EMULSION EXPLOSIVES

Highest Safety: Pumping Emulsified Explosives

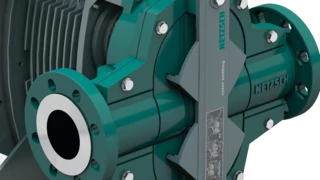

NEMO® progressing cavity pumps convey gently and in compliance with ATEX

Safety has the highest priority in mining. To ensure this at all times, emulsified explosives are increasingly being used. In this case, the volatile components are mixed directly on site at the borehole. However, unique pumps are required to convey emulsified explosives while maintaining the highest safety precautions.

As a global specialist in complex fluid management, NETZSCH Pumps & Systems offers you unique pumps for pumping emulsified explosives. We show you how to pump your emulsified explosives in compliance with ATEX.

Individual Consulting

Emulsified explosives: Pumps for mixing the ingredients on site

The requirements for explosives have been changing. Higher performance and increased safety are the overriding objectives which are demonstrated above all in the greater use of emulsion explosives. In Switzerland alone – traditionally a country with a great deal of tunnel construction – the ratio changed between 1998 and 2005 from 100 percent explosives in cartridge form to 95 percent pumped emulsions. The benefits are huge: the components, which are not dangerous individually, are not mixed until they are on site. The finished mix fully uses the whole borehole, but also goes into small openings. Certainly, high-performance, customized pumps which meet the special challenges of the emulsion matrix or of the explosive are the basis for this.

How to pump emulsified explosives with maximum safety

However, this explosive requires special pumping conditions. For example, the Employer's Liability Insurance Association regulations (BGV) for solid uniform explosives and volatile oils stipulate that the pumps should prevent dangerous stressing of the substance or segregation of the emulsion. Therefore, in addition to the highest safety precautions, gentle pumping is one of the basic requirements when pumping emulsified explosives. The pump expert NETZSCH has developed unique systems for mobile mixed-loading vehicles to pump emulsified explosives. This allows you to pump your components while maintaining maximum safety.

ATEX-compliant: Innovative progressing cavity pump for emulsified explosives

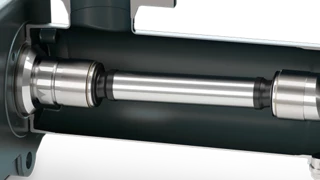

The proven NEMO® SY progressing cavity pump has been reworked to deliver emulsified explosives in vast areas. As a result, it offers you the necessary inspection options and safety measures. The most significant difference to conventional designs is the two inspection openings fitted above the coupling rod’s joints. These allow you to check whether the joints are still sufficiently lubricated and whether the seals are still intact, even during operation. By constantly checking, you prevent dangerous heat build-up from metal-on-metal friction.

The pumps for emulsified explosives are manufactured according to your requirements and compliant with ATEX. Thanks to the numerous different rotor/stator geometries, the pump can easily be adapted precisely to your application. Due to its design, it also delivers particularly gently. In addition, the NEMO® progressing cavity pump allows you to dose the emulsified explosives in proportion to the speed. This way, you can pump your volatile components in mining while observing the highest safety precautions.

NEMO® SY with bearing housing and free shaft end

- Medium: Emulsion explosives

- Pressure: Maximum 72 bar

- Delivery rate: Maximum 130 m³/h