condensed milk

How to Pump Condensed Milk Maintenance-Free

Pumping condensed milk hygienically without wear and tear and lubrication

Do you operate a dairy, or are you planning one? If so, you are probably frustrated daily by the high wear and tear and escalating maintenance costs when pumping condensed milk. This was precisely the case for a dairy company in Wisconsin, a state in the United States of America until they came across NETZSCH Pumps & Systems.

Individual Consulting

Dairy

Milk production is over 6000 years old, so it is no surprise that milk and dairy products have come to play an important role in our daily dietary preferences. It is also no surprise that innovations and structural changes in the large milk-producing countries not only have reduced delivery frequency from twice daily to every second or third day but have also improved the end product itself. Raw milk requires sanitary handling and additional processing to ensure that the milk and its derivatives suffer no loss in quality between the barnyard and the supermarket.

The predominant consideration when designing handling systems for this industry is to ensure the quality of the end products. Because of the flow behavior characteristics, products like yogurt, cream or pudding, for example, can be ruined as a result of improper handling and conveying.

At NETZSCH, years of experience in the design and manufacture of pumps for the dairy industry has yielded variety of pumping solutions to meet the specific processing needs and rigorous sanitary requirements associated with these products. NEMO® Progressing Cavity Pumps are able to gently convey products of high viscosity - with or without solid content - in an almost pulsation-free manner. Crevice-free construction and polished surfaces make our Sanitary and Aseptic Pumps capable of meeting the demanding hygienic standards of leading dairy companies. In addition, these pumps are designed with CIP (cleaning-in-place) or sterilized with steam SIP (sterilization-in-place) ports for easy cleaning. Contact us and we will be happy to provide a solution for your application!

How to prevent contamination when pumping condensed milk

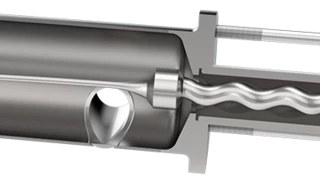

Since the patented design with flexible rod also has no gaps and dead areas, it is often used for producing food, pharmaceuticals, cosmetics, and chemical or biochemical applications. The design also offers you effortless cleaning (CIP - "Cleaning-In-Place-Process") and sterilisation (SIP - "Sterilisation-in-Place-Process"). This means that nothing stands in the way of cleaning and even sterilising the pumps without removing them from the system. As a result, you reduce your downtime when pumping yoghurt and save time and money. Without wear and lubrication, there is also no risk of product contamination. This is particularly important in process applications where pumping equipment must be very reliable due to continuous production in batches. The bending rod from NETZSCH is made of special steel and designed for up to ten million load changes. This steel guarantees the necessary stability to transmit the required drive torque and yet is sufficiently flexible to withstand the eccentric movement of the rotor. Another advantage this material offers you is its resistance to most chemical compounds.

NEMO® SH Plus hygienic pump with bearing housing

- Medium: Sweetened condensed milk

- Throughput volume: 9.0 m³/h

- Rotations speed: 158 rpm

- Pressure: 10.3 bar

- Viscosity: 1500 to 5000 cP