Maritime Applications

Efficient Pumps for Maritime Applications on Ships and in Ports

A wide variety of highly viscous and contaminated products in maritime applications

NEMO® progressing cavity pumps, TORNADO® rotary lobe pumps and grinding systems are used on ships and in harbors for conveying a wide variety of products.

Especially when pumps are used in shipping, the technology must meet special requirements.

Individual Consulting

Things to consider: Challenges for pumps in maritime applications

The challenges for pumps in maritime applications are as varied as their use cases. One of the most essential requirements for marine pumps is their resistance to salt water. As they are exposed to the aggressive influence of seawater, pumps in maritime applications must be made of corrosion-resistant materials such as stainless steel. This is the only way to ensure a long service life. In addition, marine pumps must withstand vibrations and shocks caused by the ship’s operation and the sea state. Robust designs and possibly vibration dampers or unique mounting systems are required to minimise these stresses’ effects and protect the pumps from damage. Another important aspect is the adaptability of the pumps to different operating conditions. On ships, fluid viscosities, pressures and temperatures can vary greatly. The pumps must cope with this variability and deliver reliable performance regardless of the operating conditions. Energy efficiency is also increasingly important. Energy consumption plays a crucial role in maritime applications regarding operating costs and environmental footprint. Therefore, pumps must be designed to be energy efficient and minimise energy consumption without compromising performance. In addition, marine pumps must be easy to maintain, as access to the pumps is often restricted due to limited space. They should be easy to maintain and repair without extensive disassembly work. Marine pumps must be carefully selected, installed and maintained to meet these challenges. This is the only way to ensure that they can withstand the specific demands of maritime operations and provide reliable performance over a long period.

Everything from a single source: NETZSCH pumps in all maritime applications

NETZSCH Pumpen & Systeme GmbH has developed different pump types, which can be universally deployed as transfer and booster pumps on ships and wharves, as well as on offshore platforms – to cover the full range of requirements in the maritime sector, from fuel or sludge transport, through loading and unloading, to stripping. NEMO®progressing cavity pumps, which cope particularly well with highly viscous products thanks to their special conveying principle, are therefore suitable for oil sludge or wastewater. The more compact TORNADO®rotary lobe pumps, which enable a higher flow rate, are for instance used to transfer wastewater, as well as to load and unload various products. The pumps can also be supplemented by macerators for the grinding and separation of larger, harder objects, primarily when conveying wastewater.

Thanks to their special design, NEMO® progressing cavity pumps can also cope with liquid media which contain solids, which means they are frequently used on passenger and container ships to convey wastewater. The pumps are based on a rotor that turns in an oscillating motion within a fixed stator that is geometrically adapted to it. The precise geometrical mating forms conveying chambers during rotation which transport the medium smoothly from the inlet to the discharge side. Because the chambers are self-sealing, this not only prevents backflow, but also ensures that the conveyed product is transported at stable volume and pressure, so that no shear forces and hardly any pulsation occur. With this displacement technology, the consistency, and especially the viscosity, of the product are insignificant in terms of the product flow. This is why the NEMO® pumps, which have a capacity of up to 400 m³/h, are not only used for wastewater, but also for pumping products, including oil residues and sludge, on oil tankers and cargo ships and even mixtures of oil, gas and sand on offshore platforms. In the process, the quantity transported is determined solely by the speed and can therefore be continuously and very precisely controlled with a metering accuracy of three to five percent. This enables the quantity required in each case to be metered directly from the supply line or the barrel. The progressing cavity pumps are also suitable for stripping and cleaning oil tanks on wharves.

In addition, a grinder which grinds and separates hard and heavy particles, can also be used for wastewater. It is installed in the wastewater circuit upstream from the pumps and thus prevents clogging or blocking due to solid contents, because it is even capable of chopping up fibre entanglements. The grinder also prevents the blocking of pipelines and further downstream equipment, and is used on passenger ships in particular.

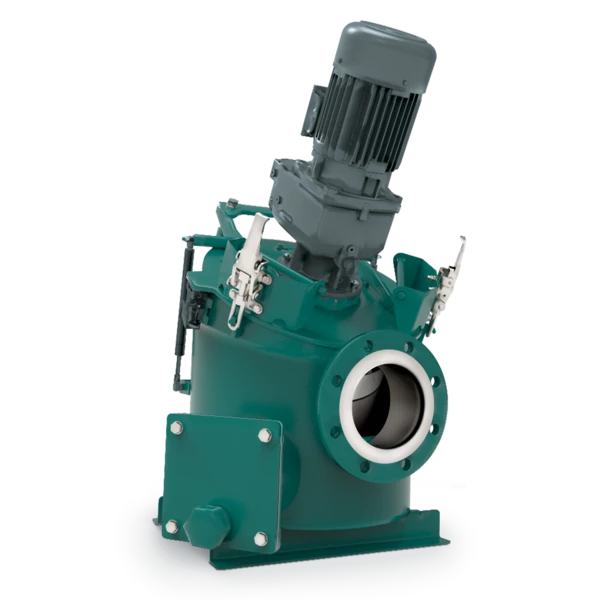

When space is limited, especially on ships, another type of pump, the TORNADO®rotary lobe pump, is ideal for the maritime sector, as it has a particularly compact design, while at the same time ensuring a high flow rate. The displacement element in these pumps consists of two rotary lobes that rotate in opposite directions, thus transporting the products smoothly but continuously. The delivery rate is also independent of the viscosity of the product with this version. The TORNADO® T2 type pumps in particular are specifically designed for the demands of use on the high seas: they not only take into account the limited space available on board, but also reduce expenditure on spare part stock and maintenance. Instead of a complex and bulky timing gear, the aggregate has an oil-free synchronized gear with belt drive which reduces the weight of the pump by at least 30 percent and ensures a very small installation depth. In addition, the whole mechanism is less susceptible to faults, which means the range of spare parts can be kept very low.

Maritime applications: This is how to benefit from the use of NETZSCH pumps

If you want to pump solids-laden liquids such as wastewater, then the NEMO® progressing cavity pump is the right choice. Progressing cavity pumps have been used on countless passenger and container ships for decades to pump wastewater effectively. The pump design prevents backflow of the medium and, simultaneously, offers you a volume- and pressure-stable movement of the pumped material. This means that hardly any gravitational forces and pulsation occur. Since the medium's consistency and viscosity are irrelevant to the flow rate, NEMO® pumps are not only used for wastewater. On oil tankers and cargo ships, they pump oil residues, oil sludge, and on offshore platforms, even oil-gas-sand mixtures. The progressing cavity pumps enable you to achieve up to 400 m³/h capacities. Furthermore, they are also suitable for stripping and cleaning shipyard oil tanks.

NEMO® BY progressing cavity pump, TORNADO® T. Envi® rotary lobe pump, M-Ovas® universal cutting plate macerator

- Capacity: NEMO® up to 400 m³/h, TORNADO® up to 1000 m³/h

- Media: Oil residues and sludge, mixtures of oil, gas and sand, industrial oil, multiphase mixtures, drill cuttings and drilling sludge

- Grinding: Blockages, clogging, fiber entanglements

- Metering accuracy: 3-5 %