biogas

How Pumps Optimize Your Biogas Production Process

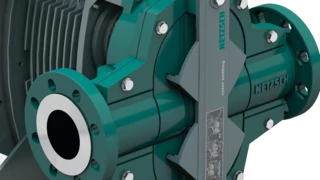

High mixing performance thanks to NEMO® B.Max progressing cavity pump

The conditions in biogas production are extremely challenging for pumps. Many pump systems are not up to the sometimes harsh and abrasive mass and thus do not deliver the required mixing performance. NETZSCH Pumps & Systems, the global specialist in handling complex media, has developed a special pump for the biogas sector.

We will show you how to increase the mixing performance by using a NEMO® B.Max progressing cavity pump and thus optimize your process.

Individual Consulting

Pumps for efficient energy generation with biogas

The boom of environmentally friendly power and heat generation from renewable biomass continues. Especially countries such as the UK, France, Japan or the US discovered the advantages of renewable energies, primarily the use of biogas. The required expertise and the systems are exported from the technology leaders in Germany, like the conveyor technology specialist NETZSCH. The company manufactures progressing cavity pumps which are especially designed for the difficult substrate mixtures in the biomass sector. These pumps can convey and mix even products with a high content of dry matter. In addition to energy plants, these also allow waste from agriculture and food production to be efficiently converted into energy.

Dry biogas substrates pose a challenge for pumps

The greatest challenge in biogas production is the composition of the used substrate. Drier ingredients such as chicken manure restrict the flow, plant fibers from grain waste, corn or grass promote clogging while corrosive manure corrodes the materials. Another issue is that other countries often use bio-waste for gas production instead of the renewable raw materials used in Germany. If the bio-waste contains meat or slaughterhouse waste, it has to undergo hygiene treatment for epidemic protection which can result in high product temperatures of up to 80 °C.

NEMO® B.Max progressing cavity pump optimizes mixing

The NEMO® B.Max progressing cavity pumps from NETZSCH, specially designed for the complex substrate mixtures in the biomass sector, make it possible to reliably convey and mix even product with a high dry matter content. Using them ensures the continuous feed to the fermenter required for an undisturbed fermentation process, despite challenging conditions. With the NEMO® B.Max pump series, NETZSCH has adapted the proven progressing cavity technology to the unique requirements of biogas production. The B.Max pump has a position-optimized feed nozzle that directs the re-circulation into the mixing area against the conveyance direction. This creates turbulence in the biomass, which ensures that the individual materials are already mixed when fed in.

To still provide a continuous supply to the fermenter to ensure an uninterrupted fermentation process under these difficult conditions, NETZSCH has adapted its proven progressing cavity pump technology, the NEMO® B.Max pump range, for these special requirements. To achieve this, the pump is equipped with a position-optimized feed neck which guides the recirculated mass against the direction of flow into the mixing area. This creates turbulence in the biomass which allows an individual blending during feeding. This process is additionally supported by the coupling rod in the blending chamber which is equipped with a screw conveyor. The feeding screw ensures the biomass to be transported into the pump, even in case of high viscosity. The offset segments of the mixing screw and their high thread pitch ensure that more substrate flows to the progressing cavity chambers. The result is an intentional, controlled return flow to create an over feeding, which results in a high efficient homogenization. Depending on the design, pumps of this type achieve an output of up to 70 m³/h and a pressure of up to 48 bar. The continuous supply to the fermenter which ensures an uninterrupted fermentation process makes it superfluous to use a stronger agitator in the NEMO® B.Max.

NEMO® B.Max mixing pump in block design

- Product: Grain waste, corn, grass, chicken manure or slaughterhouse waste

- Temperature: Up to 80 °C

- Capacity: Up to 70 m³/h

- Pressure: Up to 48 bar