Bakery Products

How to Increase Service Life and Safety When Pumping Bakery Products

This is how you benefit from NETZSCH pumps when pumping bakery products

Croissants, biscuits, doughnuts - who doesn't love them? As popular as baked goods are, their production often poses unexpected challenges. This is precisely what a southern German company for confectionery products faced when pumping the bakery products.

Together with the global specialist in complex fluid management, NETZSCH Pumps & Systems, the company found a sustainable solution for pumping bakery products. We will show you how to pump your bakery products safely and in compliance with the highest hygiene standards in the future.

Individual Consulting

Pumping bakery products: These challenges must be overcome

The southern German company was challenged to pump bakery products with a high proportion of protein and sugar from a container into molds in precisely metered quantities. The bakery product pumps used up to now could not guarantee a continuous mixture supply. This is due to the unique properties of the product. For example, its specific weight is significantly lower than that of water. In addition, the biscuit mass has an abrasive effect on the pumps. The reason for this is the sugar crystals it contains. This leads to an additional load on the conveying systems, not to mention the high demands on hygiene and food safety. Together with NETZSCH, the company found the optimal solution for effectively pumping the bakery mass and was thus able to optimize the process.

How to increase the dosing accuracy when pumping bakery products

The intention of the company is to convey a pastry mixture with a high proportion of egg white and sugar from the receiver tank and precisely meter it into molds. However, the infeed of the mixes, whose specific weight is considerably below that of water, cannot be guaranteed. In addition, the product has a somewhat abrasive effect due to the sugar crystals it contains and this puts additional stress on the conveying system – quite apart from the high demands in terms of hygiene and food safety.

Pumping bakery products: Easy cleaning & highest hygiene standards

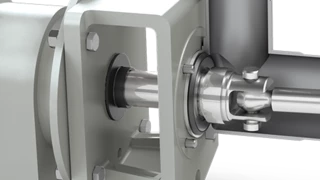

Hygiene plays a decisive role in the food industry, including pumping bakery products. For this reason, NETZSCH developed an innovative solution for power transmission between the drive and the rotor, which also benefits the southern German company for confectionery products. Due to the complex medium, the power transmission in the NEMO® SH Plus hygienic pump takes place via a flexible rod. Open joints would wear out quickly due to abrasion, and joints filled with oil are prohibited regarding food safety. Therefore, the choice fell on the flexible rod hermetically sealed at both ends with the connection points. The ingress of impurities is thus excluded. It also works without moving parts, friction surfaces and lubrication. This gives you high operational reliability and a long service life with low maintenance costs.

In order to cover this range of requirements, the company decided on a NEMO® hygienic pump. Thanks to progressing cavity technology, these pumps, depending on their size, are capable of metering to an accuracy of between five and three percent, irrespective of the consistency of the product, with smaller dispensers even achieving a volumetric accuracy of one percent. This is made possible by the geometrical rotor-stator pairing which produces conveying chambers keeping the same shape during rotation. The same quantity of product is reproducibility transported in these chambers, which means the volume can be continuously adjusted via the speed. In this way the company can now precisely meter between 450 and 3,500 liters per hour of baking mix into the baking molds at one bar.

Due to the difficult product, power transmission between drive and rotor in the hygienic pump is achieved via a flexible rod. Whereas open joints would be quickly worn by abrasion and closed joints filled with oil are not permitted with food safety in mind, the flexible rod is heat-shrunk with the connection points to form a hermetic seal at both ends and functions without moving parts, friction surfaces and lubrication. This means high operational reliability and a long service life are achieved with low maintenance costs.

The fact that the pump does not need to be dismantled for cleaning also contributes to this. The streamlined geometry of the conveying area with no dead spaces allows direct cleaning in place. This involves the bakery company using hot water at 60 °C to flush the pump for 20 minutes at 400 rpm. The special design and the materials used – above all stainless steel and highly robust elastomers – mean the lobe rotors do not get damaged in the process.

NEMO® SH plus hygienic pump with bearing housing

- Medium: Pastry mixture

- Throughput volume: 450 and 3,500 liters per hour

- Pressure: 1 bar