fpso

How to Pump Crude Oil Efficiently and Safely on Your FPSO

NETZSCH supplies various pump technologies from a single source for safe oil production on mobile platforms

Pumping using floating production storage and offloading unit, or FPSO for short, offers a high degree of flexibility for operators in terms of the place of extraction. Since the unit handles the pumping, storage, cleaning and loading of the extracted crude oil, the demands on the pumps could not be more different.

As a global specialist in complex fluid management, NETZSCH Pumps & Systems has successfully equipped an FPSO with various positive displacement pumps. We will show you the advantages of obtaining all pumps for an FPSO from a single source from NETZSCH.

Individual Consulting

FPSO enables efficient and cost-effective oil production

The world's oil reserves are limited and cannot be exploited ad infinitum. This puts all the more pressure on the producing companies to make production as efficient and cost-effective as possible. The development of new oil fields is often associated with immense expense, so operators of offshore wells nowadays mostly opt for using FPSOs. FPSOs are ships that take over the function of an oil platform. They extract, store, clean and load the extracted crude oil. The decisive advantage is that, compared to an oil production platform, they can be used flexibly and independently of location. This makes expensive pipelines from the extraction site to the deposit superfluous, and smaller, less productive oil fields can still be operated cost-effectively.

Many different pumps for oil production on FPSO, and one solution: NETZSCH

In January 2018, one of the world's largest oil companies decided to deploy just such a flexible production unit off the coast of Great Britain. Once the planned eight boreholes have been drilled, the FPSO will be one of the largest investments the group has made in the British North Sea for decades. Up to 45,000 barrels per day will be produced at the new site in the future. Efficient operation is important to the company, especially in view of volatile oil prices, so the company wanted the system to be profitable even at world market prices of less than 40 US dollars per barrel.

Efficiency is therefore also a priority for the technology used on the platform, both for the primary tasks associated with oil production and for secondary processes such as crude oil processing. The oil company's partner in charge of engineering and construction therefore turned to NETZSCH Pumps & Systems for the pumping technology. NETZSCH not only has a comprehensive portfolio of technology for pumping liquid products, it also has the required expertise in the oil and gas industry. NETZSCH is familiar with the challenges involved in pumping a wide range of products for the industry and offers the right solution for every application. The portfolio includes special technologies for extending the life of oil wells that are drying up, for increasing the efficiency of existing oil fields, and for the safe and efficient production of low-quality or high-viscosity crude oil. "We do especially well in the offshore sector– not least because NETZSCH concentrates its combined knowledge of the industry and its applications in a specialized business field with a global presence," says Ulrich Eibl, Head of the Oil & Gas Mid-/Downstream global business field at NETZSCH Pumpen & Systeme in Germany.

Eibl also knows that, on the high seas especially where every repair job comes with enormous costs, customers need very low-maintenance technology that functions simply, is reliable and has long life cycles. "After all, downtime on an FPSO quickly adds up to several million US dollars in losses per day", the pump expert explains. Eibl is also familiar with the dimensioning requirements, as every inch of space is used to operate platforms as efficiently as possible. The pumping system must therefore also have as space-saving a design as possible.

NETZSCH enables efficient oil production from a single source on FPSO

Three different pump types from NETZSCH are used on the FPSO. The TORNADO® T.Proc® rotary lobe pump cleans the marine diesel oil. This process is necessary to protect the engines and tanks on the FPSO. "Since maintenance and cleaning of all components is expensive and time-consuming at a remote site such as an FPSO, the fuel for the energy supply is cleaned in a separator", explains Ulrich Eibl, Business Field Manager Oil & Gas Mid- / Downstream at NETZSCH. This keeps the engines and tanks clean, ensuring a long service life for the components.

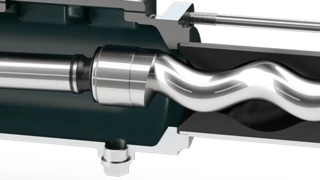

In another area of the ship, several NOTOS® multi screw pumps handle another crucial task. "Safety has top priority for our customers", emphasises Eibl. To prevent an explosive atmosphere from developing in the crude oil storage tanks, a gas is produced from part of the ship's diesel fuel, which is superimposed on the oil in the tanks. Here, the three-spindle pumps safely convey the diesel to the area where the gas is produced.

In addition, several NEMO® progressing cavity pumps are used in another area. They handle the pumping of dirty water, so-called produced water. "You can't talk about dirty water in the classic sense here", explains Eibl. "It is 50 to 60 °C hot water that comes to the surface with the extracted crude oil." The unique feature is that in addition to oil droplets, the water also contains small rock particles from the seabed, hydrogen sulphide and chlorides. "Since the hydrogen sulphide has a toxic effect, leakages must be avoided at all costs", Eibl continues. The particularly robust API (American Petroleum Institute) design of the NEMO® pumps reduces this risk to a minimum and increases the service life.

Through concentrated expert know-how in a specialised business field and excellent service, NETZSCH was able to convince the operators of the FSPO. All models have been in successful operation since commissioning.

TORNADO® T.Envi® rotary lobe pump, NOTOS® multi screw pump, NEMO® BY progressing cavity pump

- Medium: Diesel and produced water

- Temperature: 15 to 60 °C

- Flow rate: 0.9 to 6 m3/h

Literature

- NEMO® Progressing Cavity PumpsBrochure

- TORNADO® Rotary Lobe PumpsBrochure

- NOTOS® Multi Screw Pumpsbrochure

- Oilfield PumpsBrochure

- API 676 3rd EditionBrochure

- MultiProtector: The Monitoring and Protection UnitBrochure

- Large Capacity PumpsBrochure

- The Perfect Pipeline PumpBrochure

- Customer Service/AftermarketBrochure

- Product PortfolioBrochure