Oil-Water Mixture Pump

Energy-efficient and cost-effective Pumps for Upstream Oil-Water Mixtures

Progressing cavity pump from NETZSCH significantly increases efficiency in the oil-water mixtures upstream fields.

Sustainability is playing an increasingly important role in oil production. More efficient use of existing oil fields is increasingly coming into focus. New oil fields are no longer being brought on stream randomly. State-of-the-art extraction technologies play a decisive role here.

As a global specialist in complex fluid management, NETZSCH Pumps & Systems has successfully equipped an oil field in Bramberge, Emsland, with a special progressing cavity pump. We will show you how to benefit from using a downhole progressing cavity pump from NETZSCH in oil production and what the future oil field will look like.

Individual Consulting

Disadvantages in oil production due to energy-intensive pumps

The oil demand continues unabated despite climate change. However, state-of-the-art technologies enable more efficient oil production in existing oil fields so that new production sites are kept from being opened daily, and the environment is further polluted. Neptune Energy Deutschland GmbH was also challenged by more efficient production. At one of its sites in the Bramberge oil field in the Emsland region, an oil-water mixture with a high gas content was brought to the surface using the gas lift principle. In this process, associated gas is injected into the well's riser under high pressure, pushing the oil-water column to the surface. This method proves very reliable, but since it is very energy-intensive, it has low efficiency. Due to the high energy input, this method is correspondingly expensive.

Low efficiency in oil production with gas lift process

Therefore, those responsible decided to change the production technology and contact the global provider of complex fluid management, NETZSCH. "The challenge was to offer a technical solution that is just as reliable as the gas lift process and at the same time particularly flexible", says Jörg Eitler, head of the global business field oil & gas upstream at NETZSCH. "The system had to be adaptable to the changing boundary conditions in operation even when installed directly in the well", he continues. In addition, the new system had to ensure a pressure of ten bar at the surface. Furthermore, the operator needed reliable pressure and temperature data from a depth of about 1,000 m in the borehole.

Oil production 4.0: Advantages of NETZSCH downhole progressing cavity pumps

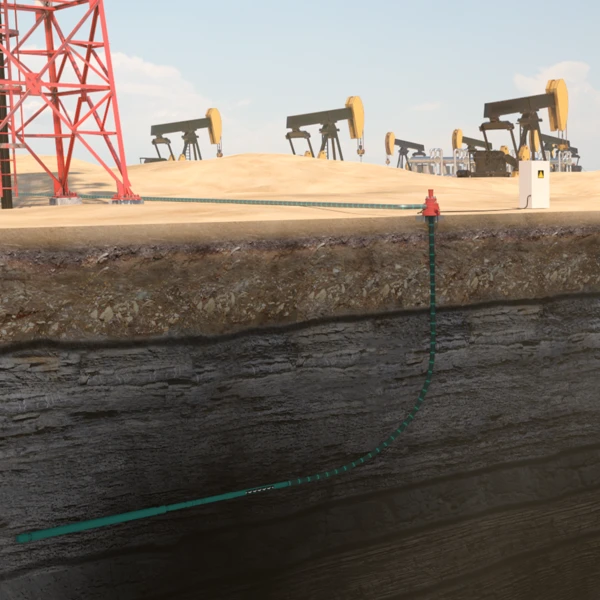

Based on this requirement profile, the experts from NETZSCH recommended an underground-driven progressing cavity pump, a so-called electric submersible pumping system (ESPCP). The system's unique design makes it significantly more energy-efficient than other systems. The rotor is not driven by a rod from an above-ground drive head. The pumping elements and the motor are sunk into the borehole. A unique underground bearing housing absorbs all radial and axial forces of the rotor. The system has been equipped with various pressure, temperature and vibration sensors to react optimally to changing conditions in the borehole. This provides essential data on the dynamic level of the fluid in the borehole and allows you to make appropriate adjustments to the pump. This ensures optimal pumping at all times despite changing conditions.

The installation of the ESPCP pump system at a depth of approximately 1,000 m and its commissioning took place in 2019. Since then, it has been in operation to the complete satisfaction of the oil field operator. By reducing energy consumption, it was not only possible to achieve significant cost optimisation, but the system also represents an essential step towards the digitalisation of oil fields. "Particularly in marginal wells/fields, pressure information in the well or constant monitoring of the dynamic fluid level is the key to successful field operation. Especially when the oil price on the world market is low, this data can be a decision criterion for the further operation of heavily diluted fields. This is oil production 4.0", Eitler sums up.

ESPCP Pump System

- Medium: Oil-water mixture with gas content up to more than 90 %

- Throughput volume: About 9 m³ oil per day

- Pressure: 10 bar at the surface

- Rotation speed: 100-500 rpm

- Operating depth: Approx. 1,000 metres below the surface