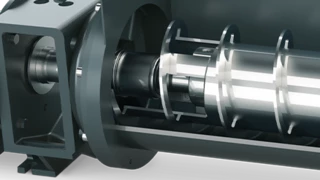

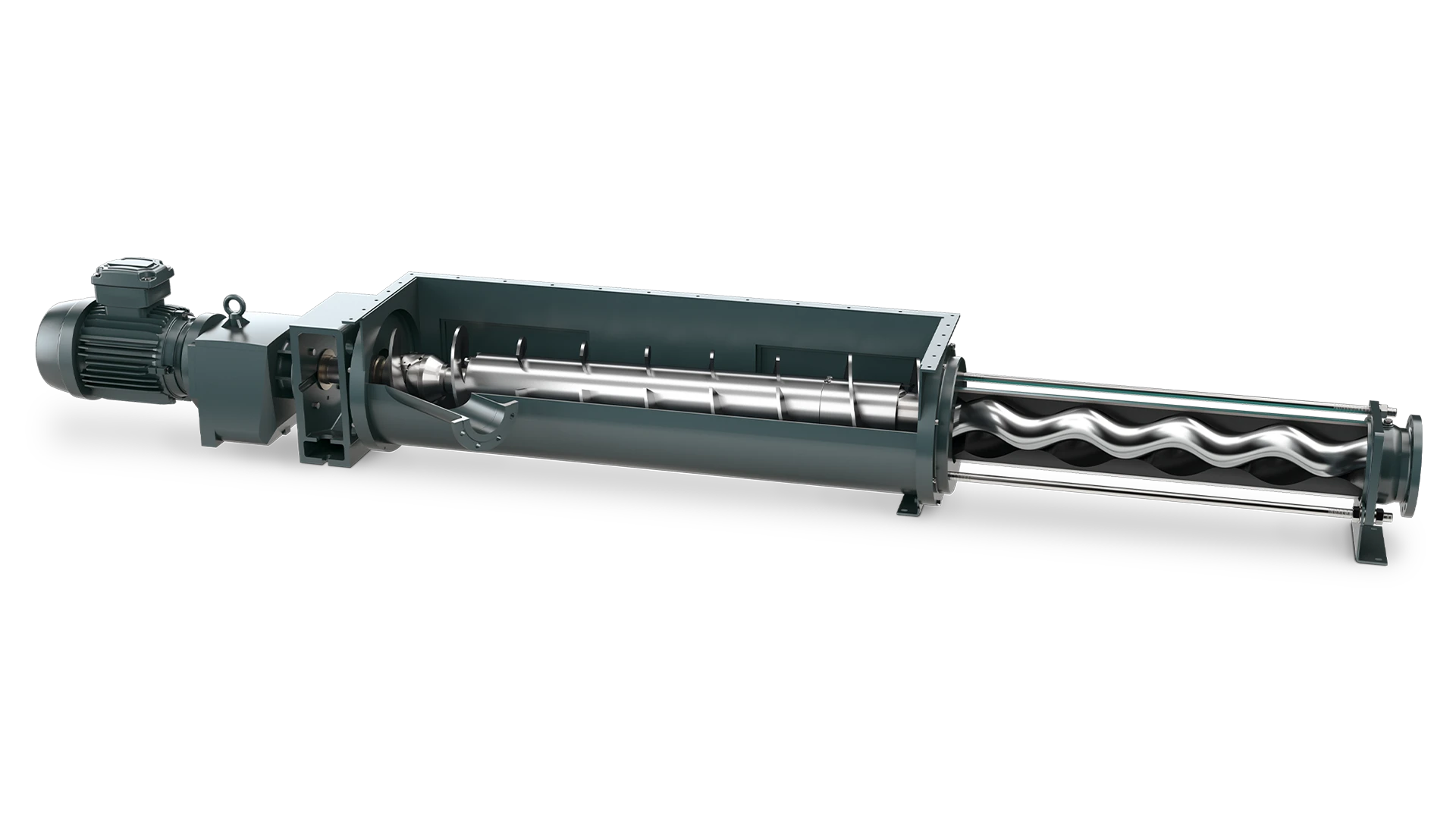

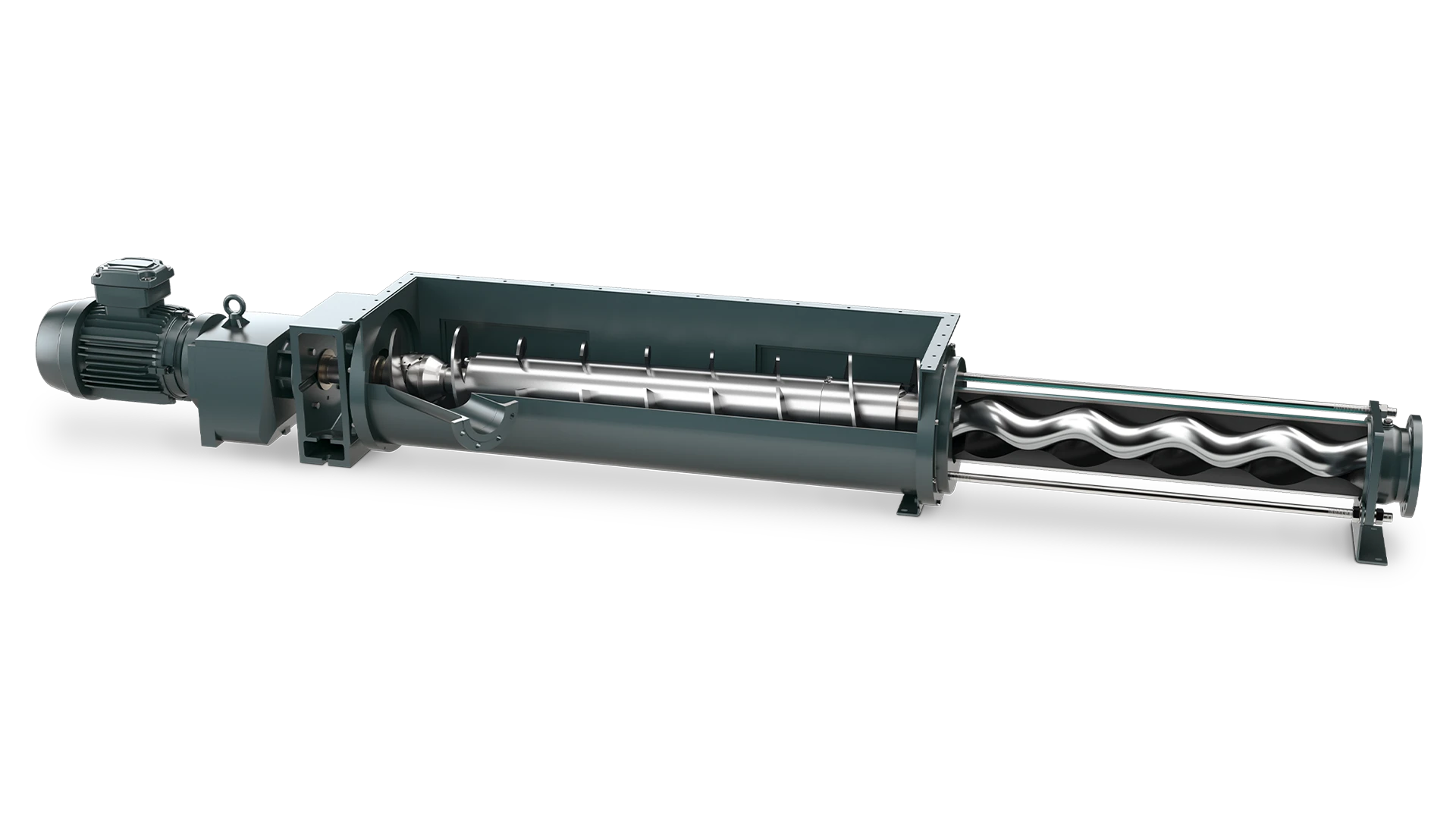

The pump housing has a large rectangular hopper and removable conical force-feed chamber, as well as a coupling rod with patented, horizontally positioned conveying screw, that guarantee optimal product feeding to the conveying elements. The positioning of the conveying supports on the hopper housing allows for maximum mixing of the substrate.

The NEMO® B.Max is particularly well-suited for the following substances:

- Fermented NAWARO

- Liquid manure

- Process water

- Ground bio-waste and food waste

- Preprocessed slaughterhouse waste

- Cosubstrates

- Concentrated substrates

- Slop

Advantages of the NEMO® B.Max hopper-shaped progressing cavity pump:

- Maximum homogenization of the substrate

- Increased gas production

continuous low-pulsation conveyance independent of pressure and viscosity - High pressure capability

- Robust drive seals

- Low investment and operating costs

- High operating safety

- Reinforced screw

Everything from a Single Supplier: To accommodate the various applications in your processes, it is now also possible to procure NEMO® progressing cavity pumps together with the well-known NETZSCH TORNADO®industrial rotary lobe pumps. Take advantage of our decades of experience and know-how in the manufacturing of positive-displacement pumps.

NEMO® B.Max mixing pump: Maximum mixing of substrates

The position-optimized tangential inlet on the hopper housing facilitates maximum mixing of the substrates. The B.Max is particularly suitable for continuous and low-pulsation conveying of fermented renewable raw materials, liquid manure, process water, ground bio-waste, food waste, pre-processed slaughterhouse waste, concentrated substrates, thickened substrate and slop.

Individual Consulting

Advantages

Gas

Pressure

Safety

Technique

Worldwide service and support for your pump and system

Our service and support do not end with the purchase. From consultation, spare parts and maintenance to the repair and modernization of your pump - we support you right from the start.

Utilizing our worldwide service network, we are ready for you around the clock in case of an emergency.

Literature

- NEMO® Progressing Cavity PumpsBrochure

- NEMO® BO Hopper Pump with Cutting DeviceFlyer

- BiogasBrochure

- MultiProtector: The Monitoring and Protection UnitBrochure

- Lithium Battery ManufacturingBrochure

- Wastewater TreatmentBrochure

- aBP-Module®Brochure

- SH Sanitary Advanced Plus PumpFlyer

- BH Sanitary Advanced Open Hopper PumpFlyer

- BY Sanitary Prime PumpFlyer

- BO Sanitary Prime Open Hopper PumpFlyer

- Independent ControlsBrochure

- Customer Service/AftermarketBrochure

Your contacts and companies at NETZSCH

Any specific questions? Contact us for help or fill in the contact form.

News from NETZSCH Pumps & Systems

The pump housing has a large rectangular hopper and removable conical force-feed chamber, as well as a coupling rod with patented, horizontally positioned conveying screw, that guarantee optimal product feeding to the conveying elements. The positioning of the conveying supports on the hopper housing allows for maximum mixing of the substrate.

The NEMO® B.Max is particularly well-suited for the following substances:

- Fermented NAWARO

- Liquid manure

- Process water

- Ground bio-waste and food waste

- Preprocessed slaughterhouse waste

- Cosubstrates

- Concentrated substrates

- Slop

Advantages of the NEMO® B.Max hopper-shaped progressing cavity pump:

- Maximum homogenization of the substrate

- Increased gas production

continuous low-pulsation conveyance independent of pressure and viscosity - High pressure capability

- Robust drive seals

- Low investment and operating costs

- High operating safety

- Reinforced screw

Everything from a Single Supplier: To accommodate the various applications in your processes, it is now also possible to procure NEMO® progressing cavity pumps together with the well-known NETZSCH TORNADO®industrial rotary lobe pumps. Take advantage of our decades of experience and know-how in the manufacturing of positive-displacement pumps.

NEMO® B.Max mixing pump: Maximum mixing of substrates

The position-optimized tangential inlet on the hopper housing facilitates maximum mixing of the substrates. The B.Max is particularly suitable for continuous and low-pulsation conveying of fermented renewable raw materials, liquid manure, process water, ground bio-waste, food waste, pre-processed slaughterhouse waste, concentrated substrates, thickened substrate and slop.

Individual Consulting

Advantages

Gas

Pressure

Safety

Technique

Worldwide service and support for your pump and system

Our service and support do not end with the purchase. From consultation, spare parts and maintenance to the repair and modernization of your pump - we support you right from the start.

Utilizing our worldwide service network, we are ready for you around the clock in case of an emergency.

Literature

- NEMO® Progressing Cavity PumpsBrochure

- NEMO® BO Hopper Pump with Cutting DeviceFlyer

- BiogasBrochure

- MultiProtector: The Monitoring and Protection UnitBrochure

- Lithium Battery ManufacturingBrochure

- Wastewater TreatmentBrochure

- aBP-Module®Brochure

- SH Sanitary Advanced Plus PumpFlyer

- BH Sanitary Advanced Open Hopper PumpFlyer

- BY Sanitary Prime PumpFlyer

- BO Sanitary Prime Open Hopper PumpFlyer

- Independent ControlsBrochure

- Customer Service/AftermarketBrochure

Your contacts and companies at NETZSCH

Any specific questions? Contact us for help or fill in the contact form.