water and coal dust, it must be decanted by a unique system afterwards. Until now, an Australian company used centrifugal pumps for this purpose. However, they did not deliver with the desired efficiency.

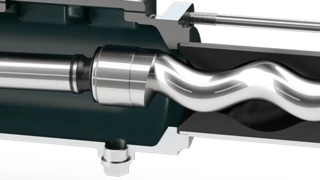

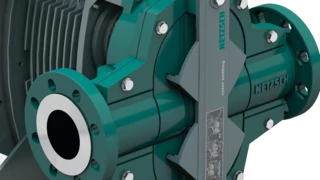

In the mining industry, TORNADO® T1 rotary lobe pumps ensures optimum decantation of water during coal fines recovery.

Compared to the centrifugal pumps frequently used, rotary lobe pumps not only have a higher efficiency but also enable more precise metering.

Individual Consulting

Environmental protection thanks to an efficient water-coal dust mixture pump

In Australian open-pit mining, fine coal dust is extracted from water-coal dust mixture with a temperature of 25 °C. "For this purpose, the mixture is first fed to horizontal belt filters", says Steve Weir, Business Development Manager at NETZSCH Australia Pty Ltd. Until August 2017, two centrifugal pumps were used for decanting the excess water. However, these pumps were not ideal. For example, they had a high NPSHr value, which meant that the intended flow rates could not be met with precision. "Cavitation's, or gas-filled bubbles, frequently develop in centrifugal pumps. They not only reduce the efficiency of the system, but make accurate metering impossible", says Weir. "This, in turn, limited the throughput of the system." The management, therefore, decided to replace the pumps with other models, which were expected to discharge process water with more precision, reliability and efficiency.

Challenges in pumping water-coal dust mixture

The essential requirement for the new units was their suitability for pumping product containing solid matter. They also needed to feature flow rate of 240 m³/h, pressure of three bar, and NPSHr of 1.8 m. Finally, the management selected two rotary lobe pumps of the NETZSCH TORNADO® T1 series in size XLB-6/2. These pumps not only meet the requirements of the open-pit operator in terms of flow rate, pressure, delivery rate and suction; they also have exceptionally convenient dimensions. The key advantage of the two TORNADO® T1 models over the previous system is that the NETZSCH models are self-priming positive-displacement pumps, which guarantee continuous delivery.

High efficiency and precise metering: This pump makes it possible

The essential requirements for the new water-coal dust mixture pumps included suitability for pumping media with solids, a flow rate of 240 m³/h, a pressure of three bar and an NPSHr value of 1.8 m. For this reason, the experts from NETZSCH recommended the use of TORNADO® T1 rotary lobe pumps. These meet the requirements of the open pit mine operator regarding flow rate, pressure, delivery capacity and suction conditions and also offer favorable and compact dimensions. The decisive advantage of the TORNADO® T1 over the previous system, however, is that the two self-priming positive displacement pumps ensure continuous precise delivery.

Since August 2017, the TORNADO® T1 rotary lobe pumps have been used at the Australian open-cast miner for pumping the water-coal dust mixture, decanting the excess water from the vacuum tank and conveying it to the clarifier or thickener. There, the water is recovered and reused in the coal preparation plant. Using the two frequency inverter-controlled pumps, a stable, lower liquid level is now achieved in the vacuum receiver, allowing you to operate it with a larger vacuum space. The higher vacuum and more consistent vacuum level result in better efficiency in coal fines recovery.

Upgrade your decanting system for water-coal dust mixture in opencast mining to a TORNADO® T1 rotary lobe pump and make a small contribution to resource conservation and environmental protection.

TORNADO® T1 rotary lobe pump

- Medium: Water-coal dust mixture

- Speed: 218 rpm

- Throughput volume: 240 m³/h

- Temperature: 25 °C

- Pressure: 3 bar

- Viscosity: 5 mPas

- NPSHr: 1.8 m