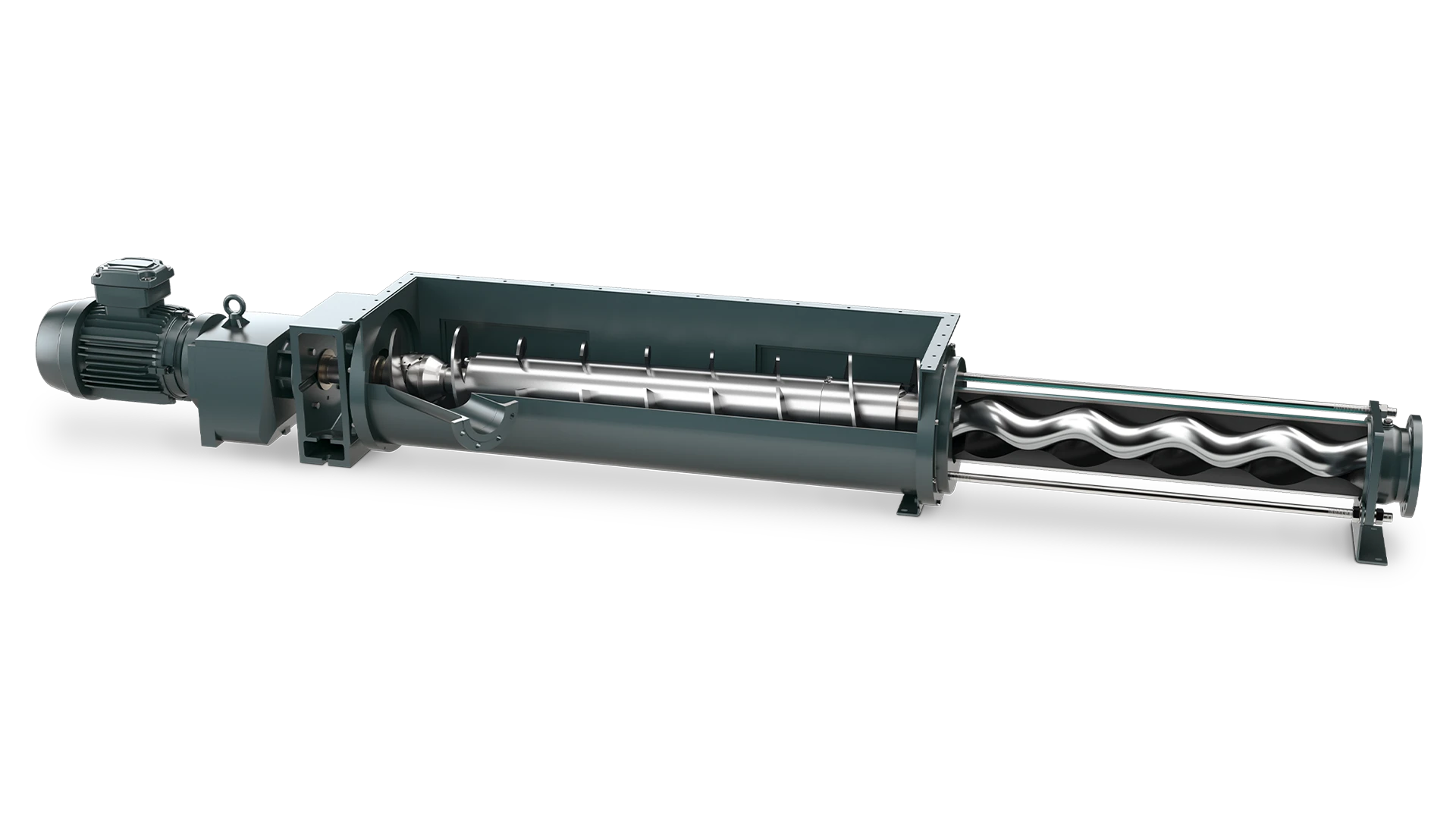

The NEMO® B.Max mixing pumps in block design with the directly flanged drive from NETZSCH set new standards in biogas and environmental technology through maximum mixing and conveyance of the media. It is the result of the continuous development of the NEMO®progressing cavity pump with a feed hopper and feeding screw.

Thanks to its pump housing with a large, rectangular feed hopper and removable, conically shaped stuffing chamber, as well as a coupling rod with a patented, position-optimized conveying screw, the progressing cavity pump guarantees optimal product feed into the conveying elements regardless of pressure and viscosity.

NEMO® B.Max mixing pump: Maximum mixing of substrates

The position-optimized tangential inlet on the hopper housing facilitates maximum mixing of the substrates. The B.Max mixing pump is particularly suitable for continuous and low-pulsation conveying of fermented renewable raw materials, liquid manure, process water, ground biowaste, food waste, pre-processed slaughterhouse waste, concentrated substrates, thickened substrates, and slop.

Individual Consulting

Mixing Pumps Advantages

Gas

Pressure

Safety

NEMO B.Max Mixing Pump Technique

Worldwide service and support for NEMO B.Max Mixing Pump

Our NEMO B.Max Mixing Pump service and support do not end with the purchase. From consultation, spare parts, and maintenance to the repair and modernization of your pump - we support you right from the start.

Thanks to our worldwide service network, we are ready for you around the clock in case of an emergency.

Your contacts and companies at NETZSCH

Any specific questions? Contact us for help or fill in the contact form.