SEWAGE WATER

Pumps for Desludging Highly Abrasive Sewage Water

Reduce operating costs by changing from centrifugal pump to rotary lobe pump

Do you want to reliably de-sludge your sewage water produced during water jet cutting, and are you tired of the short service lives of centrifugal pumps? As a global specialist in complex fluid management, NETZSCH Pumps & Systems offers solutions for pumping industrial sewage water individually tailored to your requirements.

We will show you how to reduce your operating costs sustainably by replacing your submersible centrifugal pump with a robust and powerful TORNADO® T.Envi® rotary lobe pump.

Individual Consulting

Sewage water pumps: Robust, long service life and easy maintenance

Sewage water occurs in almost all industrial operations and processes and is one of the most complex forms of wastewater. This is due, in particular, to the demanding composition of the pumps and conveying systems. The contents range from dissolved and undissolved, inorganic and organic substances to acidic and basic media, oils, and poisons. For example, the wastewater from waterjet cutting contains a high proportion of sand and is, therefore, particularly abrasive. This is because an abrasive cutting aid is added to the water. This is often fine garnet sand. After the cutting process, however, the water-sand mixture must be separated again so that the sand can be disposed of. Unique pumps are needed to remove and separate the sludge from the water. The focus of sewage water pumps is on robust and durable construction and high operational reliability. But easy maintenance also plays a significant role.

Sewage pumps: Replace centrifugal pump - reduce service times

Although the sand may be very useful as a cutting aid, it does lead to effort in terms of disposal. In order to relieve the burden on their customers in this area, the manufacturer offer an automatic removal system for their machines: The water-sand mixture is transported by pump to a cyclone which separates the solids from the water using centrifugal force and thus makes disposal easier. Because conventional pumps wear very quickly due to the abrasive product, the company is using the particularly robust TORNADO® T2 rotary lobe pumps made by NETZSCH Pumpen & Systeme GmbH. Their condition is almost as good as new, even after double the operating time in comparison to the previous centrifugal pumps.

How to double your service life when pumping sewage water

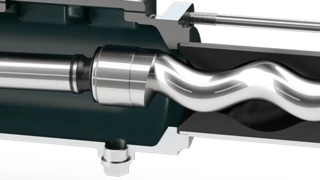

Despite the high abrasiveness of the sewage water, the TORNADO® T.Envi® rotary lobe pump offers you a particularly long service life. On the one hand, this is due to the robust and durable design and, on the other hand, to the material reversal. While other pump manufacturers usually have elastomer pistons rotating in a metal housing, this pump uses steel rotary pistons. The inside of the pump is lined with a rubber insert. This gives you a pumping capacity of 35 m³/h when pumping industrial sewage water.

In order to find an efficient and cost-effective solution, the manufacturer has therefore been testing the robust TORNADO® T.Envi® rotary lobe pump since the end of 2014. A characteristic feature of this type of pump is its combination of materials. Whereas other pump manufacturers normally have elastomer lobes rotating in a metal housing, steel rotary lobes are used here and the inside of the pump is lined with a rubber insert. For its tests, the water jet cutting expert used the T2, a version of the TORNADO® which has a pumping capacity of 35 m³/h. The final evaluation of the test pump was carried out after the device had circulated a total of 90 t of the sandy abrasive. It was not possible to detect any wear in the pump chamber on NETZSCH's T2, in spite of the long operating time. The insert and the mechanical seal were still in perfect condition. The shaft seals, including contact pressure and lubrication, also showed no damage or impairments. Only the rotary lobes showed slight traces of wear at the tips. The clearances still conformed to the dimensions at the time of delivery. Overall, the loss of pumping capacity due to these signs of wear was so small that it was possible to compensate for this without any problem by slightly increasing the speed. The rotary lobe pump continued to be used effectively, despite already having double the service life. For even greater improvement of service lives, which were already good, NETZSCH experts have further optimized various aspects of their TORNADO®pumps for standard use in water jet cutting systems and tailored them to the specific application conditions. The customers can in future fully concentrate on the demanding cutting process, with the removal of residual water and sludge taking care of itself.

TORNADO® T.Envi® rotary lobe pump

Product: Water-sand mixture

Pumping: 3 bar

Pumping capacity: 35 m³/h

- Product: Sewage water (water-sand mixture)

- Pressure: 3 bar

- Flow rate: 35 m³/h