Chocolate

How to Pump Chocolate Gently at a Constant Temperature

With this NETZSCH pump, you produce chocolate of the highest quality

Unsteady temperatures, viscosity fluctuations and thus destroyed chocolate consistency sounds familiar? NETZSCH Pumps & Systems is the right choice if you struggle with these challenges daily.

As a global specialist in complex fluid management, we offer you pump solutions for conveying particularly challenging media such as chocolate. We will show you how to increase the quality of your chocolate by using NETZSCH pumps.

Individual Consulting

Confectioneries & Bakeries

It has been over 10,000 years since the beginning of grain cultivation. The understanding of the use of grains has been an important evolutionary process in human history. It was not until the invention of the oven and the discovery of the effect of yeast that finally made bread a staple food in people's diets. Not only did the Egyptians cultivate yeast for use in baking, but it was also in Egypt that refinements to the oven were made. Five thousand years ago, over 30 different types of bread existed in Egypt. From there, the art of bread making found its way into Europe through Greece and the Roman Empire. It was finally in Europe where the largest variety of breads were developed over the centuries.

What you need to bear in mind when pumping chocolate

Bakery products fall into three general categories: bread loaves, smaller bread products (such as pretzels, rolls, or croissants) and pastries (such as cookies, cakes, or pies). Each of these catagories requires special dough, ingredient treatment and supervision.

How to pump chocolate at a constant temperature

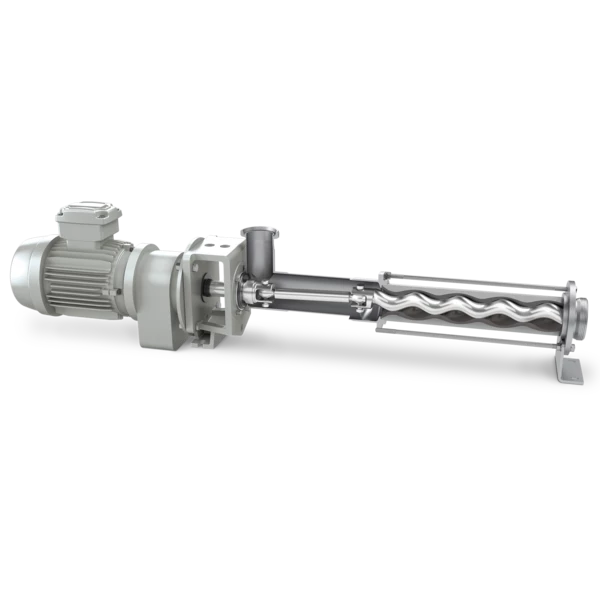

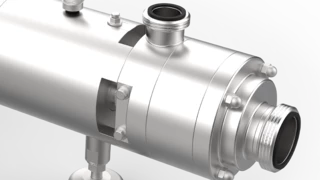

The solution is called: NEMO® BH hygienic pump in compact block design with an adjustable heating jacket. Thanks to its innovative design, the progressing cavity pump guarantees gentle pumping. The technology is based on the coordinated geometries of a helical rotor and its surrounding stator. Due to the size of the chambers and the low sliding speeds of the rotor, even larger solids, such as nuts or brittle, can be conveyed without damage. In addition, thanks to the heating jacket, you can regulate the temperature of the chocolate and keep it constant. The heating jacket surrounds the pump from the mechanical seals over the entire length to the discharge nozzle. This prevents temperature fluctuations and the associated reduction in quality.

In modern baking establishments and industrial bakeries, NEMO®Progressing Cavity Pumps plays an established role in a variety of demanding handling requirements. For example, special designs are available for the transport of chocolate and marzipan. NEMO®Hygienic Pumps can handle sensitive yeast mixtures. In addition to the various doughs and batters, NETZSCH pumps can transport fats, oils, honey, egg mixtures, fruit juices, flavoring agents, glucose, almond pastes, nut pastes, fruit, gelatin, fillings and other ingredients. The optimal pump type selection depends upon the properties of the substance in the respective stage of the production process. Our experts will find you the perfect solution for your application.

NEMO® BH hygienic pump in compact block design

- Medium: Chocolate

- Capacity: 25 m³/h

- Pressure: Max. 12 bar