thickened sludge

Pumping of Abrasive Sludge From Sewage Treatment Plants

Reduced maintenance and servicing costs thanks to NEMO® progressing cavity pump in FSIP® design

You are a wastewater treatment plant operator and want to pump abrasive thickened sludge reliably? Then you've come to the right place. As a global expert in complex fluid management, NETZSCH Pumps & Systems offers you solutions for pumping thickened sludge that is individually optimized to your requirements.

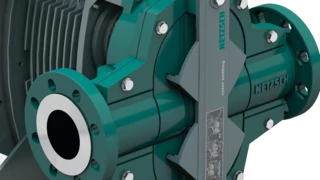

We will show you the advantages of the NEMO® progressing cavity pump in FSIP® design ("Full Service-in-Place") with an xLC® stator adjustment system when pumping abrasive thickened sludge from wastewater treatment plants.

Individual Consulting

Reliable pumping of thickened sludge from wastewater treatment plants

A waste water treatment plant in Bavaria relied on the use of a progressing cavity pump to convey thick sludge with a solid content of eighth percent to an intermediate tank for disintegration. The pump showed a high level of wear due to the abrasive content of the sludge. “Because the solids ratio is over 8 percent, this unit was subject to a particularly high level of wear,” the water treatment manager at the plant explains. “The special texture of the product is probably also a factor in this: It contains iron and aluminum salts from the tertiary sludge and also iron from a local industrial plant.” The rotor-stator pairing therefore had to be serviced approx. every 8,000 operating hours.

Abrasive thickened sludge poses a challenge for pumps

For the replacement purchase, it was particularly important to the customer that the new pump would have a significantly higher reliability and longer service life and would be especially easy to service. The customer decided to change the manufacturer and use the service-friendly Full-Service-In-Place® version of a NEMO® progressing cavity pump from NETZSCH, which can be maintained directly on site. The maintenance friendly design features one of the largest inspection covers existing. “The inspection cover is secured with just five screws to the pump housing, and can be removed without any special tools in really short time”, Mikael Tekneyan, development engineer at NETZSCH, explains. The NEMO® pump is additionally equipped with the xLC® adjustment unit which allows amendments of the iFD-Stator® 2.0 to multiply its service life. During field-testing's lifetime increased by the factor three to four, depending on the product.

Progressing cavity pump reduces costs for thickened sludge pumping

NETZSCH found the right pump for reliably pumping abrasive thickened sludge in the wastewater treatment plant. The NEMO® progressing cavity pump in FSIP® design is particularly maintenance-friendly and robust. Thanks to its innovative design, you can perform maintenance and service without removing it from the plant. This saves you up to 66 percent time. The NEMO® pump used in the wastewater treatment plant in Bavaria is also equipped with the xLC® stator adjustment system, which allows the iFD-Stator® 2.0 to be readjusted and its service life multiplied. Beyond the previous service life, the pump can operate for 16,000 hours before the stator needs to be replaced.

The progressing cavity pump runs 24 hours a day and achieves over 8,000 operating hours yearly at a flow rate of 1-3 m³/h. The advantages of the NEMO® progressing cavity pump in FSIP® design with xLC® stator adjustment system have tripled the service life when pumping thickened sludge and significantly reduced maintenance and servicing costs.

NEMO® progressing cavity pump in FSIP® design

- Product: Sludge with a solids content of 8 %

- Flow rate: 1 to 3 m³/h

- Operating hours: 24 h a day reaching over 8,000 operating hours a year