Chocolate

How to Pump Chocolate Gently at a Constant Temperature

With this NETZSCH pump, you produce chocolate of the highest quality

Unsteady temperatures, viscosity fluctuations and thus destroyed chocolate consistency sounds familiar? NETZSCH Pumps & Systems is the right choice if you struggle with these challenges daily.

As a global specialist in complex fluid management, we offer you pump solutions for conveying particularly challenging media such as chocolate. We will show you how to increase the quality of your chocolate by using NETZSCH pumps.

Individual Consulting

How pumps affect the quality of chocolate

We all know and love chocolate, but hardly anyone is aware of the challenges of manufacturing. Statistically, every German citizen eats around 9.5 kg of chocolate in bars, hollow figures, pralines and other similar products every year. Consumption rises sharply, especially at Easter and Christmas. Despite the popularity of chocolate, its production could be more straightforward. One significant influence on the chocolate’s quality is the pumps used in its production. High shear loads, for example, can cause abrasion and damage to the chocolate, affecting its texture and appearance. In addition, chocolate must be pumped at certain temperatures to maintain consistency. The quality of chocolate can also be negatively affected if the pumps cause a change in viscosity or if residues and impurities remain due to the poor cleanability of the pumps.

What you need to bear in mind when pumping chocolate

The secret of high-quality chocolate is the optimal configuration of the fat crystals they contain, which depends directly on the tempering. If it is too high or too low, the mass no longer melts on the tongue or does not have an appealing gloss but appears milky and dull. In addition, the viscosity changes with the crystal content, which can lead to problems during further processing and filling. Tempering, therefore, is decisive for the quality. That's why pre-crystallised chocolate requires gentle conveying at a constant temperature. Thus, the global specialist in complex fluid management provides a pump that covers all these requirements.

How to pump chocolate at a constant temperature

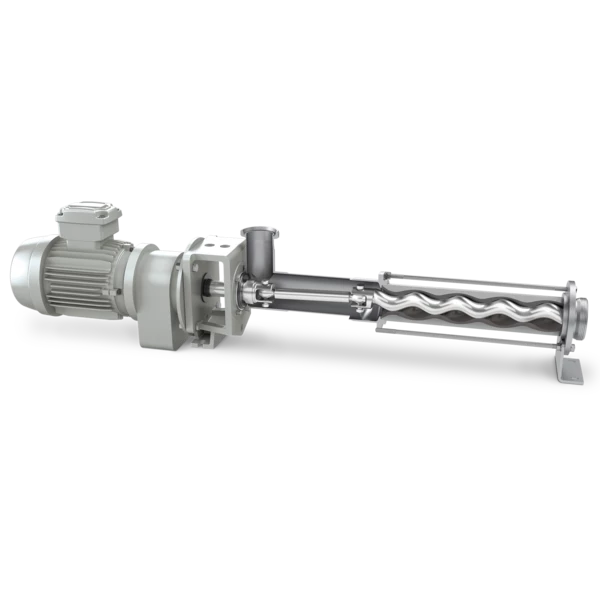

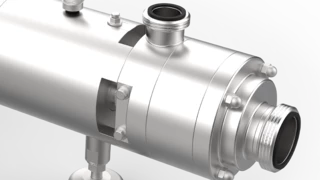

The solution is called: NEMO® BH hygienic pump in compact block design with an adjustable heating jacket. Thanks to its innovative design, the progressing cavity pump guarantees gentle pumping. The technology is based on the coordinated geometries of a helical rotor and its surrounding stator. Due to the size of the chambers and the low sliding speeds of the rotor, even larger solids, such as nuts or brittle, can be conveyed without damage. In addition, thanks to the heating jacket, you can regulate the temperature of the chocolate and keep it constant. The heating jacket surrounds the pump from the mechanical seals over the entire length to the discharge nozzle. This prevents temperature fluctuations and the associated reduction in quality.

The progressing cavity pumps from NETZSCH also offer you CIP - "Cleaning-In-Place" and SIP - "Sterilisation-in-Place". Using this, you can clean or sterilise the pump without removing it from the system. This prevents residues and contamination. By the way, you save time and money during cleaning. Poor quality due to fluctuating conveying conditions when pumping chocolate is now a thing of the past. What are you waiting for? Get a consultation from the experts at NETZSCH now and pump gently at a constant temperature in the future.

NEMO® BH hygienic pump in compact block design

- Medium: Chocolate

- Capacity: 25 m³/h

- Pressure: Max. 12 bar