industrial waste water

How to Pump Abrasive Industrial Wastewater With Low Wear and Tear

TORNADO® T.Envi® rotary lobe pump facilitates industrial wastewater treatment

Global warming is causing water to become increasingly scarce worldwide due to persistent droughts, while consumption is rising steadily. This makes the thorough treatment of industrial wastewater all the more critical. However, the composition of industrial wastewater poses significant challenges for the pumps used.

As a global specialist in complex fluid management, NETZSCH Pumps & Systems offers you the optimal solution for low-wear pumping of abrasive industrial wastewater. Profit sustainably from the use of a service-friendly TORNADO® T.Envi® rotary lobe pump.

Individual Consulting

Pumps for the sustainable treatment of industrial wastewater

Used service water from industrial processes is one of the most problematic types of waste water due to its composition, which is often very demanding for conveying systems. In order to enable problem-free treatment of this kind of waste water in spite of this, the T.Envi® is specially designed for a long service life with minimum wear, so that it can also convey extremely abrasive product without any problem.

You don't want to change your industrial wastewater pump every six months?

For a long time, submersible gyroscopes were used to convey industrial wastewater in the building materials industry. However, the stones in the industrial wastewater and the abrasive sand ensured short service lives because of the high speed required and the associated high maintenance costs. Because of excessive abrasion and wear, the pumps could no longer be used meaningfully after only about six months. To enable trouble-free treatment of such wastewater, NETZSCH developed a special pump that can withstand a wide variety of product. The robust and powerful TORNADO® T.Envi® rotary lobe pump can significantly extend your service life when pumping industrial wastewater.

Wastewater treatment: Pump with minimum maintenance requirements

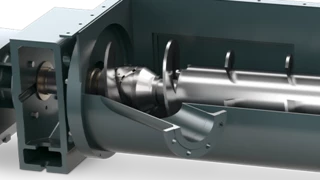

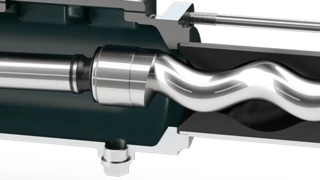

The TORNADO® rotary lobe pump, individually designed to meet the requirements of industrial wastewater, not only reduces the downtimes of your systems but also minimizes the maintenance effort. The basis for this is an innovative mix of materials. Instead of elastomer pistons in a metal housing, two hardened steel pistons rotate in an easily replaceable elastomer housing insert. As steel is less susceptible to material fatigue due to dynamic forces, more extended durability of the moving components is achieved. In addition, the metal expands less under the changing temperatures when pumping industrial wastewater, which is why tighter tolerances can be used in production, which is reflected in higher efficiency. The drive is a belt drive, which also synchronizes the shafts and pistons.

A T.Envi® from NETZSCH was used which is specially designed to be extremely robust and for a long service life with minimum maintenance effort. The reason for this is an innovative mixture of materials: instead of elastomer lobes rotating in a metal housing, this involves two hardened steel lobes rotating in a elastomer housing insert which is easy to replace. Steel is less susceptible to material fatigue due to dynamic forces – of the type that arise when there is repeated stress on the elastomer or plastic rotary lobes which are otherwise common – this means longer durability of the moving components is achieved.

In addition, there is less expansion of the metal with changing temperatures, thus allowing to work with lower tolerances in manufacturing which is reflected in higher efficiency. This has the added advantage that the pump can be run at a lower speed, which affords the components greater protection and reduces wear even more. Furthermore a belt drive is fitted which also ensures synchronizing of the shafts and lobes. This means the design has a minimum of parts, making it less susceptible to failures, simplifying maintenance and significantly reducing the required spare parts inventory in comparison to complex gear boxes. So far checks have shown hardly any wear, in spite of the mineral components in the waste water.

TORNADO® T.Envi® rotary lobe pump

- Product: Mineral waste water with pebbles up to 20 mm in diameter

- Pressure: 3 bar

- Conveying capacity: 18 m³/h

- Suction height: 3 mWS

- Riser: 10 m