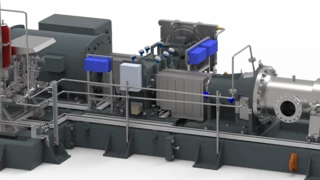

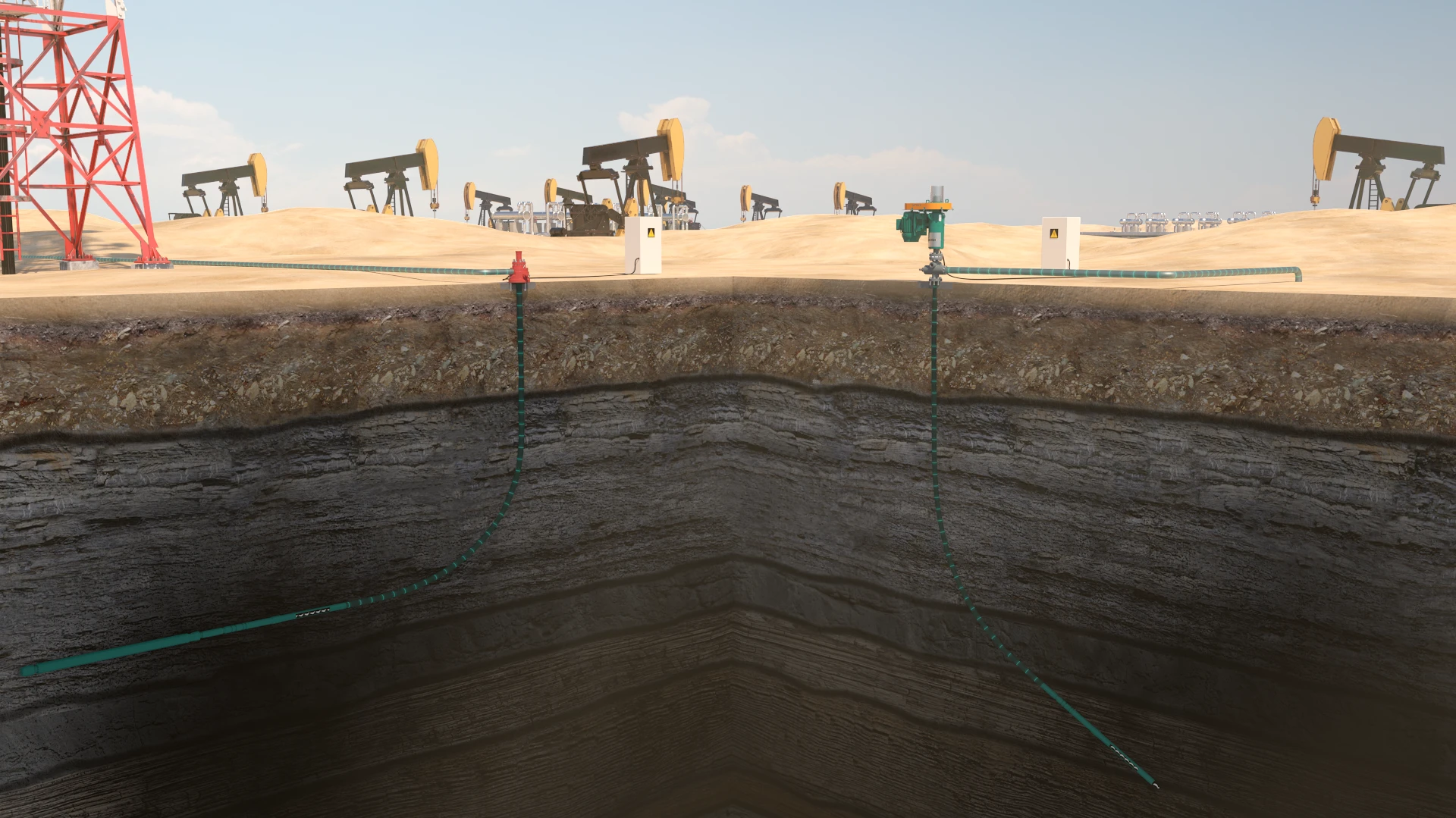

Energy savings, high reliability, and permanent monitoring of the dynamic fluid level: No other system worldwide offers all of this in oil and gas production except for the Electrical Submersible Progressing Cavity Pump (ESPCP) systems from NETZSCH. They are particularly suitable for highly deviated wells and offshore applications.

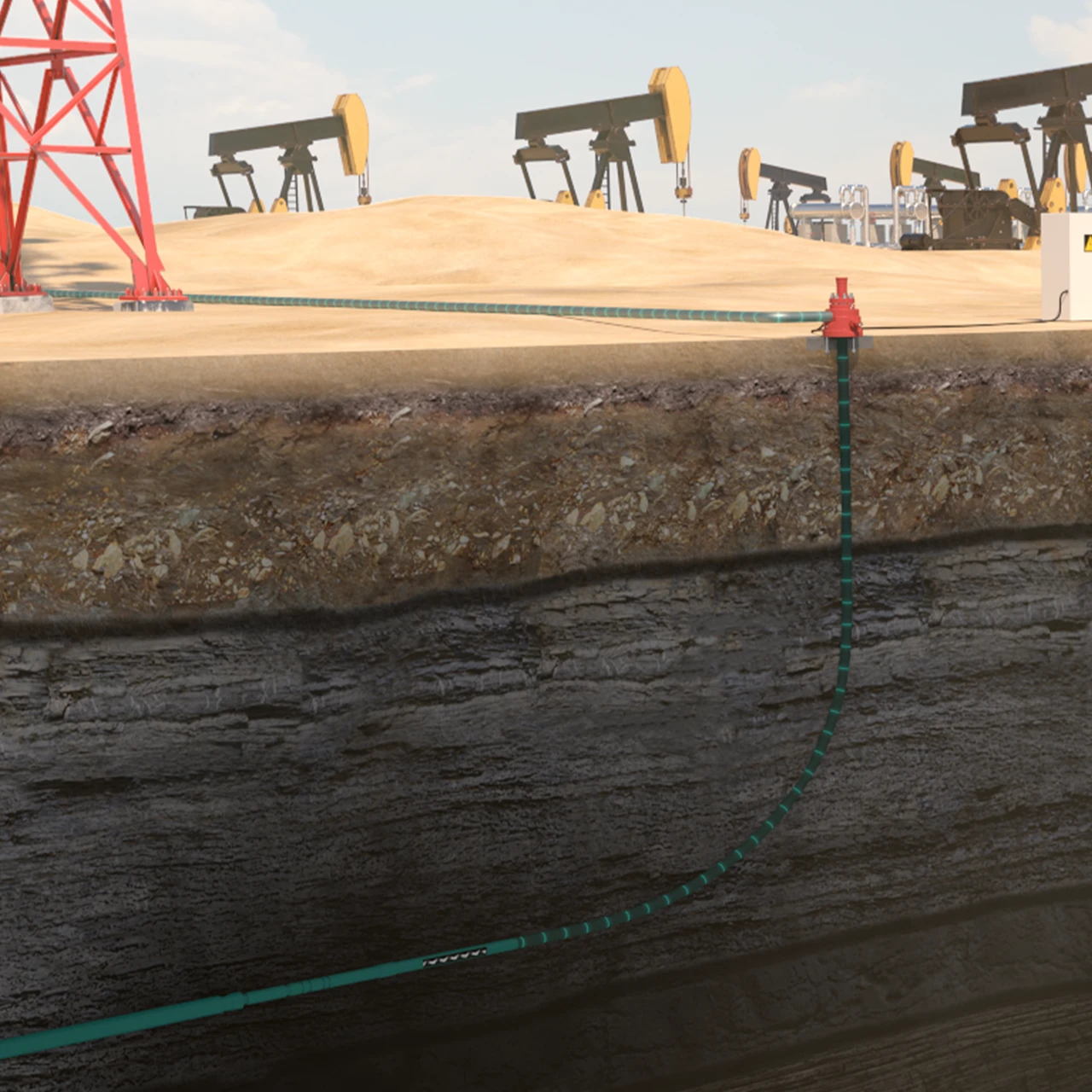

ESPCP is the abbreviation for Electrical Submersible Progressing Cavity Pump. The rodless system combines the advantages of a submersible permanent magnet motor (PMM) with those of PCP technology. By removing the sucker rod and driving it with a downhole engine, an alternative PCP system is created. This avoids the typical problems of disconnected sucker rods and pipe failures.

Electrical Submersible Progressing Cavity Pump (ESPCP) System: Energy-saving and highest reliability

The ESPCP pump system is an energy-saving solution with excellent reliability in all applications. It is equipped with numerous downhole sensors. They provide information on the pump’s pressure, temperature, vibration, and motor temperature.

Hence, you can continuously monitor the fluid level and react to possible changes as quickly as possible. It also enables high flow rates in complex (deviated and horizontal) wells and fluid conditions. In addition, the ESPCP progressive cavity pump system reduces your operating costs thanks to its low failure rate.

Advantages

Maintenance

Sensors

Innovative design

Technique

Worldwide service and support for your pump and system

Our service and support do not end with the purchase. From consultation, spare parts and maintenance to the repair and modernisation of your pump - we support you right from the start.

Thanks to our worldwide service network, we are ready for you around the clock in case of an emergency.

Your contacts and companies at NETZSCH

Any specific questions? Contact us for help or fill in the contact form.