FRUIT JUICE CONCENTRATES

Save Time and Money by Pumping Juice Concentrates Directly From Barrels

How to pump juice concentrates without residue and prevent contamination

Do you work in the food industry? If so, you have probably faced the challenge of pumping fruit juice concentrates or other liquids out of barrels and containers in compliance with the highest hygiene regulations.

As a global specialist in complex fluid management, NETZSCH Pumps & Systems offers you the optimal solution for pumping fruit juice concentrates and other media. We will show you how to pump your juices hygienically without residual volume directly from barrels in the future and thus save time and money.

Individual Consulting

Pumping fruit juice concentrates in compliance with the highest hygiene standards

Fruit juices and other beverages are generally easy to pump and thus cause hardly any problems in internal material logistics. Due to their good flow properties, they are easy to convey and transfer. However, this easy handling sometimes leads to hygienically critical actions. To get the product for further processing, the containers are often placed in a tilting device and thus emptied into a funnel above a pump. Clamping and sweeping the full barrels is very uncomfortable. Moreover, more than complete emptying of the containers is needed. Hygiene is even more problematic since, with this procedure, the product is transferred openly and is thus susceptible to foreign matter. NETZSCH has developed an innovative solution for pumping fruit juices directly from barrels or containers. Nothing stands in the way of compliance with the highest hygiene standards.

You want to pump fruit juice concentrates directly from barrels without residual quantity?

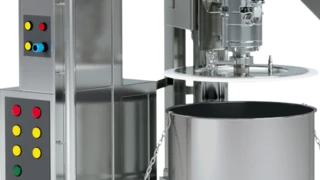

This is precisely where the barrel emptying systems from NETZSCH come into the picture. Due to its design, the barrel emptying system with NEMO® BH pump is self-priming and straightforward to clean. The innovative design allows you to pump fruit juices directly from barrels or containers without residual volume. By using the barrel emptying systems, you can prevent product loss. In addition, you save yourself the time-consuming task of cleaning the containers. This significantly increases your effectiveness when pumping fruit juices. By the way, you also contribute to reducing increasing food waste.

How to achieve maximum hygiene and effectiveness when pumping fruit juice concentrates

The barrel emptying system with NEMO® BH pump consists of a progressing cavity pump suspended vertically in frame construction and equipped with a follower plate at the suction nozzle. The plate size can be freely selected depending on the container to be emptied. It is surrounded by an elastomer sleeve so that it seals the drum airtight when it is lowered. This makes it impossible for foreign bodies to enter while pumping fruit juice concentrates.

To make this processing step simpler and safer, the company switched its filling lines from the tilting unit to the NBE 200 barrel emptying system from NETZSCH. The system consists of a progressing cavity pump hung vertically in a frame and fitted with a follower plate at the pump inlet. The size of the plate is tailored to the barrel to be emptied and is fitted with an elastomer sleeve so that it closes airtight to the barrel. When the pump is switched on, a vacuum forms and the barrel emptying system begins automatically to suck towards the floor. The light pressure exerted by the plate on the product prevents air pockets and ensures continuous conveying. Almost the entire volume can then be processed with only around one percent left in the barrel. A system with a flow of 11.6 m³/h at 188 rpm and maximum twelve bar pressure was installed for the fruit juice bottling systems manufacturer. The bottle filler can empty one barrel per minute leaving almost no residues – and thanks to the optional integrated roller conveyor, the barrels are also exchanged quickly.

Barrel emptying system with NEMO® BH pump

- Medium: Fruit juice concentrates

- Throughput volume: 11.6 m³/h

- Rotary speed: 188 rpm

- Pressure: 12 bar